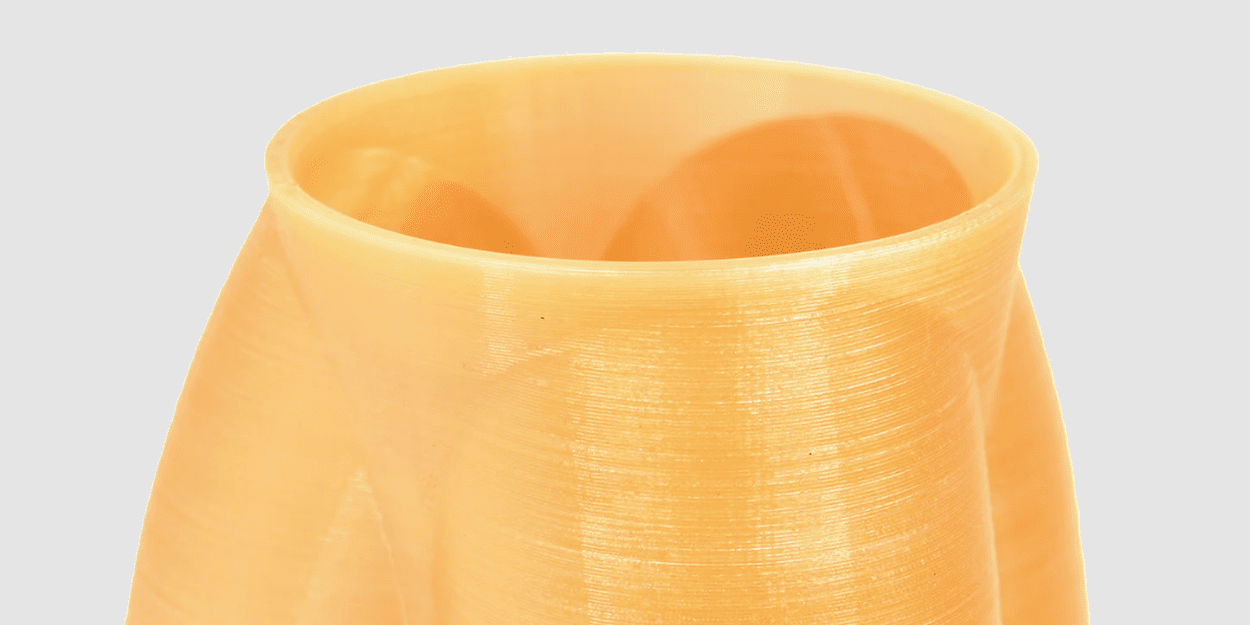

Banner Image Courtesy of 3DXTECH

What is PEKK?

PEKK belongs to the PAEK (polyaryletherketone) family of high-performance thermoplastics. Unlike PEEK (polyetheretherketone), which is typically a homopolymer, PEKK is often produced as a copolymer whose monomer ratio (the ratio of keto/ether groups) can be tuned. That tunability changes melting behavior, crystallization speed and mechanical/thermal performance, which is why different PEKK grades exist for injection molding, extrusion, or additive manufacturing. In short, PEKK gives you many of the “super-polymer” benefits of PAEKs (heat, chemical and wear resistance) with processability options that can be tuned for 3D printing.

Material Properties

Thermal

PEKK is a semi-crystalline polymer with a glass transition (Tg) typically around ~160–165 °C, while published melting ranges vary by grade (commonly ~300–360 °C depending on the formulation). Service and continuous-use temperatures are very high compared with commodity plastics. Parts can often withstand short-term use above 200 °C and continuous service around 200–230 °C for some grades. These thermal numbers are grade-dependent, so always check the datasheet for the specific filament brand/grade.

Mechanical

PEKK shows high stiffness and strength, excellent fatigue resistance and very good wear/tribological behavior. Tensile and flexural strengths rival engineering plastics and, for many applications, approach metal-replacement performance scaled by part geometry.

Chemical and Flame Resistance

PEKK has excellent resistance to many chemicals (acids, bases, oils, solvents) and often exhibits better chemical/oxidative resistance and improved flame/thermal-oxidation stability compared with some PAEK grades. Certain PEKK grades are available with flame-retardant properties for aerospace interiors and related uses.

Crystallinity and Appearance

PEKK grades vary from slower-to-crystallize (more amorphous appearance, easier surface quality) to faster crystallizing (higher crystalline fraction, higher stiffness and thermal stability). The crystallization behavior also strongly affects dimensional stability and requires thermal control during printing.

Printer Settings

PEKK is a demanding material. These are typical starting points; make sure to always confirm with your filament vendor’s datasheet and run small test prints before producing critical parts.

Hotend / Nozzle Temperature

Typical extrusion (nozzle) temperature is ~330–370 °C, depending on grade and printer. Many vendors recommend ~340–360 °C as a practical window for PEKK filaments intended for FFF/FDM. Use a hardened steel or coated nozzle rated for high temps.

Heated Bbed

Heated build plate 120–160 °C is commonly used (some vendors list lower or higher ranges by grade). Proper bed adhesion methods — high-temp adhesives, PEI sheets rated for high temperature, or specialized surfaces — are necessary.

