Stereolithography (SLA) is one of the most popular and precise 3D printing technologies available today. Known for producing high-resolution parts with smooth surface finishes, SLA is widely used across industries ranging from medical and dental to prototyping and product design. In this article, we'll break down everything you need to know about SLA 3D printing—how it works, its benefits, limitations, and how to choose the right service provider.

What is SLA 3D Printing

SLA (Stereolithography) 3D printing is a premier resin-based fabrication process that uses a UV laser to cure liquid photopolymer, layer by layer, into solid parts. In fact, SLA was the first commercial 3D printing technology (patented in 1986) and remains a go-to method for high-detail prototypes and complex models. Often called resin 3D printing, SLA can produce extremely accurate, fine-featured parts with smooth, polymer-like surface finishes.

Today, hobbyists, engineers, and businesses alike rely on SLA 3D printing for everything from concept models to functional prototypes. The Hi3DP platform makes it easy to access SLA services: simply upload your design, choose a photopolymer resin, and get quotes from top suppliers in seconds.

Image Courtesy of Hi3DP

How Stereolithography Works

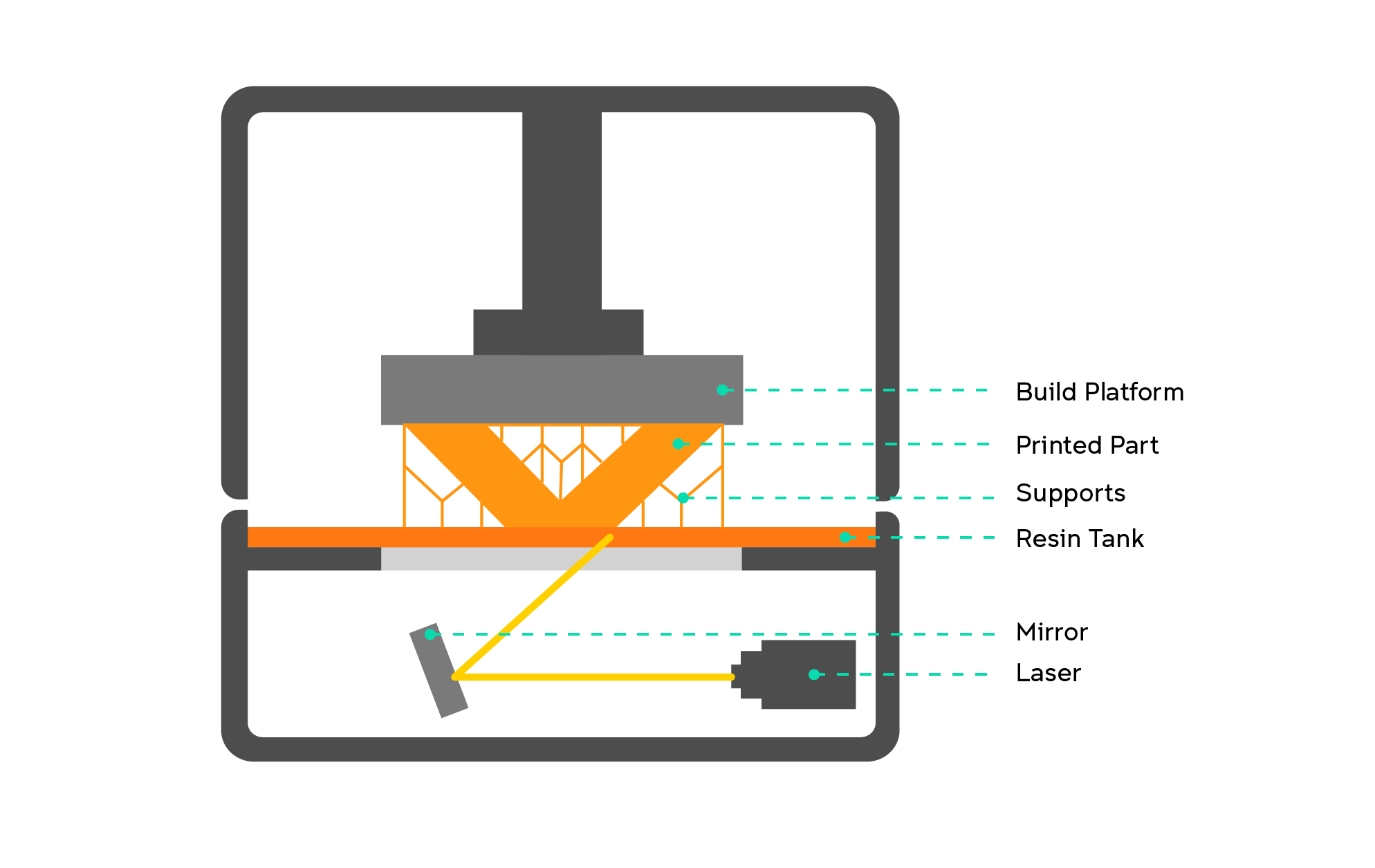

Stereolithography (SLA) works by selectively solidifying liquid resin.

