Banner Image Courtesy of Overture 3D

What Is Nylon Filament?

Nylon filament (polyamide) is a family of engineered thermoplastics widely used in FDM 3D printing for parts that need toughness, abrasion resistance, and some flexibility. Common industrial varieties include Nylon 6, Nylon 6/6, and Nylon 12, each with slightly different strength, moisture sensitivity, and thermal behavior. Nylon can be supplied as pure polyamide, or modified blends (glass- or carbon-filled, or copolymers) to improve stiffness, reduce warping, or add dimensional stability.

Key Material Properties

• Toughness & Impact Resistance: Nylon absorbs energy and resists cracking under shock, making it ideal for functional parts, gears, and hinges.

• Flexibility/Elongation: Nylon has higher elongation at break than PLA or ABS, so that it can flex instead of snap.

• Abrasion Resistance: Excellent sliding-wear performance — suitable for bushings, bearings, and wear surfaces.

• Chemical Resistance: Good resistance to oils, greases, and many solvents (varies with grade).

• Low-Friction Options: Filled grades (e.g., nylon + PTFE or graphite) offer lower friction further.

• Hygroscopic: Nylon readily absorbs moisture from the air; wet filament prints poorly (brittle strands, bubbling, poor layer adhesion).

• Thermal Behavior: Higher melt and extrusion temperatures than PLA; moderate to high heat deflection temperature depending on grade.

• Dimensional Stability: Prone to warping and shrinkage if not printed with appropriate settings and environment — filled or copolymer grades reduce this issue.

Pros and Cons of 3D Printing Nylon Filament

|

Pros |

Cons |

|

Excellent toughness and impact resistance |

Highly hygroscopic — requires drying and dry storage |

|

Good abrasion and wear resistance |

More challenging to print (warping, adhesion) |

|

Flexible—good for snap-fits and hinges |

Requires higher nozzle temps (abrasive-filled grades can wear brass nozzles) |

|

Chemical/oil resistance for functional parts |

Often needs an enclosure and well-leveled bed |

|

Available in reinforced/filled grades (carbon, glass) for added stiffness |

Can be less dimensionally accurate than stiff engineering plastics if not controlled |

|

Can be post-processed (annealed, smoothed with heat) |

More expensive than PLA/PETG |

Recommended Printer Settings

|

Setting |

Recommended range |

Notes |

|

Nozzle temperature |

240–270 °C |

Filled nylons may require higher temps; use hardened steel nozzle for abrasives. |

|

Bed temperature |

60–90 °C |

Helps adhesion; use PEI, garolite, or glue stick on glass. |

|

Print surface |

PEI, garolite, or nylon-specific adhesives |

PVA-based adhesives and PVA supports are not ideal; try a thin glue stick layer or tacky build surface. |

|

Print speed |

20–50 mm/s |

Slower speeds improve layer bonding and reduce stringing. |

|

Layer height |

0.1–0.3 mm |

Lower layers for higher detail; thicker for stronger parts. |

|

Cooling fan |

Off or very low |

Minimal cooling avoids layer delamination; small parts may tolerate slight fan. |

