Key Cost Drivers in 3D Printing

Several factors influence the cost of 3D printing, and knowing them helps you get accurate quotes and avoid surprises.

Material Selection & Pricing

Polymers vs. Resins vs. Metals: Standard filaments like PLA or ABS cost $20–$50 per kilogram, while engineering plastics (Nylon, PETG) run $50–$100/kg. Resins start around $80/L, and specialty metal powders can exceed $500/kg.

Support Structures: Some processes (e.g., SLA) consume extra resin or powder to build supports, adding 10–30% more material usage.

Machine Hour & Technology Fees

Printer Type: Entry‑level FDM printers charge $10–$25/hr of machine time; industrial SLS or Metal AM machines can be $75–$150/hr. Complex machines with high-temperature chambers or multi‑laser setups drive the rate higher.

Maintenance & Setup: Automated bed leveling or powder handling systems reduce labor, but higher throughput systems often carry premium overhead costs.

Geometry, Volume & Layer Height

Build Volume: Large parts occupy more of the build chamber and can force longer cycles or require multiple runs.

Layer Height & Detail: Fine resolutions (25–50 microns) take 2–5× longer than coarse settings (100–300 microns), directly impacting time‑based rates.

Infill & Shell Thickness: Denser infill for structural parts increases material and print time.

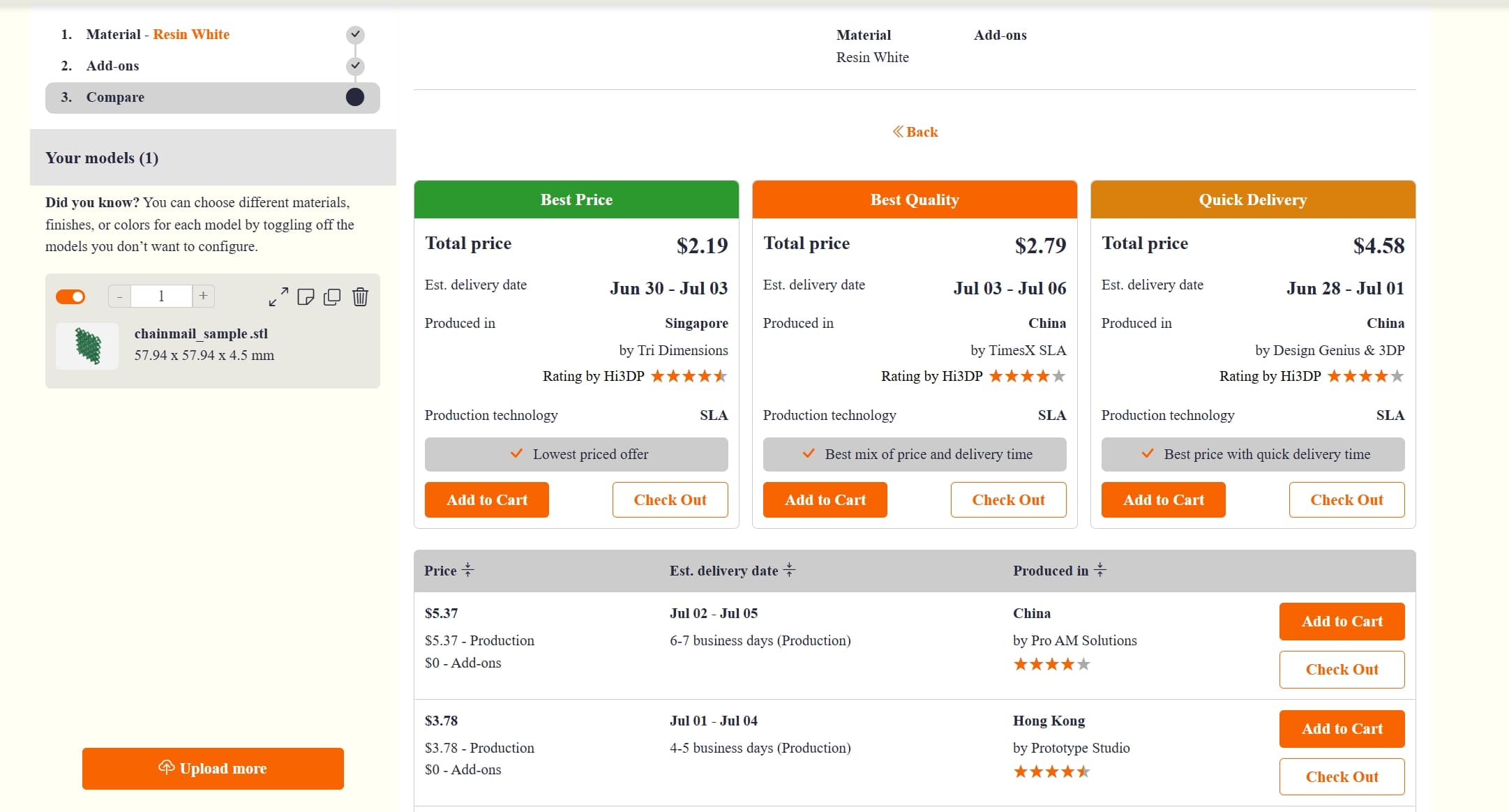

A 57.94 × 57.94 × 4.5 mm chainmail sample uses Hi3DP’s SLA 3D printing services, starting at just $2.19:

Image Courtesy of Hi3DP

See How Much Does 3D Printing Cost at Hi3DP >>

Pricing Models Explained

|

Model |

How It Works |

Best For |

|

Per‑Gram |

Charged by material used (weight after support removal) |

Small parts, simple geometries |

|

Per‑Hour |

Charged by machine run time (includes setup) |

Complex prints, fine detail |

|

Per‑Part |

Flat rate per geometry (often includes trimming) |

Batch orders, repetitive runs |

|

Combined Rates |

Mix of per‑gram + per‑hour + fixed fees |

Balanced for prototypes |

Per‑Gram vs. Per‑Hour Quotes: If your part is small but highly detailed, a per‑hour model might be more cost-effective than paying for unused builds.

Setup, Minimums & Batch Pricing: Some suppliers impose a minimum fee (e.g., $50) or offer discounted per‑part rates on batches of 10+.

Common Hidden Fees: Beware shipping (especially metal parts), customs duties, extended post‑processing (polishing, plating), and rush service surcharges.

