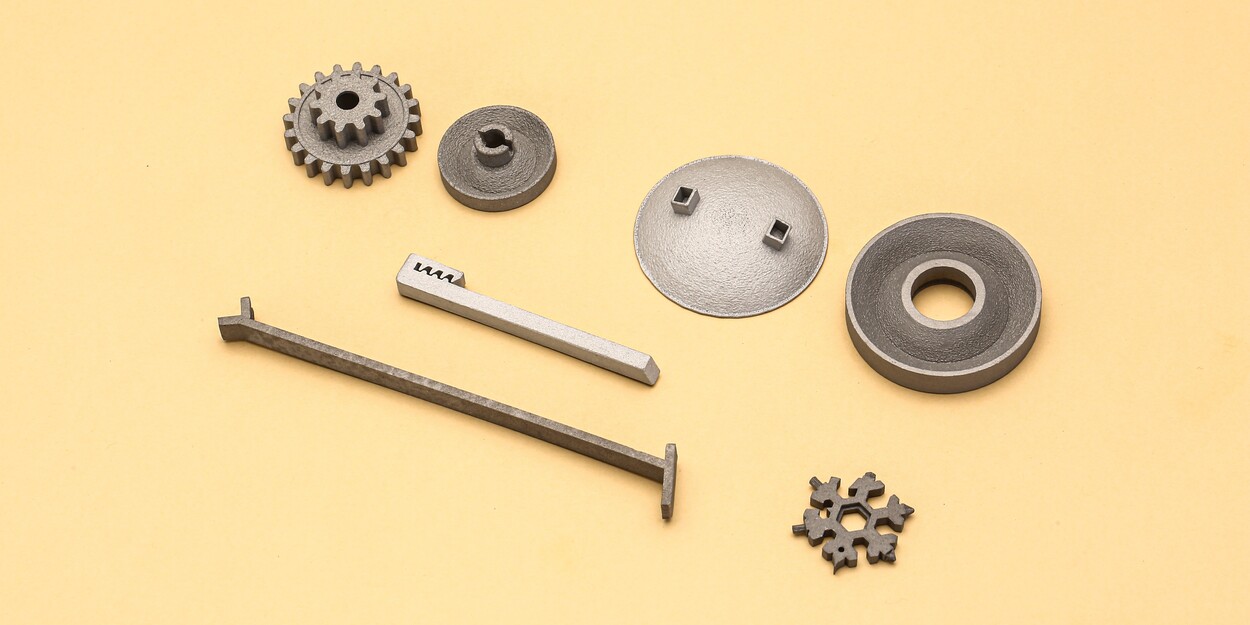

Selective Laser Melting (SLM) stands as a transformative force within metal 3D printing. This powerful AM technology enables the creation of intricate, high-strength metal components directly from digital designs. Whether you're an engineer pushing the boundaries of design, a manufacturer seeking agile production, or a designer exploring new possibilities, understanding SLM is crucial. This guide delves into every facet of SLM 3D printing, from its core principles and material options to its SLM printing services.

What is SLM 3D Printing?

Selective Laser Melting (SLM) is a laser-based powder bed fusion (PBF) additive manufacturing process used to produce fully dense, functional metal parts. Unlike processes that merely sinter particles together, SLM 3D printing uses a high-powered laser beam to completely melt fine layers of metal powder, fusing them into a solid parts.

Core Distinction: Full melting is key. SLM achieves near-net-shape parts with minimal porosity, resulting in excellent mechanical properties.

Suitable For: Complex geometries, lightweight structures (lattices, topology-optimized designs), internal channels, integrated assemblies, and high-performance components where traditional machining or casting falls short.

vs. DMLS: Often used interchangeably, Direct Metal Laser Sintering (DMLS) technically involves partial melting/sintering, while SLM implies full melting. However, in industrial practice, both terms frequently refer to fully melted processes using similar equipment. The specific machine and material parameters define the outcome more than the acronym.

