For each resin family, it explains their strength, detail resolution, heat resistance, transparency, typical applications, and practical considerations. Hi3DP delivers a decision chart that helps hobbyists, designers, and engineers quickly match project requirements (e.g., visual quality, mechanical performance, thermal tolerance, or optical clarity) to the best resin choice for prototyping or end‑use parts.

Standard Resins (White / Black)

Standard resins are the workhorses of SLA printing. They produce high-stiffness, high-resolution parts with a smooth, injection-molding-like finish. In Hi3DP’s lineup, Standard Resin White and Standard Resin Black fit this category. These resins are typically affordable and easy to print, making them ideal for concept models, concept art, and general-purpose prototypes.

Pros: Standard resins have very fine detail and smooth surfaces (especially in grey or white versions). White standard resin parts can be painted or plated easily, while grey or black versions may hide layer lines better. They are “visual” resins: great for display models, consumer-electronics prototypes, art models, or test fits where aesthetics matter.

Cons: These resins tend to be brittle and have low impact strength, so that they can shatter under load. They also have low heat resistance (low Heat Deflection Temperature). Standard parts should be handled gently or reinforced if used in functional testing.

Colors: Hi3DP’s standard offerings include White and Black. Hi3DP’s Standard White resin is formulated for a smooth finish and good toughness. Standard Black is similar but optimized for durability and a sleek black appearance (the product with thin wall thickness may have a translucent black appearance).

Use Cases: Good for quick prototypes, consumer-product concepts, artistic sculptures, props, and any visual models where surface quality and detail are key. They are often the most affordable option and are commonly used for concept modeling and artistic projects.

Image Courtesy of Hi3DP

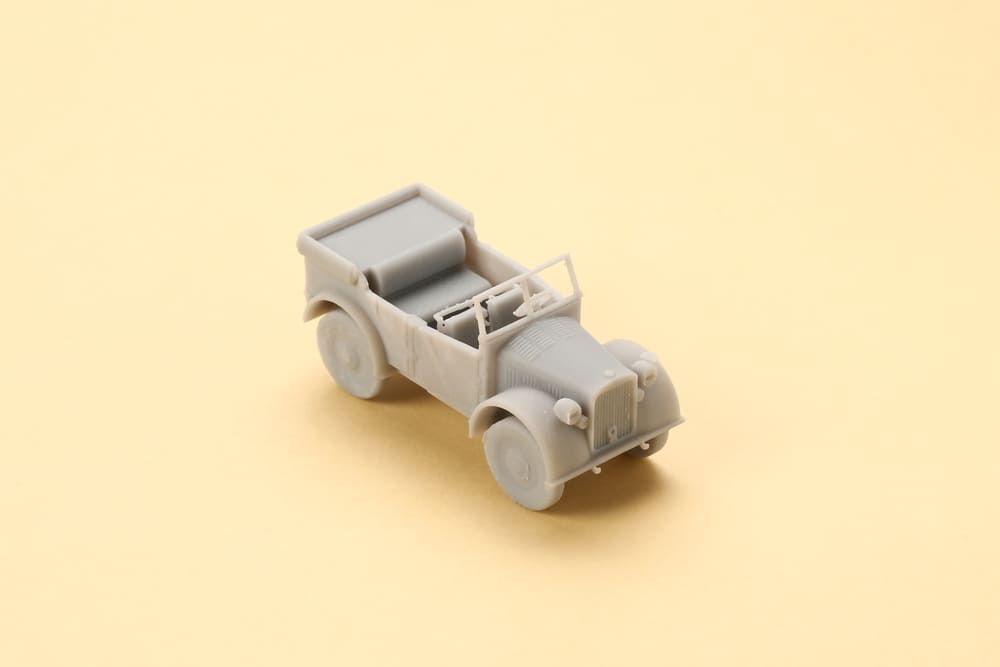

High-Detail Resins (Gray / White)

High-detail resins take visual quality a step further. These resins (available in Gray and White) are engineered for ultra-fine resolution. Hi3DP’s High-Detail Resin Gray and High-Detail Resin White can print extremely small geometries (often with layer heights as low as 25–50 microns) to capture intricate designs. The result is a matte-finish part with sharp detail, which is ideal for miniatures, fine sculptures, jewelry patterns, and precision medical models.

Image Courtesy of Hi3DP

Pros: These resins shine in producing “ultra-fine resolution” models. Small text, textured surfaces, and delicate overhangs come out cleanly. The surface is very smooth yet matte, which also eases post-processing like painting or electroplating.

Cons: Like standard resin, high-detail formulations are relatively brittle and not meant for heavy loads. They also usually require longer print times (thinner layers) to achieve their detail.

Colors: High-Detail Resin Gray typically offers the best surface fidelity, whereas High-Detail Resin White is used when you want to paint or plate the part (the white base can improve the brightness of paint or plating). Both are opaque.

Use Cases: Miniatures, figurines, jewelry prototypes, intricate consumer products, and any application where visual precision is crucial. For example, medical device models or complex aesthetic parts for architecture or entertainment often use high-detail resins.