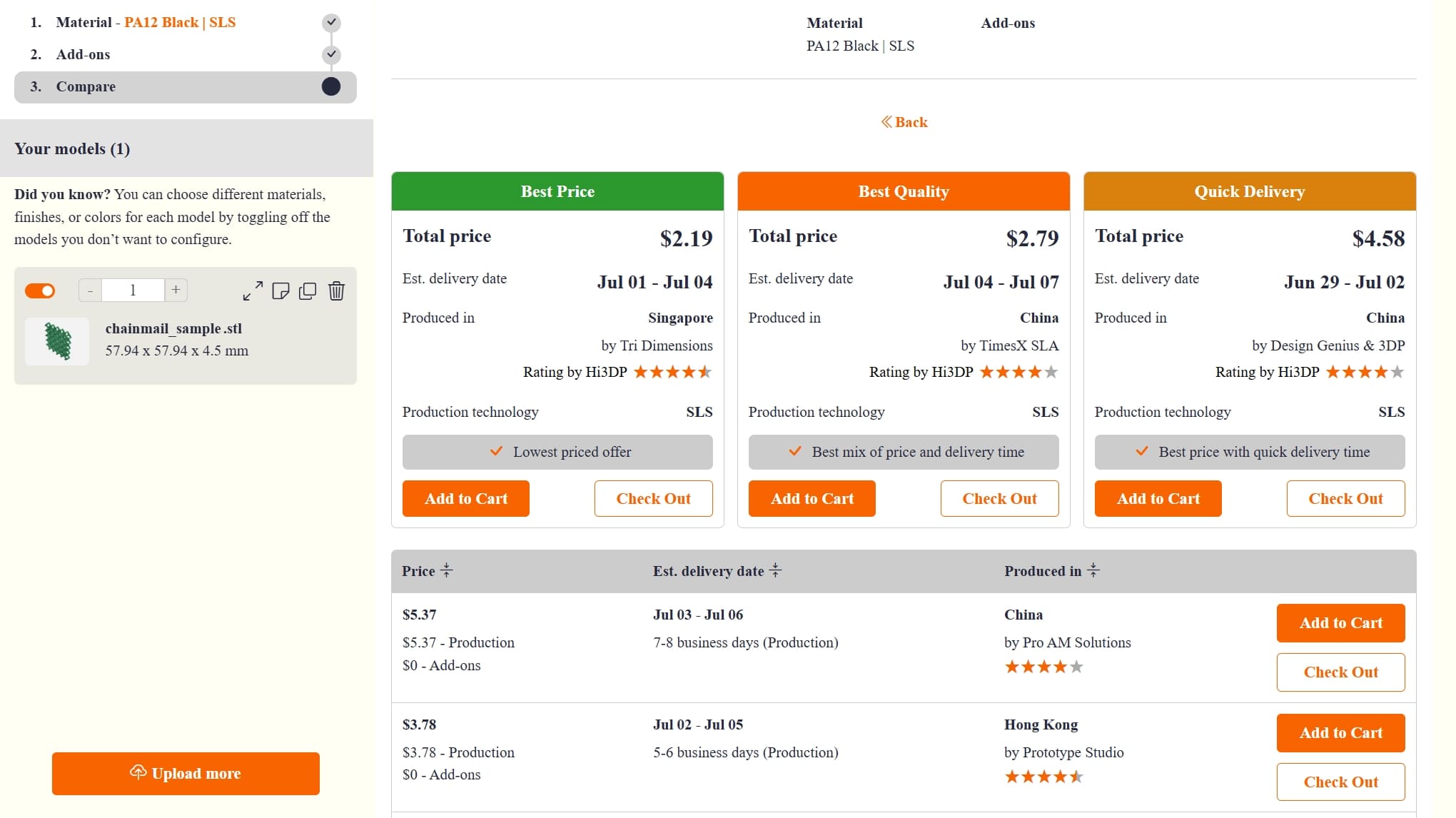

A 57.94 × 57.94 × 4.5 mm chainmail sample uses Hi3DP’s SLS 3D printing services, starting at just $2.19:

Image Courtesy of Hi3DP

See How Much Does 3D Printing Cost at Hi3DP >>

Cost Comparison of Major Processes

|

Process |

Material Cost |

Machine Rate (hr) |

Resolution |

Typical Use Cases |

|

FDM |

$25–$70/kg |

$15–$30 |

100–300 μm |

Form & fit prototypes |

|

SLA (Resin) |

$80–$150/L |

$35–$60 |

25–100 μm |

High‑detail models |

|

SLS (Nylon) |

$60–$120/kg |

$50–$75 |

80–150 μm |

Functional parts, small batches |

|

MJF (Nylon) |

$65–$130/kg |

$60–$90 |

80–120 μm |

Durable, isotropic parts |

|

SLM (Metal) |

$300–$600/kg |

$100–$180 |

20–50 μm |

Aerospace, medical implants |

*Material Cost is the raw feedstock price. Final per‑gram rates may include waste and support material.

*Machine Rate covers electricity, depreciation, and base labor.

*Resolution reflects typical layer thickness.

