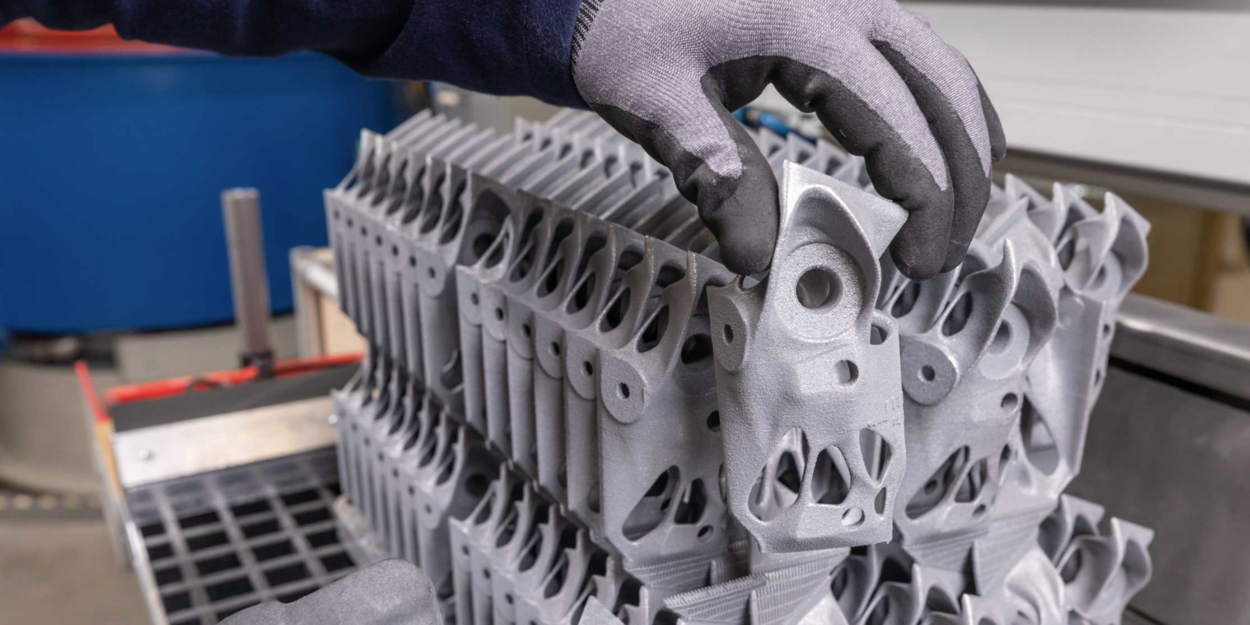

Banner Image Courtesy of BMW

The automotive industry has always been a proving ground for innovation. From the earliest assembly lines to today’s electric and autonomous vehicles, every leap forward has been driven by new technologies and smarter materials. Among the most transformative of these is 3D printing, which has shifted from a prototyping tool into a powerful method for producing functional, end-use car parts.

But while 3D printing opens the door to speed, customization, and cost efficiency, the choice of material ultimately determines whether a part succeeds or fails. A bracket that holds up under stress, a trim piece that looks showroom-ready, or a gasket that resists heat and oil—all of these depend less on the printer itself and more on the material selected.

With multiple 3D printing processes available, the range of materials is broader than ever. Each has unique strengths, limitations, and ideal use cases. This article explores how to choose the right material for 3D printed car parts, focusing on six key considerations: structural strength, heat and chemical resistance, precision and finish, flexibility, and application-specific performance.

Structural Strength & Durability

When it comes to automotive parts, strength is non-negotiable. Components must withstand vibration, impact, and long-term wear. The right material ensures that parts don’t just look good—they perform reliably on the road.

FDM (Fused Deposition Modeling)

• Materials: ABS, Nylon, and carbon-fiber reinforced filaments.

• Use Cases: Prototypes, brackets, jigs, and fixtures.