Image Courtesy of Hi3DP

Tough Resin (White)

Tough resins are formulated for strength and durability, trading some detail for mechanical performance. Parts printed in tough resin are sturdy, shatter-resistant prototypes – imagine durable snap-fit enclosures or outdoor equipment parts.

Image Courtesy of Hi3DP

Pros: High stiffness and good resistance to repeated loading. Tough resin parts can withstand bending and snapping better than standard parts. It also has moderate heat resistance (better than standard resin) and a smooth paintable finish.

Cons: Tough resin still isn’t as impact-resistant as true flexible materials – walls thinner than ~1 mm can be risky. Also, it remains relatively brittle compared to plastics like ABS or PLA when stressed suddenly. It is not formulated for very high heat (HDT is still low).

Use Cases: Functional prototypes and mechanical parts. Think snap-fit housings, brackets, functional tools, rugged prototypes, or any piece that needs to endure handling and fitting.

Ultra-Tough Resins (Yellow / Blue)

Ultra-Tough resins push durability even further. Hi3DP offers Ultra Tough Resin Yellow and Ultra Tough Resin Blue. These materials have exceptional mechanical properties and toughness. Ultra-tough parts can handle more stress and impact than regular tough resins.

Image Courtesy of Hi3DP

Pros: These resins still have a relatively smooth surface finish but yield parts that can withstand heavy use and rough handling. They have high tensile strength and improved heat deflection (Ultra Tough Blue has HDT ≈90°C, much higher than standard resin). The Ultra Tough Yellow is bright and easy to see, while the Blue offers outstanding impact resistance (noted for automotive or industrial testing).

Cons: Ultra-tough parts tend to show layer lines more because of their dark color (for the blue) or bright color (for the yellow). They are also still rigid (not soft/rubber-like) and can become brittle over long UV exposure, so post-process UV-blocking finishes are recommended for outdoor use.

Use Cases: Work-like prototypes and functional tests. Examples include working snap-fit assemblies, rugged enclosures, automotive or aerospace component prototypes, and sports or industrial equipment parts. The Ultra Tough line is chosen when you need a part that behaves more like the final end-use plastic (e.g., polypropylene or polycarbonate).

Image Courtesy of Hi3DP

High-Temperature Resin (Red)

High-temperature resistant resins are engineered to resist heat. After full post-curing, these parts have the highest heat deflection temperatures (HDT) of any SLA material. For example, Formlabs’ High Temp Resin reaches about 238 °C (HDT) after thermal post-cure. Hi3DP’s version also has high tensile strength and a translucent red color for heat-resistant prototypes.

Pro: Exceptional thermal stability. These resins maintain dimensional accuracy and strength at elevated temperatures (often >200 °C). They also provide a smooth surface and can be translucent. High-temp parts can be used in tooling and fixtures.

Cons: Like standard resins, high-temp resin parts are still brittle and low in elongation, so they crack under sharp impacts. They also require careful post-curing (often dual-step thermal cure) to reach maximum heat tolerance.

Use Cases: Any application needing heat resistance, e.g., molds, tooling, hot-air or hot-water fluid channels, engine components, or light fixtures.