Image Courtesy of Hi3DP

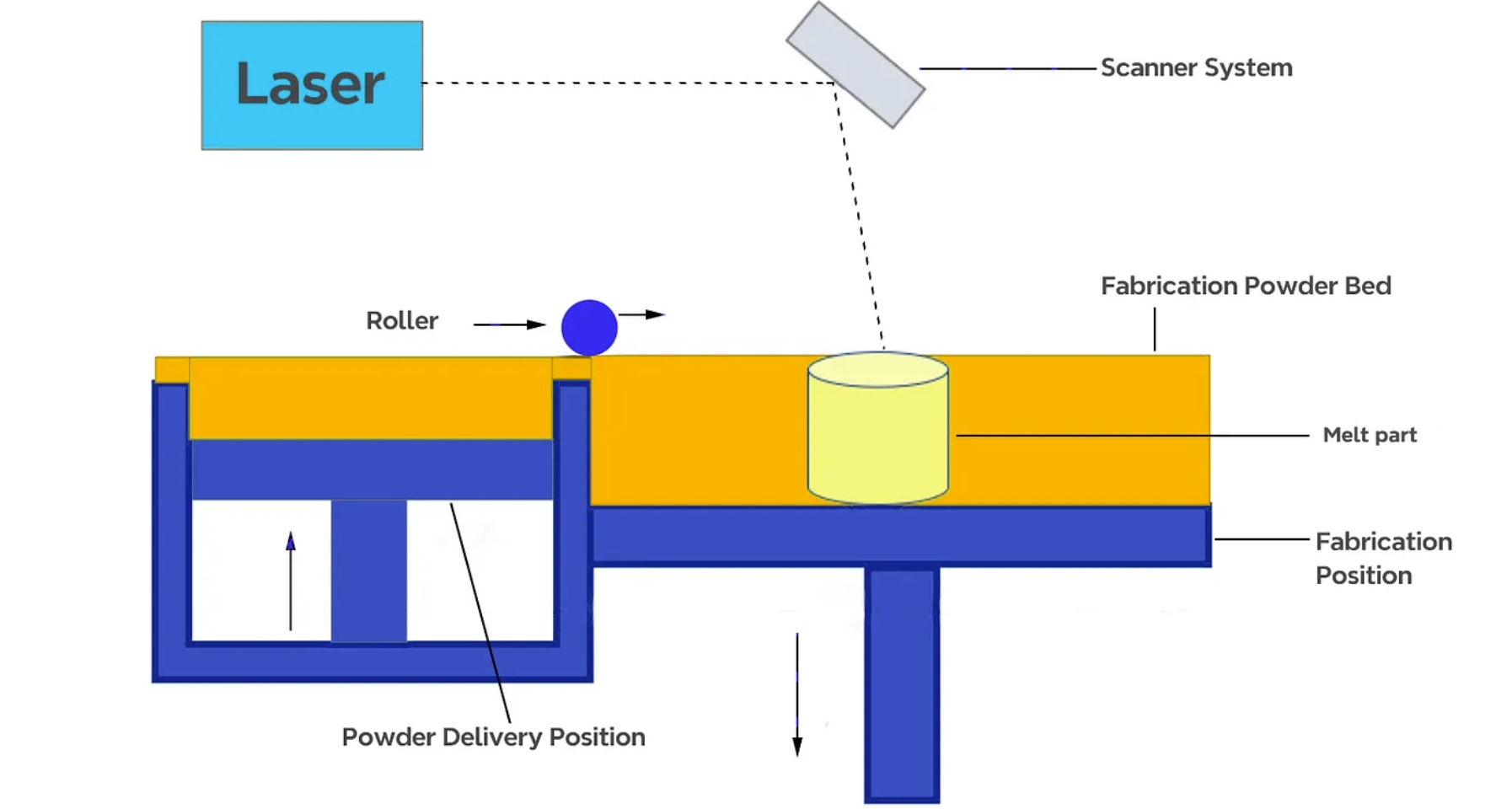

How Selective Laser Melting Works

Model Slicing: A 3D CAD model is digitally sliced into thin horizontal cross-sections (typically 20-100 microns thick).

Powder Recoating: A recoater blade or roller spreads a thin, even layer of metal powder over the build platform.

Laser Melting: A high-precision fiber laser scans the cross-section of the part onto the powder bed according to the sliced data. Where the laser hits, the metal powder particles are completely melted and fused to the layer below.

Platform Lowering: After a layer is scanned, the build platform lowers by the thickness of one layer.

Recoating & Repeating: A new layer of powder is applied, and the laser melting process repeats for the next cross-section, bonding it to the previous layer.

Build Completion: Steps 2-5 repeat until the entire part is built, encapsulated within unfused powder which provides support.

Cooling & Depowdering: After the build, the chamber cools down. The build platform is then removed, and the parts are carefully extracted from the powder cake. Excess powder is removed (depowdered), sieved, and often reused.

Post-Processing: Parts undergo various post-processing steps (see Part 6) before being ready for use.

Environment: The process occurs in a sealed chamber filled with inert gas to prevent oxidation of the reactive molten metal.

Supports: Overhanging features require thin support structures (also metal) printed simultaneously to anchor the part to the build plate and dissipate heat. These are manually removed after printing.

