Image Courtesy of Colorfabb

What is Shore Hardness?

Shore hardness measures how resistant a material is to indentation using a standardized durometer test. For flexible materials like TPU, the Shore A scale is used; for harder plastics, Shore D applies.

Scale Basics

• Shore A (TPU-relevant): 60A–100A typical; lower numbers feel softer and more rubber-like.

• Shore D (rigid plastics): 0D–100D; not used for conventional flexible TPU.

How It’s Measured

• Durometer: A spring-loaded indenter presses into the material with a standard force; the depth of indentation is converted to a hardness value.

• Test conditions matter: Thickness, backing, and dwell time (often 1 second and up to 15 seconds) affect readings.

What Hardness Tells You

• Soft TPU (≈85A–90A): Cushions impact, bends and stretches easily, seals well.

• Medium TPU (≈92A–95A): Balanced feel; flexible yet supportive under load.

• Hard TPU (≈98A): Much stiffer; holds shape, resists deformation, closer to semi-rigid plastics.

Analogy

A band of 85A TPU feels like a sturdy rubber band; 98A feels closer to a car tire tread.

TPU Filament and Shore Hardness Basics

TPU’s behavior changes predictably with hardness, but the print experience and part performance are also influenced by formulation and printer setup.

• Typical TPU Shore A Range: 85A–98A

• Covers soft elastomers to near-rigid grades. Most general-purpose filaments cluster around 92A–95A.

Property Trends (as hardness increases)

• Flexibility: Decreases—parts bend less and recover faster.

• Abrasion resistance: Generally increases—hard grades wear more slowly.

• Cut/tear resistance: Often increases with hardness, though geometry and infill matter.

• Compression set: Usually decreases—harder TPUs rebound more consistently after squeezing.

• Hysteresis/energy return: Harder TPUs dissipate less energy; softer TPUs absorb more vibration.

Printability Realities

• Soft (85A–90A): Demands tight filament path control; slower speeds, minimal retraction, direct drive strongly preferred.

• Medium (92A–95A): Most forgiving; workable on well-tuned Bowden systems; good balance of speed and quality.

• Hard (98A): Prints closer to standard materials; faster speeds, crisper detail, reduced stringing.

Environmental Performance

• Chemicals: TPU resists many oils and greases; specific resistance depends on formulation.

• Temperature: Typical service −30°C to 80–100°C; softer TPUs may feel mushier at high temps.

• UV/weathering: Varies; stabilized grades perform better outdoors; check datasheets.

Shore Hardness Grades Explained

|

Shore hardness (A) |

Flexibility |

Typical Use Cases |

Print Difficulty |

Notes |

|

85A–90A (Soft) |

Very soft, elastic, easy to bend and stretch |

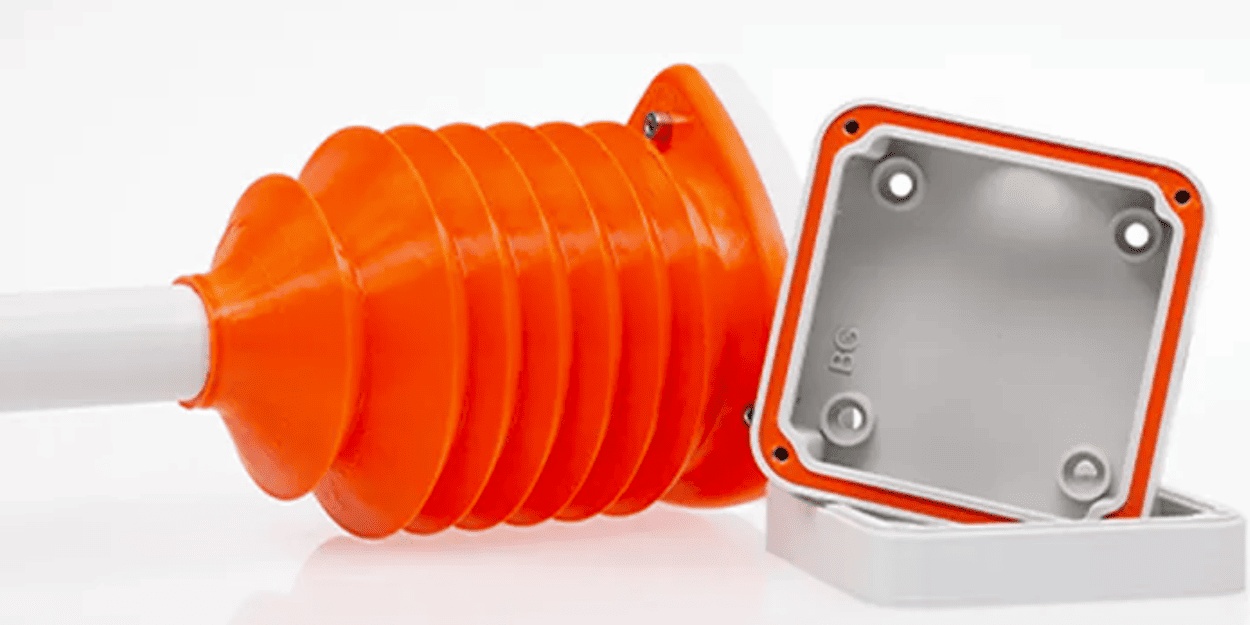

Gaskets, seals, wearables, shock/vibration dampers, soft grips |

High |

Direct drive preferred; slow speeds; minimal retraction; excels at sealing and cushioning |