Image Courtesy of Hi3DP

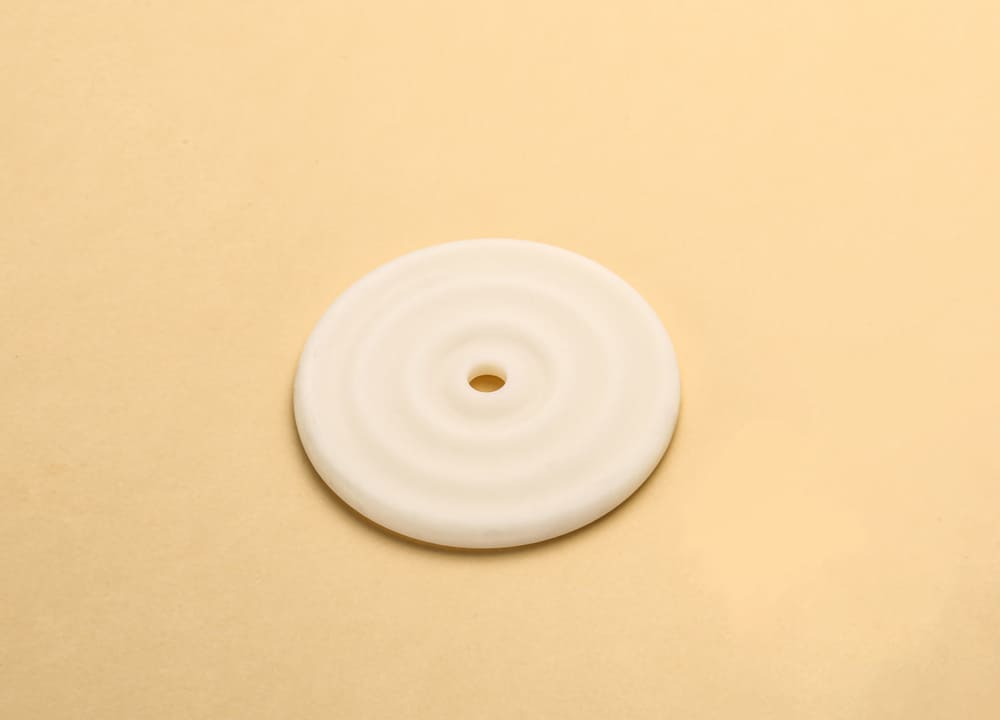

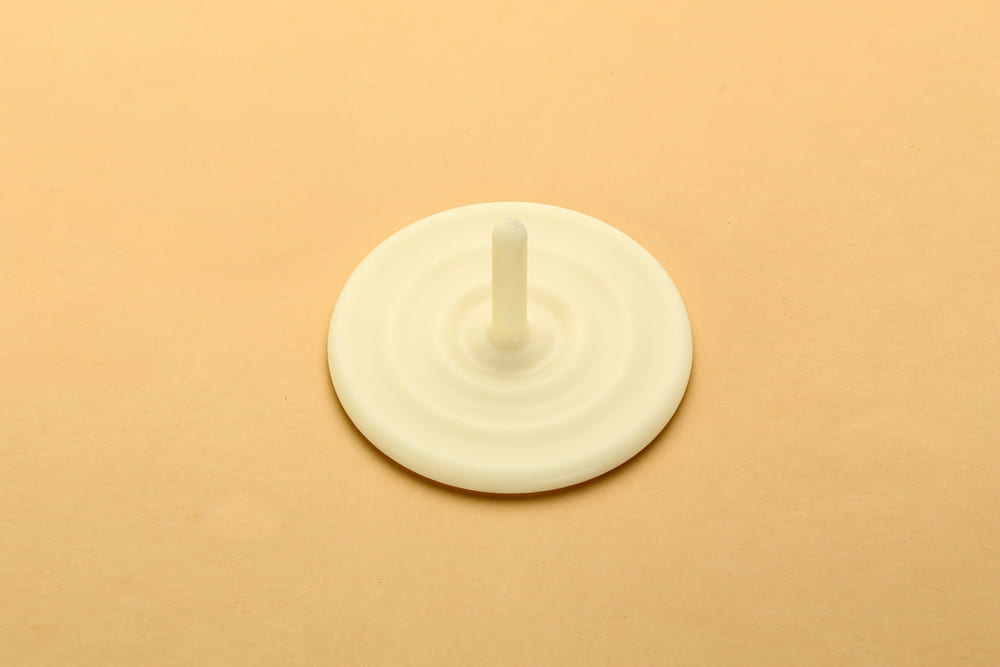

Premium Clear Resin

Premium Clear resin (often just “clear” SLA resin) yields transparent or translucent parts. Hi3DP’s Premium Clear Resin is formulated for excellent optical clarity and a smooth finish. It cures into parts that look like see-through plastic (after polishing), enabling prototypes like light pipes, fluidic channels, or aesthetic models where transparency is needed.

Pros: Exceptional transparency. Parts start clear and can be post-processed to near-optical clarity. They showcase internal features (e.g., gears or fluid channels) and are stable even in humid conditions.

Cons: It is still a typical photopolymer, so it remains relatively brittle and UV-sensitive. Over time, it can yellow if exposed to sunlight directly. Also, thick sections may trap bubbles, so careful print orientation and supports are important.

Use Cases: Optical prototypes (lenses, light guides), demonstration models showing internal structure (pipes, electronics housing windows), or any application needing a translucent look.

Image Courtesy of Hi3DP

Choosing the Right Resin

|

Resin Type |

Strength |

Detail |

Heat Resistance |

Transparency |

Best For |

|

Standard White/Black |

Medium |

High |

Low |

Opaque |

Concept models, visual prototypes, form/fit tests |

|

High‑Detail Gray/White |

Low–Medium |

Ultra‑High |

Low |

Opaque |

Miniatures, jewelry patterns, medical models |

|

Tough White |

High |

Medium |

Medium |

Opaque |

Functional prototypes, snap‑fit parts, enclosures |

|

Ultra‑Tough Yellow/Blue |

Very High |

Medium |

Medium–High |

Opaque |

Rugged assemblies, automotive/industrial tests |

|

High‑Temp Red |

Medium |

Medium |

Very High |

Translucent red |

Mold/tooling, engine fixtures, high‑heat parts |

|

Premium Clear |

Medium |

High |

Low–Medium |

Transparent |

Light guides, fluidics, display windows |

FAQs

Q: What types of resins are available for SLA printing, and what are their typical uses?

A: Common categories include standard (visual prototyping), engineering/tough (functional parts), high‑detail (miniatures/jewelry), high‑temp (heat‑resistant tooling), and clear (optical).

Q: Are SLA resin prints waterproof or water‑resistant?

A: SLA prints are generally water‑resistant but not completely waterproof; prolonged water immersion can lead to dimensional changes or swelling unless sealed with a coating.

Q: Can SLA printers produce strong, engineered parts suitable for functional use?

A: Standard SLA parts are often brittle, but using engineering‑grade or “tough” resins can yield ABS‑like strength.