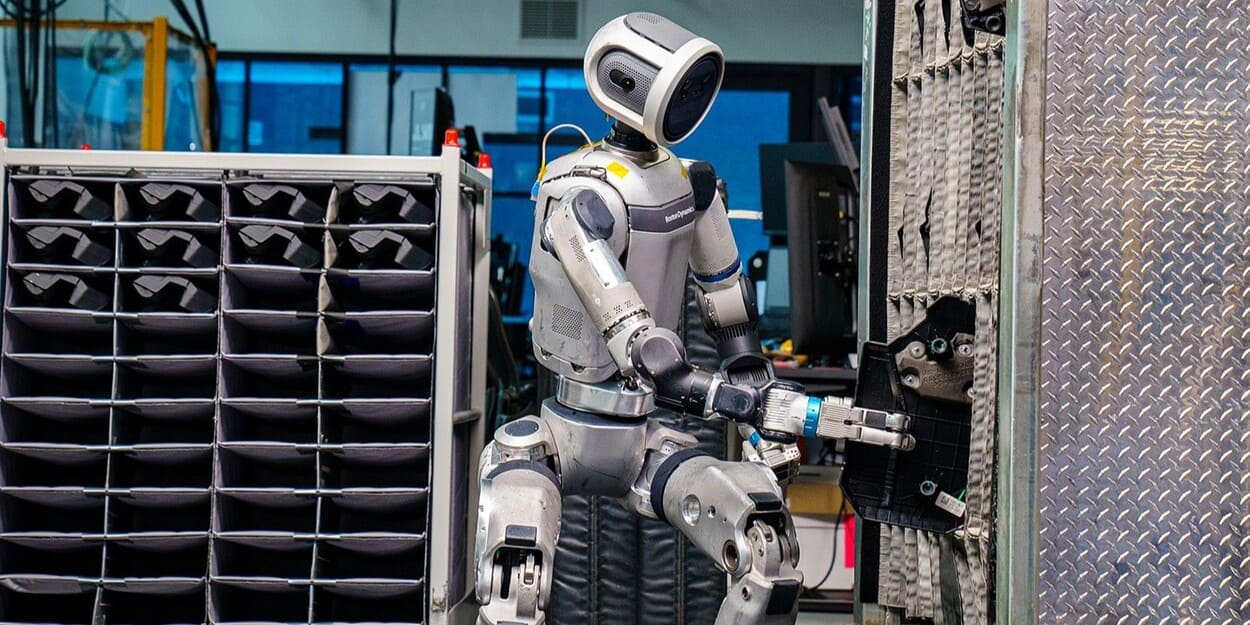

Banner Image Courtesy of Boston Dynamics

In today’s fast‑paced robotics industry, speed is everything. Traditional prototyping methods can slow engineers down, stretching development cycles from weeks into months. That’s where 3D printed robot prototypes shine: they let teams iterate designs in hours, not weeks, and drive rapid prototyping robotics workflows that keep innovation moving. In this article, we’ll explore how 3D printing in robotics eliminates bottlenecks, cuts costs, and unlocks complex geometries—helping you go from concept to working prototype faster than ever before.

The Bottleneck of Traditional Prototyping

Most robotics teams still rely on CNC machining, injection molding, or manual fabrication for early‑stage parts. While these methods deliver strong, precise components, they come with serious drawbacks:

Long lead times: Outsourced CNC or mold tooling can take 4–8 weeks per iteration.

High per‑piece costs: Machining small runs is expensive; tooling amortization drives up quotes.

Limited flexibility: Once a mold is made, design changes mean new tooling—and new delays.

When every day counts, these bottlenecks translate to missed deadlines, inflated budgets, and lost market opportunities. In contrast, 3D printed robot prototypes give you the agility to test multiple concepts in the time it takes a shop to cut one steel bracket.

How Additive Manufacturing Accelerates Robotics R&D

Additive manufacturing flips the script on traditional supply chains by bringing prototyping in‑house:

On‑demand printing – Upload your CAD file, choose materials, and hit “print.”

Speed – High‑end resin, nylon, or metal printers can deliver parts in as little as 4–12 hours.

Material variety – From engineering plastics (PA12, ABS‑like resins) to metal alloys (stainless steel, aluminum), you can match the strength and heat resistance your robot demands.

This seamless 3D printing in robotics workflow eliminates external quotes, shipping delays, and minimum order requirements. Engineers handle the entire process—from slicing to part removal—so they retain full control over schedules and priorities. The result? A lean, self‑sufficient R&D pipeline that thrives on rapid prototyping robotics cycles.

Design Iteration at the Speed of Thought

True innovation happens when you can test ideas in rapid succession. 3D printed robot prototypes enable:

Instant feedback loops: Print a gripper jaw this morning, fit it on your arm by afternoon, and log test data by evening.

Parametric CAD to print: Adjust dimensions in your CAD tool, export STL, and you’re printing—no tooling changes required.

With this agility, teams uncover ergonomic issues, alignment errors, or thermal hotspots early—before they become costly engineering change orders. In essence, every design sprint becomes a rapid prototyping robotics lab, fueled by the immediacy of additive manufacturing.

Cost & Resource Savings

While speed is the headliner, cost savings are the headline:

No tooling fees: Every iteration is just the material cost plus machine time.

Lower per‑part cost: For small batches (1–20 pieces), 3D printing often undercuts CNC once setup and labor are factored in.

Waste reduction: Additive processes only deposit the material you need—unlike subtractive methods that mill away up to 70% of the billet.

Taken together, these efficiencies translate to leaner budgets, fewer scrap parts, and a smaller carbon footprint—key wins for both finance and sustainability teams.

Complex Geometries & Embedded Features

Lattice infill: Optimize weight versus strength by replacing solid cores with engineered lattices.

Conformal cooling or fluid channels: Integrate internal channels directly into motor housings for active thermal management.

Embedded fixtures: Print mounting bosses, snap‑fits, or cable clips right into your robot frame.

These capabilities empower robotics engineers to push boundaries—whether it’s a lightweight drone arm with internal wiring conduits or a gripper finger with a built‑in flexure hinge. By leveraging 3D printing in robotics, you unlock design freedom that accelerates function and performance.

From Prototypes to Production

As additive technologies have matured, the line between prototyping and full-scale manufacturing has all but disappeared. Today’s advanced 3D printers—from high‑throughput polymer systems to industrial metal platforms—are capable of producing hundreds or even thousands of fully functional, end‑use components with consistent quality and tight tolerances. By combining these machines with hybrid workflows—where critical subassemblies are printed on demand and then integrated with traditionally machined or cast parts—companies can optimize both cost and performance. Automated post‑processing solutions, such as robotic depowdering and precision heat‐treatment ovens, further streamline the path from raw build to finished product, making short-run production both practical and economically attractive.

Try Hi3DP’s Nylon and Metal 3D Printing Services to Make Robot Parts

Ready to accelerate your next robotics project? Hi3DP offers:

Nylon PA12 & PA11 for durable, wear‑resistant prototypes.

Aluminum, stainless steel & tool steels for functional testing and short‑run production.

TPU for flexible, abrasion‑resistant parts.

Expert DfAM consulting to optimize your designs for additive workflows.

Fast turnarounds—get parts in as little as 48 hours with our premium services.

Whether you’re iterating a sensor mount, testing a new gripper geometry, or preparing pilot‑run end‑use parts, Hi3DP’s 3D printed robot prototypes deliver the speed, quality, and reliability you need. Visit our service page to upload your CAD files and get a personalized quote today!