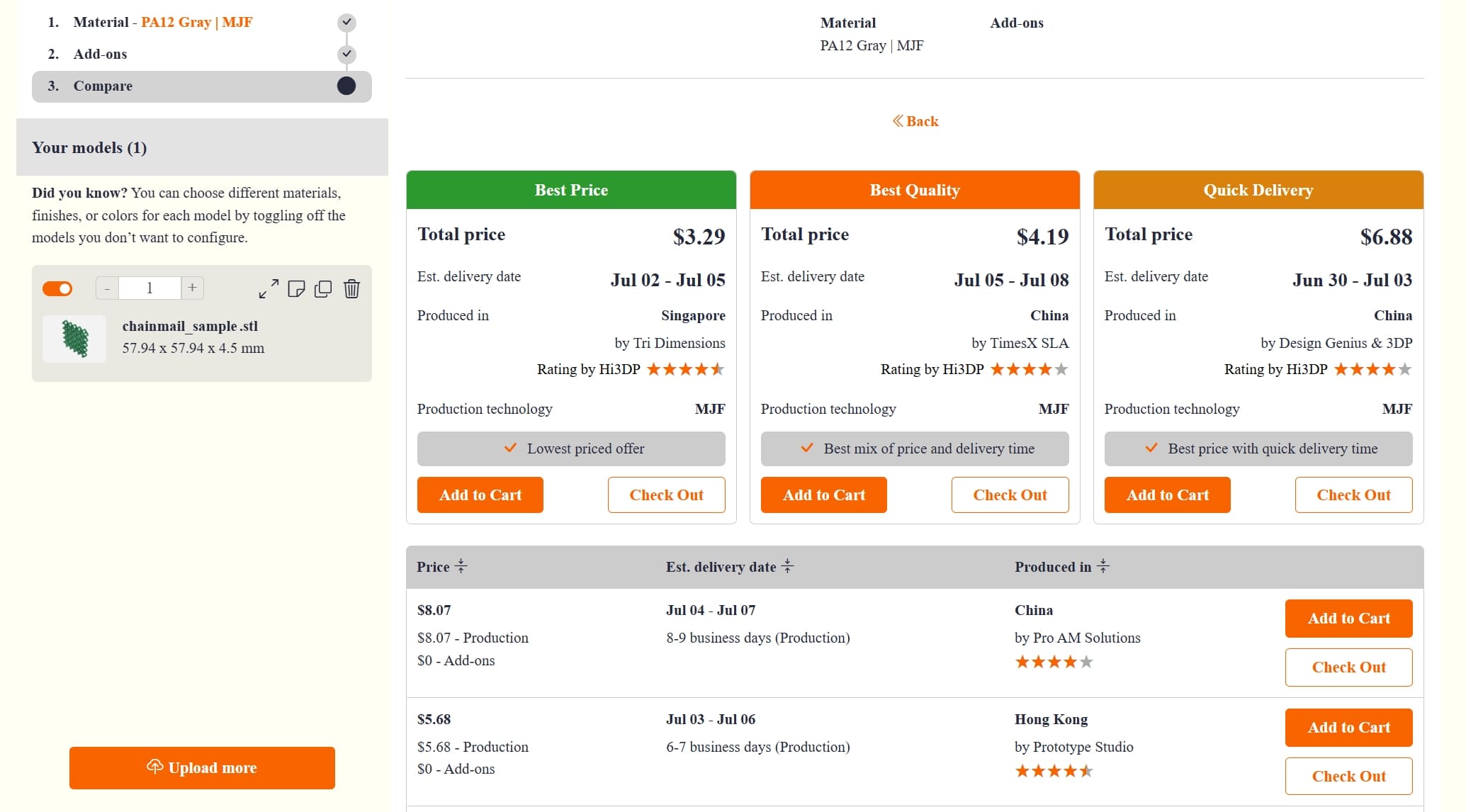

A 57.94 × 57.94 × 4.5 mm chainmail sample uses Hi3DP’s MJF 3D printing services, starting at just $3.29:

Image Courtesy of Hi3DP

See How Much Does 3D Printing Cost at Hi3DP >>

Matching Process to Your Project Needs

Choosing the right 3D printing service at Hi3DP depends on four questions:

Functional vs. Aesthetic Goals

Visual Proof-of-Concept: SLA or SLS prototypes deliver form and surface finish.

Mechanical Performance: SLS/MJF Nylon or SLM Metal offers superior strength and thermal resistance.

Tolerance, Strength & Material Requirements

Tight tolerances (<±0.1 mm) and fine details call for SLA or DLP.

Flexible or chemical‑resistant parts may require specialized resins or Nylon powders.

Lead Time, Volume & Budget Constraints

Low‑volume, quick‑turn prototypes: SLA (24–48 hr turnaround).

Larger runs of identical parts: MJF (higher throughput, lower per‑part cost).

How to Vet Suppliers & Request Quotes

Sample Parts: Always request a small test print to verify surface finish and dimensional accuracy.

Certifications: Look for ISO 9001 and NADCAP accreditation for critical industries.

Multiple Quotes: Compare at least three suppliers on total landed cost, including shipping and post‑processing.