Image Courtesy of Medium

3D Printable Metals for SLM

|

Material |

Key Properties |

Typical Applications |

|

Ti6Al4V |

High Strength-to-Weight Ratio, Biocompatible, Corrosion Resistant |

Aerospace components, Medical Implants, Motorsport |

|

AlSi10Mg |

Lightweight, Good Strength & Stiffness, Good Thermal Conductivity |

Automotive parts, Heat Exchangers, Drones, Brackets |

|

316L Stainless |

Excellent Corrosion Resistance, Good Ductility, Biocompatible |

Marine components, Chemical processing, Medical devices |

|

17-4 PH SS |

High Strength & Hardness (after heat treat), Good Corrosion Resistance |

Aerospace fittings, Gears, Shafts, Tooling |

|

Inconel 718 |

Exceptional High-Temp Strength, Oxidation & Creep Resistance |

Turbine blades, Rocket engines, High-temp tooling |

|

H13 Tool Steel |

High Hardness & Wear Resistance, Good Thermal Fatigue Resistance |

Injection Molds, Die Casting Cores, Hot Stamping Tools |

|

CoCrMo |

Excellent Biocompatibility, High Wear & Corrosion Resistance |

Dental crowns/bridges, Orthopedic Implants |

|

CuCrZr (Copper) |

Very High Thermal & Electrical Conductivity, Good Strength |

Heat sinks, Induction coils, Electrical connectors |

Advantages of SLM 3D Printing

1. Unparalleled Design Freedom: Create complex geometries (internal channels, lattices, organic shapes) impossible with machining or casting. Enables topology optimization for lightweight, high-performance parts.

2. Part Consolidation: Combine multiple components into a single, integrated part. Reduces assembly time, weight, potential failure points, and inventory.

3. Prototyping & Iteration: Quickly produce functional metal prototypes for testing and design validation, accelerating development cycles significantly.

4. Mass Customization: Economically produce small batches or even one-off customized parts (e.g., patient-specific medical implants, bespoke automotive components).

5. Complex Internal Features: Fabricate conformal cooling channels in molds/tooling for drastically improved cycle times and part quality. Create internal manifolds or fluid paths.

6. Material Efficiency: Near-net-shape production minimizes raw material waste compared to subtractive machining. Unused powder is largely recyclable.

7. High-Performance Materials: Process advanced, difficult-to-machine alloys like Titanium and Nickel Superalloys into complex shapes.

8. Reduced Lead Times: Especially for complex parts, SLM can significantly shorten the time from design to functional component compared to traditional methods involving tooling.

Limitations of SLM 3D Printing

1. High Cost: Significant capital investment in machines, high material costs (powder), and labor-intensive post-processing make SLM expensive compared to mass production techniques like casting or stamping. Best suited for low-to-medium volumes or high-value parts.

2. Build Size Limitations: Parts are confined to the dimensions of the printer's build chamber.

3. Surface Finish & Accuracy: As-built surfaces exhibit a characteristic roughness and "stair-stepping" effect. Dimensional accuracy is good but typically requires post-machining for tight tolerances and fine finishes.

4. Support Structures & Orientation: Supports are necessary for overhangs and to manage thermal stresses, adding material/time cost and requiring manual removal. Part orientation significantly impacts support needs, surface quality, and build time.

5. Residual Stresses & Distortion: Rapid heating and cooling cycles induce internal stresses. Careful process parameter tuning and support strategies are critical to minimize distortion and cracking. Stress-relief heat treatment is often mandatory.

6. Process Complexity & Expertise: Operating SLM machines and designing parts optimally requires specialized knowledge and experience in metallurgy, process parameters, and design for AM (DfAM).

7. Porosity & Defects: Achieving 99.9%+ density is possible but requires optimal parameters. Potential defects include lack-of-fusion porosity, keyholing (excessive vaporization), and entrapped gas pores.

8. Material & Process Certification: Qualification for safety-critical applications (aerospace, medical) requires rigorous material testing, process validation, and documentation, adding cost and time.

Post-Processing Options for SLM Parts

Support Removal: Manual removal using cutting tools or CNC machining. Requires care to avoid damaging the part.

Stress Relief Heat Treatment: Essential to reduce internal stresses caused by rapid solidification, minimizing distortion risk during subsequent machining or in service.

Hot Isostatic Pressing (HIP): A high-pressure, high-temperature process used primarily for critical components (aerospace, medical) to eliminate internal porosity and further improve mechanical properties (especially fatigue strength).

Solution Annealing & Aging (for specific alloys): Heat treatments (like for Titanium or Precipitation Hardening Stainless Steels) to achieve the desired final microstructure and mechanical properties.