First, a build platform is positioned just above the surface of a vat of liquid photopolymer. A focused UV laser then scans the surface, tracing the cross-section of the part. Wherever the laser strikes, the resin molecules undergo a photochemical reaction and solidify, bonding into the previous layer.

After each layer is cured, the platform lifts (usually by a few dozen microns), allowing fresh resin to flow under the part. The build plate then lowers again for the next layer, making it seem as if the part is “growing” upside-down out of the resin bath.

Throughout the print, the laser is guided by fast mirrors (galvanometers) to ensure each path is precise. Complex parts often require thin support structures to hold overhangs; these supports are printed along with the part and removed later.

When printing is done, the uncured resin is washed off (typically with isopropyl alcohol), and the part is post-cured under UV light to complete the polymerization. The final curing step ensures the 3D printed resin reaches its full strength and thermal stability. (Unlike FDM plastics, SLA materials are thermoset – once cured, they cannot be melted down again.)

In the end, you get a solid plastic part with exceptionally fine detail and a smooth finish.

Image Courtesy of UNSW Sydney

Resin Types for SLA 3D Printing

|

Resin Type |

Key Properties |

Common Applications |

Benefits |

|

Standard Resin |

- Smooth surface finish |

- Concept models |

Affordable, beginner-friendly, versatile for basic needs |

|

Tough & Durable |

- High impact resistance |

- Functional prototypes |

Mimics engineering plastics, withstands stress & wear |

|

Engineering Resins |

- Heat resistance (up to 200°C) |

- Automotive/aerospace parts |

Built for extreme conditions, tailored performance |

|

Castable Resins |

- Low ash residue |

- Jewelry molds |

Simplifies investment casting, no mold-making required |

|

Biocompatible Resins |

- Non-toxic post-curing |

- Surgical guides |

Medical/dental compliance, safe for human use |

Applications of SLA 3D Printing

Rapid Prototyping

SLA is perfect for creating high-fidelity prototypes of consumer products, electronics, and artwork. Because of its precision and smooth finish, design teams use SLA models to evaluate form, fit, and function before tooling. The fast printing speed also allows quick iteration during product development.

Casting and Tooling

Designers often use SLA to produce sacrificial patterns for investment casting or molds. High-detail SLA patterns are burned or dissolved to form cavities for metal casting or urethane injection molding. This is popular in jewelry (making finely detailed mold patterns) and in manufacturing custom tooling or jigs.

Dental and Medical Models

In dentistry and healthcare, SLA excels at ultra-precise, biocompatible parts. It can produce accurate dental models, crowns, bridges, and orthodontic guides based on patient scans. Surgeons also use SLA to print anatomical models and surgical guides for pre-surgical planning, as well as custom prosthetics and implants in orthopedics.

Aerospace

Aerospace engineers leverage SLA for lightweight, complex parts where precision matters. SLA parts serve as custom flight hardware, instrument mounts, or aerodynamic test models. It’s also used for making specialized jigs, fixtures, and tools for aircraft production.

Automotive

Car manufacturers and racing teams use SLA for rapid prototyping of interior components, engine parts, and custom tooling. Fine-detail SLA models can be wind-tunnel tested (e.g. scale models) and are used to create prototype dashboards, fixtures, and small functional parts.

Consumer Electronics & Product Design

For electronics and gadgets, SLA can produce enclosures, casings, or ergonomic prototypes with smooth faces and sharp lettering. Designers can validate aesthetics and ergonomics on 3D printed models before moving to final production.

Image Courtesy of Hi3DP

Advantages of SLA

High Resolution – Capable of producing fine features and complex geometries.

Smooth Surface Finish – Ideal for visual prototypes and end-use aesthetics.

Tight Tolerances – Consistent dimensional accuracy for engineering applications.

Material Versatility – Specialized resins tailored for strength, flexibility, or biocompatibility.

Limitations of SLA

Brittleness – Standard SLA resins can be more brittle than thermoplastics.

Post-Processing – Requires support removal and additional UV curing.

Limited Size – Build volumes are generally smaller than other technologies like FDM or SLS.

UV Sensitivity – Parts may degrade with prolonged exposure to sunlight unless properly finished.

Cost and Lead Time

Cost

SLA printing tends to be more expensive per part than basic FDM, mainly due to resin and machine costs. Photopolymer resins can cost from about $50 up to $500 or more per liter, depending on the material’s specialty. The final price of your part will depend on its volume (resin used), complexity, and finishing steps.

Always compare quotes from multiple suppliers to ensure you’re getting a good value. Keep in mind that very small parts may incur a minimum charge, and adding optional services (like rush processing or special coatings) will increase the price.

However, the precision and quality of SLA often justify the higher cost for critical applications.

Lead Time

SLA services generally offer fast turnaround. Simple SLA jobs (small models, one or two parts) can be printed and shipped within 1–3 business days. Larger builds or high-volume batches may take longer.

When ordering, check the service’s standard lead time and whether you need expedited service. Some providers advertise “next-day SLA” for prototypes. Also factor in shipping time: Hi3DP offers both Priority (3–5 day) and Economy (9–12 day) shipping options in the U.S.. For example, you could have a prototype in hand within a week even with a moderate lead time plus shipping.