|

92A–95A (Medium) |

Balanced—flexible yet supportive |

Phone cases, general grips, protective covers, hinges, robotics pads |

Medium |

Best all-rounder; good durability and abrasion resistance; workable on tuned Bowden |

|

98A (Hard) |

Stiff, semi-rigid, holds shape |

Wheels/rollers, snap-fit components needing compliance, functional housings |

Low |

Faster prints; crisper features; less flex—design for living hinges or thin walls if flexibility is needed |

Factors to Consider When Choosing Shore Hardness

Application Requirements

• Softer (85A–90A) for cushioning, seals, conformal contact.

• Medium (92A–95A) for protective covers, grips, and shock absorption with shape retention.

• Hard (98A) for parts that must hold geometry under moderate loads.

Mechanical Stress Profile

• Load-bearing: Harder TPU resists creep better.

• Repeated bending/flex cycles: Medium TPU often gives the best fatigue life.

• Tear-prone features (slots, cutouts): Use medium/hard TPU and add fillets to reduce stress concentrations.

Environment and Exposure

• Heat: If operating near 80–100°C, consider harder TPU and design thin flexible regions where needed.

• Chemicals: Check specific resistance (oils, fuels, cleaning agents); formulations differ.

• Outdoors/UV: Use UV-stabilized TPU or protective coatings for longevity.

User Experience Level

• Beginner-friendly: Start with 92A–95A for fewer jams and cleaner surfaces.

• Advanced users: Explore 85A–90A once your filament path and retraction are dialed in.

Cost and Availability

• Medium grades are widely available and price-stable.

• Specialty soft or hard grades may cost more and have stricter printing windows.

Hi3DP FDM 3D Printing Service: TPU 95A

If you need dependable flexibility with a professional finish, especially for prototypes that must behave like production parts, TPU 95A is a proven sweet spot.

Why 95A Hits the Sweet Spot:

• Balanced performance: Flexes under impact yet retains geometry; solid abrasion and tear resistance.

• Printability: Far fewer jams and stringing than ultra-soft grades; fine features stay crisp.

• Versatility: Works for consumer products, fixtures, soft-touch components, and light industrial seals.

What You Get with Hi3DP’s TPU 95A Service:

• Dialed process control: Tuned extrusion paths, constrained filament channels, and profiles optimized for elastomers.

• Consistent surface quality: Calibrated speeds and temperatures deliver smooth skins and uniform infill bonding.

• Design-for-flex guidance: Advice on wall thickness, ribbing, fillets, and infill to achieve target stiffness without over-hardening.

• Scalable production: From single functional prototypes to batch runs with repeatable tolerance windows.

• Quality checks: Dimensional verification and bend/flex tests on request.

Ideal Use Cases at 95A:

• Protective cases and bumpers that combine shock absorption and grip.

• Flexible couplers and feet that reduce vibration without collapsing.

• Soft-touch handles with durable texture and wear resistance.

• Conformal seals where medium compliance ensures both sealing and durability.

FAQs

Q: Can I get soft, glove-like flexibility with 95A?

A: Yes, via design. Use thin walls (0.8–1.2 mm), low infill (10–20%), and compliant lattices (gyroid) to mimic softer behavior without switching filament.

Q: Does infill pattern matter for TPU?

A: Absolutely. Gyroid and tri-hex provide isotropic compliance and good energy absorption. Grid or rectilinear feels stiffer along axes. Pattern choice changes “feel” as much as hardness.

Q: What causes stringing with soft TPU?

A: Low melt viscosity and elastic filament pushback. Mitigate with lower temps, short/slow retractions (or none), clean nozzle, short filament path, and moderate travel speeds. Dry filament reduces micro-bubbling that worsens stringing.

Q: Is TPU suitable for outdoor parts?

A: Yes, with caveats. Use UV-stabilized grades and design drainage/venting to reduce water entrapment. Harder TPU may retain shape better under sun-heated conditions.

Q: When should I step up to Shore D materials instead?

A: When parts require minimal compliance, tight dimensional stability under load, or high-temperature service beyond typical TPU ranges. Consider TPE blends or rigid engineering plastics for those cases.