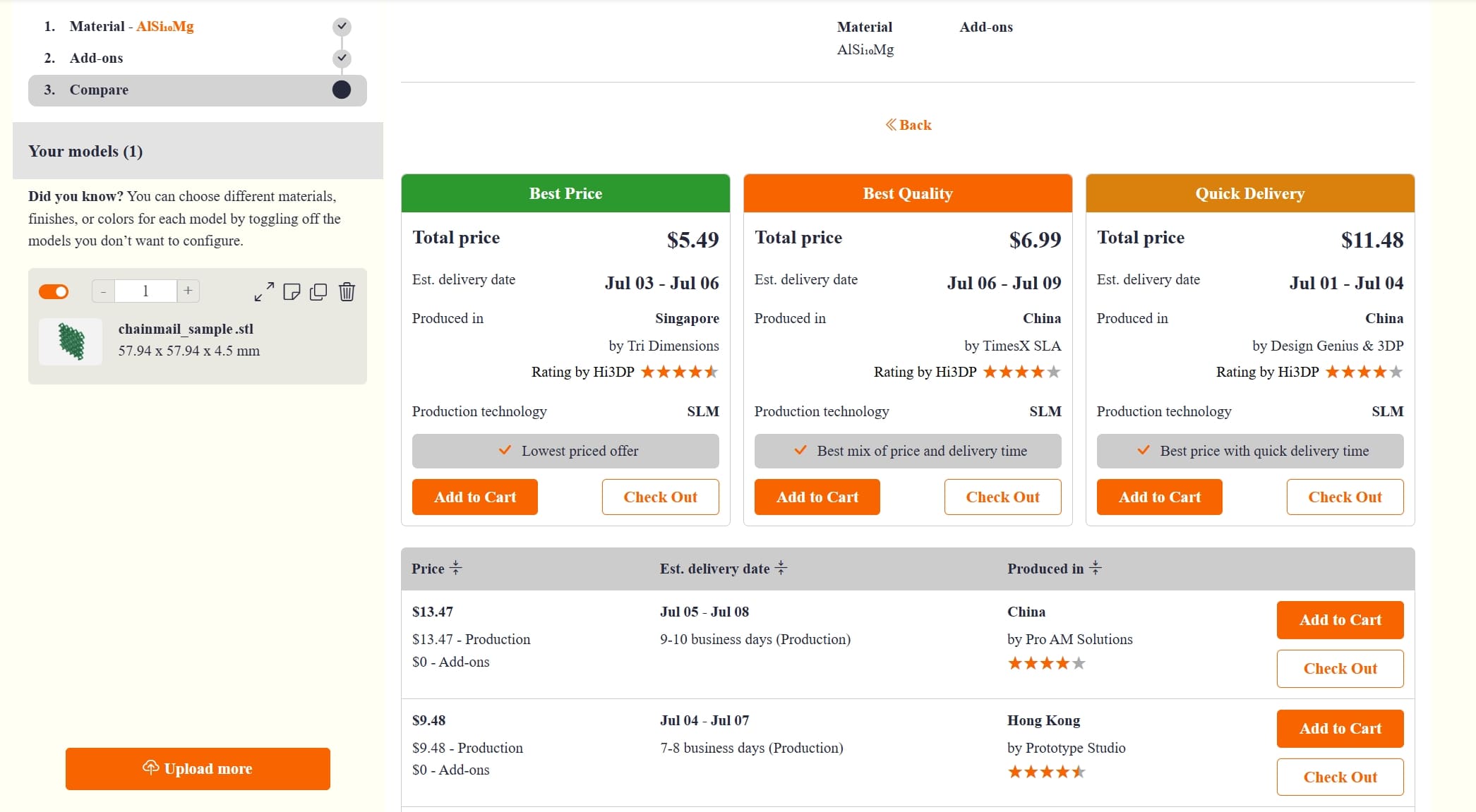

A 57.94 × 57.94 × 4.5 mm chainmail sample uses Hi3DP’s SLM 3D printing services, starting at just $5.49:

Image Courtesy of Hi3DP

See How Much Does 3D Printing Cost at Hi3DP >>

FAQs

Q: Can I get bulk discounts on 3D printing services?

A: Yes—ordering 20+ identical SLS or MJF parts can reduce per‑part rates. Contact us at hey@hi3dp.com, let's help you find the possible suppliers.

Q: Are there cost differences between resin brands?

A: Premium resins (engineering, clear, or biocompatible) cost 20–50% more than standard photopolymer.

Q: What hidden fees should I watch for?

A: Post‑processing (support removal, polishing), expedited shipping, customs duties on metal parts, and rush‑order surcharges.

Q: How do I get an accurate quote?

A: Upload your STL/STEP file to Hi3DP’s quoting tool, specify material and finish requirements, and receive instant pricing.