How SLM Affects Metal Microstructure & Properties

SLM 3D printing fuses fine metal powder layer by layer with a high‑powered laser. This rapid melting and solidification cycle creates a unique microstructure:

Fine Grain Structure

High cooling rates (10³–10⁶ K/s) yield very fine grains, often finer than cast or forged parts. Finer grains typically boost yield and tensile strength.

Residual Stress & Porosity

Uneven heating can trap stresses, leading to warping or even micro‑cracks. Poorly optimized parameters can also leave microscopic pores, reducing fatigue life.

Anisotropy

Strength often varies with build orientation. Vertical (Z‑axis) properties can differ from horizontal (XY‑plane) properties due to layer interfaces.

Process Parameters

Laser power & scan speed: Higher power or slower scans improve fusion, but can overheat.

Layer thickness & hatch spacing: Thinner layers and tighter hatch increase resolution and density, but slow down builds.

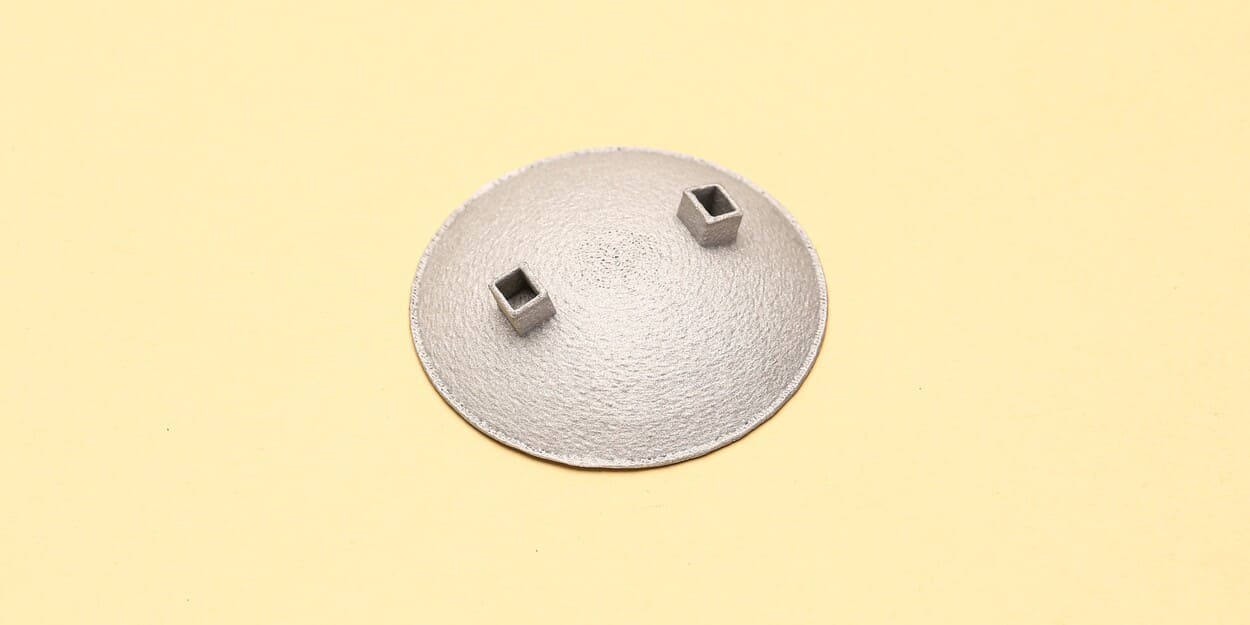

Image Courtesy of Hi3DP

Common SLM Printable Metals & Their As Printed Properties

|

Alloy |

Tensile Strength |

Yield Strength |

Elongation |

Hardness (HV) |

Density (g/cm³) |

Applications |

|

316L Stainless |

480–600 MPa |

300–450 MPa |

20–40 % |

150–200 |

8.0 |

Food equipment, tooling |

|

17‑4 PH Steel |

1000–1150 MPa |

900–1000 MPa |

8–12 % |

300–350 |

7.8 |

High‑strength parts, valves |

|

Ti‑6Al‑4V |

900–1050 MPa |

800–900 MPa |

8–12 % |

330–380 |

4.43 |

Aerospace brackets, medical implants |

|

AlSi10Mg |

300–350 MPa |

200–240 MPa |

3–6 % |

120–140 |

2.67 |

Lightweight housings, prototypes |

|

Inconel 718 |

1000–1200 MPa |

800–900 MPa |

30–45 % |

350–400 |

8.19 |

High‑temp turbine parts |

|

CoCrMo |

600–900 MPa |

400–600 MPa |

20–30 % |

250–300 |

8.3 |

Dental implants, surgical tools |

|

Maraging Steel |

1000–1200 MPa |

900–1100 MPa |

5–15 % |

500+ |

8.0 |

Tooling inserts, mold components |

Comparing SLM Printed vs. Conventionally Manufactured Metals

|

Metric |

SLM 3D Print |

Casting/Forging |

|

Tensile Strength |

Comparable or higher |

Varies; often lower |

|

Yield Strength |

Often higher |

Standard specs |

|

Elongation |

Slightly lower |

Higher ductility |

|

Surface Finish |

Rougher; requires post‑process |

Smoother from mold |

|

Complexity |

Unlimited geometry |

Limited by tooling |

|

Lead Time |

Days or hours |

Weeks or months |

Pros of SLM Metal 3D Printing:

Design freedom: Lattice, internal channels, organic shapes

Rapid iteration: Quick tweaks and reprints

On‑demand parts: No need for expensive tooling

Cons:

Surface roughness: Often needs machining or bead blasting

Equipment cost: Desktop SLM machines still represent a significant investment

Anisotropy & defects: Requires careful parameter tuning

For hobbyists, the biggest advantage of metal 3D prints is unlocking complex geometries that would be impossible with traditional CNC or casting methods.

Key Factors That Influence As Printed Strength

Powder Quality

Fresh, spherical powder with a tight size distribution reduces porosity.

Reused powder can degrade properties over multiple cycles.

Build Orientation

Vertical walls vs. horizontal planes have different layer bonding.

Angled orientations can mitigate stress concentrations.

Scan Strategy

Alternating scan vectors and chessboard patterns improve uniformity.

Optimal hatch spacing ensures proper overlap between melt tracks.

Thermal Management

Preheating the build plate minimizes residual stresses.

Controlled cooling ramps can reduce cracking in high‑alloy steels.

Post‑Processing

Stress Relief Annealing: Lowers internal stresses without drastically changing strength.

Hot Isostatic Pressing (HIP): Virtually eliminates internal porosity, boosting fatigue life.

Surface Finishing: Machining, grinding, or polishing can improve fatigue resistance and reduce stress risers.

Image Courtesy of Hi3DP

FAQs

Q: Are metal 3D prints as strong as forged parts?

A: Often, SLM printed metals match or exceed the tensile strength of forged parts, thanks to fine microstructures. However, ductility may be slightly lower without proper post‑processing.

Q: How anisotropic are SLM parts?

A: Strength can vary by 5–20 % between build directions.

Q: Does SLM's process use recycled powder?

A: Yes, but the powder should be sieved and tested. After ~10 builds, mechanical properties can degrade due to increased oxygen and particle irregularities.

Q: Do I need HIP for hobby projects?

For non-critical parts, HIP isn’t mandatory. But if you need a high-fatigue life, HIP or densification steps make a big difference.

Q: Which alloy is best for first-time users?

A: AlSi10Mg, Aluminum 6061, or 316L stainless steel are recommended for hobbyists.