• Strengths: Affordable and accessible, with reinforced filaments offering excellent stiffness-to-weight ratios.

SLS (Selective Laser Sintering) & MJF (Multi Jet Fusion)

• Materials: PA12, PA11, and glass-filled nylons.

• Use Cases: Functional housings, clips, and lightweight structural parts.

• Strengths: High durability, isotropic strength, and resistance to fatigue.

SLM (Selective Laser Melting)

• Materials: Aluminum, stainless steel, titanium.

• Use Cases: Load-bearing parts, engine brackets, and performance components.

• Strengths: True metal strength, enabling parts that rival or surpass traditionally machined components.

Durability is about matching the material to the stresses of the part’s environment. A dashboard clip doesn’t need aerospace-grade titanium, but a suspension bracket might.

Heat & Chemical Resistance

Cars operate in environments that test materials to their limits: under-the-hood heat, exposure to oils and fuels, and constant temperature fluctuations. Choosing a material that resists these conditions is essential.

High-Temperature Polymers (FDM):

• Examples: PEEK, ULTEM

• Strengths: Exceptional thermal stability, making them suitable for engine-adjacent parts.

SLS/MJF:

• Examples: Nylon

• Strengths: Good resistance to oils, greases, and moderate heat. Ideal for housings, ducts, and connectors.

SLM Metals:

• Examples: Stainless steel and titanium.

• Strengths: Outstanding resistance to both heat and corrosion, perfect for exhaust components or turbo housings.

SLA Resins:

While SLA excels in precision, most resins are less heat-resistant. However, specialized high-temp resins can be used for molds or low-stress thermal applications.

In short, thermal and chemical resistance often narrows the field. For parts exposed to extreme conditions, metals or high-performance polymers are the safest bet.

Precision & Surface Finish

Not every car part is about brute strength. Some demand aesthetic appeal, fine detail, or tight tolerances, which depends on both the printing process and the material.

SLA (Stereolithography):

• Strengths: Unmatched surface smoothness and detail resolution.

• Use Cases: Interior trim, knobs, display prototypes, and molds for casting.

MJF/SLS:

• Strengths: Good balance of detail and strength, with slightly textured finishes.

• Use Cases: Functional housings, clips, and parts where both performance and appearance matter.

SLM Metals:

• Strengths: High precision, though post-processing (machining, polishing) is often required for a refined finish.

• Use Cases: Engine components, custom brackets, and performance parts.

For customer-facing or visible components, SLA and MJF stand out. For hidden but functional parts, SLS and FDM may be more cost-effective.

Flexibility & Customization

Cars are complex systems, and not every part is rigid. Some require flexibility, shock absorption, or ergonomic comfort.

SLA Flexible Resins:

• Use Cases: Seals, gaskets, grips.

• Strengths: Smooth finish with tailored flexibility.

SLS/MJF TPU (Thermoplastic Polyurethane):

• Use Cases: Vibration dampeners, hoses, protective covers.

• Strengths: Excellent elasticity, abrasion resistance, and durability.

FDM Flexible Filaments:

• Use Cases: Low-cost prototypes of flexible parts.

• Strengths: Accessible but less consistent than industrial processes.

Performance by Application

Ultimately, the “best” material depends on the intended use of the part:

Prototyping

• Visual Models: SLA resins for smooth, presentation-ready parts.

• Functional Prototypes: FDM (ABS, Nylon) or SLS/MJF (PA12) for testing fit and function.

End-Use Parts

• Plastic Components: SLS/MJF nylons for strength and durability.

• Metal Components: SLM aluminum, stainless steel, or titanium for critical load-bearing parts.

Customization & Aesthetics

• Interior Trim: SLA for smooth finishes, MJF for color options.

• Exterior Detailing: SLS/MJF for durable, weather-resistant parts.

High-Performance Applications

• Motorsport or Racing: Carbon-fiber reinforced polymers (FDM) or lightweight metals (SLM).

• Heat-Intensive Areas: PEEK, ULTEM, or titanium.