|

Enclosure |

Recommended |

Keeps ambient temperature stable, reduces warping and delamination. |

|

Retraction |

Conservative |

Reduce retraction to minimize stringing and filament grinding. |

|

Drying |

60–80 °C for 4–12 hours (timing depends on filament) |

Use filament dryer or oven; store in sealed container with desiccant. |

|

Nozzle type |

Hardened steel for filled nylons |

Carbon/glass-filled nylons are abrasive and wear brass nozzles quickly. |

Top Applications for Nylon 3D Prints

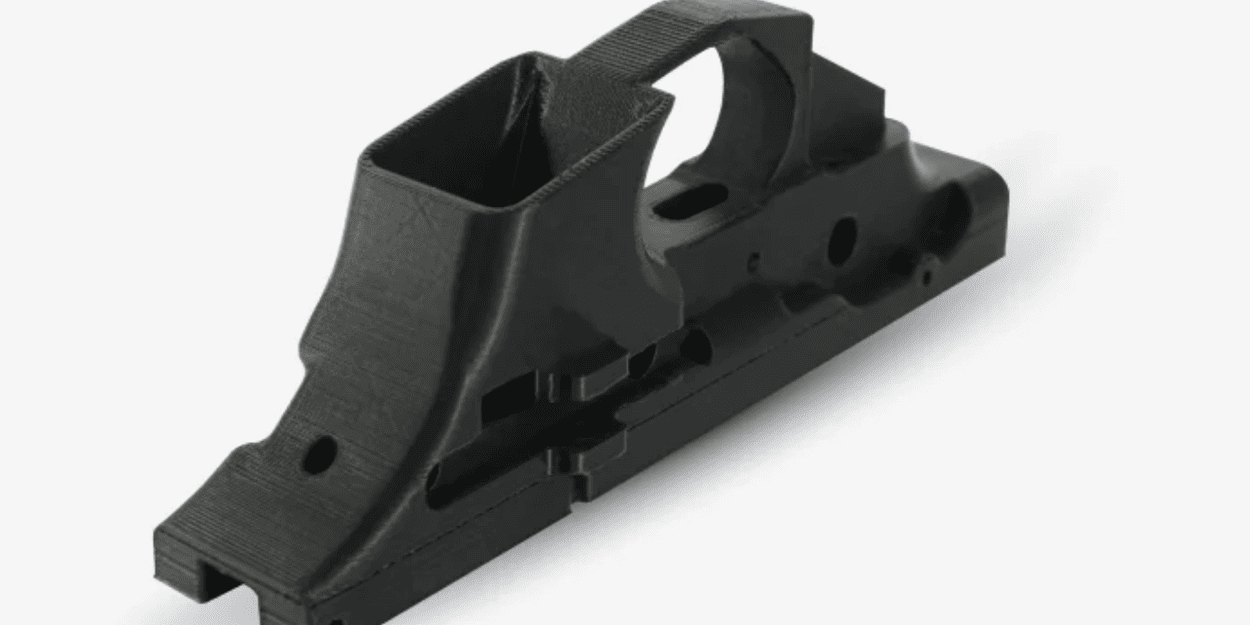

Functional Prototypes and End-Use Parts

Gears, cams, linkages, and housings that need toughness and fatigue resistance.

Mechanical Components

Bushings, bearings, straps, clips, and fasteners that experience friction and wear.

Tools and Jigs

Custom fixtures, hand tools, and manufacturing aids that must survive knocks and repeated use.

Automotive & Machinery Parts

Non-structural brackets, cable carriers, and components exposed to oil and abrasion.

Consumer Products

Snap-fit enclosures, wearable components, and flexible connectors.

Sporting Goods & Outdoor Parts

Lightweight, impact-resistant parts for drones, bicycles, and accessories (with UV-stable grade selection).

Specialty Filled Parts

Carbon- or glass-filled nylon for stiffer, high-strength parts in aerospace and industrial uses.

Try Hi3DP FDM 3D Printing Service

Looking to skip the calibration and dial-in work?

Here’s why thousands of customers trust Hi3DP:

Instant Quotes & Rapid Turnaround: Upload your STL, choose PETG, and get pricing within minutes—shipped in as little as 2 business days.

Quality Assurance: Parts undergo dimensional inspection and strength testing to meet your specifications.

Custom Finishes & Assembly: Post-processing options include sanding, painting, and chemical smoothing. Assembly and kitting services are available for multi-part projects.

Global Shipping & Support: Whether you’re in North America, Europe, or Asia, we deliver reliable quality worldwide.

FAQs

Q: Do I need a special nozzle to print nylon?

A: For pure (unfilled) nylon, a standard brass nozzle works. For carbon- or glass-filled nylons, use a hardened steel or ruby-tipped nozzle — abrasive fillers quickly wear brass.

Q: How do I stop nylon from absorbing moisture?

A: Store nylon in airtight containers with desiccant or vacuum-seal it. Before printing, dry filament in a filament dryer or convection oven at ~60–80 °C (check manufacturer guidance) for several hours.

Q: Does nylon warp a lot?

A: Compared to PLA, it warps more, yes. Use an enclosure, a heated bed, good adhesion (PEI, garolite, glue), and brims/rafts to reduce warping.

Q: Which nylon grade should I choose?

A: For general strength and flexibility, Nylon 6/6 or Nylon 6 is common. Nylon 12 is less hygroscopic and has lower shrinkage (better for dimensional parts). Filled variants boost stiffness and reduce thermal shrinkage.

Q: How to post-process nylon?

A: Nylon sands and files well after annealing; solvents are limited. Heat-set inserts work well for threads. For smoother surfaces, light tumble-polishing or vapor smoothing with specialized chemicals (used carefully) can help.