In short, plan your schedule around the quoted lead time and shipping. If a project is time-sensitive, mention it upfront. Many SLA platforms allow you to see estimated delivery dates when you get quotes. As for cost, remember that SLA might be pricier than FDM or SLS, but you’re paying for higher resolution and speed. Often the extra expense pays off by catching design issues early or avoiding expensive tooling changes later.

Image Courtesy of Hi3DP

Considerations for Choosing SLA 3D Printing Services

Technology & Materials Offered

Make sure the provider actually uses stereolithography (SLA) and offers the specific resin(s) you need. Some online platforms list multiple technologies (SLA, SLS, FDM, etc.), so be sure to filter or specify SLA. Also check the printer’s build volume and class (desktop vs. industrial). Industrial SLA machines offer larger prints and tighter tolerances.

Reputation & Quality

Choose a service with proven experience in SLA printing. Look for customer reviews or case studies. Providers with ISO certifications or quality control processes tend to deliver more consistent results. High standards mean fewer print failures. A provider’s knowledge of SLA design rules (like optimal wall thickness and support orientation) can save you time and material.

Pricing & Transparency

Obtain detailed quotes that break down cost by material, volume, and finishing. Beware of hidden fees. Some companies have obvious “base price” plus per-gram resin costs. Others bundle services. Hi3DP’s instant-quote system helps here by letting you compare complete pricing from multiple suppliers simultaneously, ensuring you pick the best value. Always ask if rush jobs or extra support removal will cost extra.

Additional Costs

Be aware of any extra charges for shipping, post-processing, or setup. For example, shipping fees can add 10–20% to your bill if parts are heavy or exotic. Post-processing like UV curing, sanding, or dyeing may also incur fees. Make sure your quote clarifies which services (e.g. support removal or basic polishing) are included.

Design & Post-Processing Support

Some SLA services offer design feedback or finishing options that can be extremely helpful. For instance, they might suggest adding drainage holes for resin or reinforce thin features. Others provide advanced post-processing like painting, dyeing, or plating. If you need turnkey parts, choose a provider that offers comprehensive support and finishing.

Turnaround Time

Consider the typical lead time for SLA prints. While many providers can ship in a few days, very large or high-volume jobs may take longer. Check if expedited options are available. Also plan for transportation time – some SLA resins are shipped with special handling.

Image Courtesy of Hi3DP

Why Choose Hi3DP for Custom SLA 3D Printing Services

Hi3DP is your one-stop platform for online SLA 3D printing services. Here’s why designers and engineers trust Hi3DP for our resin 3D prints:

1. Instant SLA Quotes: Simply upload your 3D model and select SLA printing; Hi3DP instantly compares offers from multiple vetted suppliers. This real-time price comparison means you’ll find the most cost-effective SLA 3D printing service without hunting through dozens of sites.

2. Extensive SLA Material Library: Whether you need a standard resin or a specialty formula, Hi3DP supports it. Our Materials page lists every resin option (from clear and black to tough, high-temp, and biocompatible resins). You can filter by properties (e.g. “smooth,” “heat-resistant”) to find the perfect SLA resin for your project.

3. Trusted Global Network: We partner only with reputable 3D printing labs that meet quality standards. Each SLA provider in our network is vetted, so your prints come from experienced professionals. We also display customer reviews and ratings to help you choose a reliable supplier.

4. User-Friendly Interface: The Hi3DP portal is designed for ease. The guided quote system walks you through selecting SLA, choosing layer thickness, and adding any post-processing. Our intelligent tools even check your file for common design issues (like non-manifold geometry) before you order. It’s built to help hobbyists and pros alike.

5. Fast, Flexible Shipping: Hi3DP offers convenient shipping options. In the U.S., choose 3–5 day Priority Plus shipping or 9–12 day Hassle-Free shipping. No matter where your suppliers are located globally, you can get your SLA parts delivered when you need them.

6. Save Time and Money: By comparing multiple SLA services at once, Hi3DP ensures you always get the best deal. Our customers often save 20–50% on SLA parts by finding the lowest bid. Plus, you skip the hassle of negotiating – just pick the quote you like and order.

Image Courtesy of Hi3DP

FAQs

Q: How accurate is SLA 3D printing?

A: SLA printers can achieve layer heights as fine as 25 microns and dimensional accuracy within ±0.1 mm.

Q: What file types do you accept for SLA printing?

A: We support .STL .STP .STEP .GLTF .OBJ .FBX .DAE .3MF .BREP .GCODE formats. If you're unsure, our team can help you convert and prepare your file.

Q: Is SLA suitable for end-use parts?

A: Yes, especially when using engineering or durable resins. It's also common for short-run production and custom-fit applications.

Q: Do you offer finishing services?

A: Yes. Hi3DP offers support removal, UV curing, sanding, polishing, painting, plating and custom surface finish on request.

Q: How much does SLA 3D printing cost?

A: The cost of SLA 3D printing depends on factors like part size, resin type, complexity, and post-processing requirements. Standard resin prints tend to be more affordable, while specialty materials and detailed finishing can increase the price.