Enclosed Heated Chamber

Enclosure + active chamber heating are strongly recommended. Printing inside an enclosure reduces thermal gradients and warping; many sources recommend holding the chamber temperature near the part’s Tg (or at least substantially elevated) to promote layer adhesion and reduce internal stresses. For PEKK, this often means chamber temperatures in the range ~100–160 °C, depending on the grade and printer capability. Low or no chamber control increases the chance of delamination and warping.

Cooling

Minimize part cooling. PEKK typically benefits from little-to-no forced cooling during printing because cooling promotes crystallization and shrinkage. Use low fan speeds or switch fans off for functional sections.

Print Speed and Layer Height

Moderate speeds (e.g., 10–40 mm/s for large/high-quality parts, faster for small non-critical features) and conservative layer heights help control interlayer adhesion. Slower speeds also help maintain a steady thermal profile through each deposited bead.

Supports

Specialized high-temperature support materials are needed (some system vendors offer compatible support compounds). If soluble supports are required, confirm chemical compatibility at PEKK processing temperatures — not all soluble supports survive those print conditions.

Nozzle / Mechanical

Use hardened nozzles and a high-quality high-temp hotend assembly. PTFE liners are not suitable at PEKK melt temps; use all-metal hotends.

Post-processing / Annealing

Semi-crystalline PEKK parts often benefit from controlled post-print annealing to increase crystallinity, stabilize dimensions and boost mechanical properties. Anneal following vendor recommendations (temperature/time profiles differ by grade).

Pros and Cons

|

Pros |

Cons |

|

Very high heat resistance and high continuous service temperatures (parts are usable at temperatures where commodity plastics fail). |

Requires specialized equipment: very high nozzle temps, heated bed, and preferably an actively heated chamber — not a material for hobby desktop printers without upgrades. |

|

Excellent chemical resistance and good tribological/wear properties, suitable for harsh environments and moving parts. |

More expensive raw material and filament cost than typical engineering plastics (PLA/ABS/PC) and even than PEEK in some grades. |

|

Tunable grades allow balancing processability (printing ease) vs final performance. Some PEKK grades print with less warpage than PEEK because of slower crystallization or optimized copolymer ratios. |

Printing complexity: dimensional control, warpage, and finish depend on careful thermal management and often require annealing — adds process steps. |

Applications

• Aerospace: interior components, brackets, tooling and parts where flame/thermal performance and low weight are critical. Some PEKK grades meet aerospace interior FST (flame, smoke, toxicity) standards.

• Automotive & motorsports: under-hood components, housings and parts exposed to fuel/chemicals and high temperatures.

• Industrial tooling / end-use: durable jigs, fixtures, and small production runs where high thermal/chemical resistance is required.

• Electronics / electrical: insulating components that must tolerate elevated temperatures and chemicals.

• Medical & dental (select grades): some PAEKs are used for medical devices; PEKK has shown promise, but medical use requires certified, biocompatible grades and regulatory clearance.

PEKK vs PEEK

|

Property |

PEKK |

PEEK |

|

Typical Tg |

~160–165 °C |

~140–145 °C |

|

Typical melt/print temp |

~330–360 °C |

~330–345 °C |

|

Printability (FFF/FDM) |

Easier to tune (copolymer grades) but still requires high-temp setup |

Challenging and needs strict thermal control |

|

Thermal / oxidative performance |

Excellent, often better oxidative/flame resistance |

Excellent, slightly behind PEKK on some flame/oxidation metrics |

|

Mechanical strength |

Very high (grade dependent) |

Very high (often slightly higher baseline tensile in some grades) |

|

Cost & availability |

Premium, fewer filament grades |

Premium, more common in industry |

|

Typical pick when… |

You need better flame/oxidation resistance or easier AM tuning |

You need proven baseline mechanical performance and long track record |

FAQs

Q: Can I print PEKK on a normal desktop printer?

A: In general, no. PEKK typically needs an all-metal hotend capable of 330–370 °C, a heated build plate, and an enclosed, preferably actively heated chamber. Some industrial desktop printers marketed for high-performance polymers can handle it, but stock hobby printers usually cannot.

Q: Does PEKK emit toxic fumes while printing?

A: Compared with some plastics, PEKK is reported to emit fewer acutely toxic fumes; however, any high-temperature polymer can release VOCs and particulates. Use proper ventilation and HEPA/activated carbon filtration for safety, and follow vendor safety data sheets (SDS).

Q: Is PEKK stronger than PEEK?

A: “Stronger” depends on which metric and which grade you compare. PEEK sometimes shows higher tensile strength for some grades, while PEKK can have advantages in thermal/oxidative resistance and processability. Consult datasheets for specific grades.

Q: Do PEKK parts require annealing?

A: Many PEKK prints benefit from controlled annealing to improve crystallinity, dimensional stability and mechanical properties. Annealing profiles depend on grade and part geometry; follow the filament/grade manufacturer’s recommended procedure.

Q: What industries use PEKK most?

A: Aerospace, defense, demanding industrial tooling, some automotive and specialized electronics, and selected medical/dental applications when certified grades are used.