Surface Finishing:

Abrasive Techniques:

• Sandblasting (aluminum oxide)

• Bead Blasting (glass/ceramic beads)

• Tumbling (vibratory barrel finishing)

Polishing: Mechanical (abrasive belts) or electrochemical (mirror finishes)

Coatings:

• Spray Painting (liquid coatings)

• Powder Coating (electrostatic dry powder + curing)

• Electroplating (chromium/nickel for wear resistance)

• Electrocoating (e-coating for complex geometries)

• Screen Printing: Adds logos/identification

Image Courtesy of Hi3DP

3D Printed Metal Parts Applications

Aerospace & Defense

Lightweight structural brackets, complex fuel nozzles, turbine blades, heat exchangers, satellite components, drone parts.

Medical & Dental

Patient-specific implants (cranial, spinal, hip, knee), surgical guides and instruments, dental crowns, bridges, and frameworks.

Automotive & Motorsport

Lightweight components (brackets, housings), topology-optimized parts, custom cooling channels for engines/brakes, bespoke components for racing.

Tooling & Molds

Injection molds and die casting inserts with conformal cooling channels (reducing cycle times by 30-70%), jigs, fixtures, gauges.

Energy

Turbine components (gas, steam), heat exchangers, downhole oil & gas tools, components for nuclear fusion research.

Industrial Machinery

Complex pump impellers and housings, valves, manifolds, custom robotics components, heat sinks.

Consumer Goods

High-end bicycle components, bespoke watch cases, luxury goods, customized sporting equipment.

Image Courtesy of Hi3DP

Factors That Affect the 3D Printed Metal Part Cost

Material Cost: Metal powders are significantly more expensive than bulk material. Alloy type (e.g., Titanium vs. Aluminum) dramatically impacts cost.

Machine Time: Build time depends on part volume, height (number of layers), laser scan speed, and layer thickness. Taller, denser parts take longer and cost more.

Part Geometry & Orientation: Complex geometries requiring dense supports increase material usage and build time. Optimal orientation minimizes supports and height.

Build Volume Utilization: Packing the build chamber efficiently with multiple parts amortizes fixed costs (machine time, inert gas, setup). One large part or several small parts sharing a build lowers cost per part.

Post-Processing: Machining, heat treatment (especially HIP), surface finishing, and NDT add substantial cost. Complexity dictates post-processing effort.

Setup & Programming: Includes CAD preparation, support generation, slicing, machine setup, and process parameter optimization.

Certification & Documentation: Required traceability and testing for regulated industries add overhead.

SLM 3D Printing Services at Hi3DP

Hi3DP provides professional SLM printing service and comprehensive metal 3D printing service solutions, making this advanced technology accessible and reliable. Our online metal printing service streamlines the process:

Advanced SLM Technology: We operate SLM machines in controlled environments, ensuring consistent, high-quality builds.

Wide Material Portfolio: Access a broad range of certified 3D printed metals including Titanium (Ti6Al4V), Aluminum (AlSi10Mg, A-6061), Stainless Steels (316L, 17-4 PH), Nickel Alloys (Inconel 718), Tool Steels (Maraging), and more.

Expertise & DfAM Support: Our engineering team offers Design for Additive Manufacturing (DfAM) consultation to optimize your part for SLM, minimize costs, and ensure manufacturability. We handle complex support generation and orientation.

End-to-End Post-Processing: We provide a full suite of post-processing capabilities, such as spray, painting, electrocoating, electroplating, bead blasting, polishing, powder coating, sandblasting, screen printing, tumbling, and tapping/ threading, etc.

Quality Assurance: Rigorous process control, material traceability, and inspection protocols ensure parts meet your specifications and industry standards.

Secure Online Quoting & Ordering: Our user-friendly online metal printing service platform allows for easy file upload, instant quoting (where possible), and order tracking.

Applications Focus: We specialize in functional prototypes, tooling inserts (conformal cooling), end-use production parts, lightweight structures, and complex fluidics.

Image Courtesy of Hi3DP

FAQs

Q: Is SLM the same as DMLS?

A: Technically, SLM implies full melting, while DMLS implies sintering/partial melting. However, in modern industrial practice, both terms often refer to fully melted processes using similar machines. Focus on the material specifications and achieved density (typically >99.5%) rather than the acronym. Hi3DP uses fully melting SLM processes.

Q: Can SLM parts be made watertight or pressure tight?

A: Yes, fully dense SLM parts are inherently pressure tight. HIP further ensures leak-tightness, making SLM ideal for manifolds, pumps, and fluid systems.

Q: Can you print multi-material parts with SLM?

A: Currently, SLM machines primarily print one material per build.

Q: Is the unused powder reusable?

A: Yes, a significant portion (typically 90-95%) of the unfused powder can be sieved, potentially blended with virgin powder, and reused for subsequent builds, improving material efficiency. Powder reuse strategies are carefully managed to maintain quality.

Q: How long does it take to print a part?

A: Build time varies massively based on part size, complexity, and machine parameters. Small, simple parts might take hours, while large, dense parts can take days.