Banner Image Courtesy of Polymaker

What Is Polycarbonate Filament?

Polycarbonate filament is a 3D printable form of the engineering thermoplastic polycarbonate (often abbreviated PC). Unlike hobby plastics such as PLA, polycarbonate is designed for functional parts that need high impact resistance, dimensional stability at elevated temperatures, and good mechanical performance.

PC filaments come in pure grades and in blended/modified grades (e.g., PC+ABS, PC blended with glass or carbon fibers) that change strength, stiffness, and ease of printing. Because PC requires higher extrusion and bed temperatures and benefits from an enclosed build environment, it’s commonly used on mid- to high-end FDM printers and by professional 3D printing services.

Key Material Properties

1. High Strength and Toughness: PC has excellent impact resistance and flexural strength, making it suitable for load-bearing parts.

2. Heat Resistance: Glass transition temperature is typically around 145°C, so parts retain stiffness at much higher temperatures than PLA or PETG.

3. Good Dimensional Stability: PC resists creep and maintains geometry under heat and load better than many hobby plastics.

4. Optical Clarity (certain grades): Some PC variants are transparent or translucent when printed and polished.

5. Chemical Resistance: PC is reasonably resistant to oils and many dilute chemicals, but strong solvents and alkalis can cause degradation.

6. Hygroscopic: PC absorbs moisture from the air; prints and filament can suffer from bubbles, stringing, or poor interlayer adhesion if the filament isn’t dried.

7. Requires Higher Process Control: Successful printing often needs an all-metal hotend, heated bed, enclosure, and careful bed adhesion strategies.

Pros and Cons of 3D Printing PC Filament

|

Pros |

Cons |

|

Polycarbonate offers exceptional impact resistance and toughness for functional, load-bearing parts. |

PC requires very high extrusion temperatures and an all-metal hotend. |

|

PC retains stiffness and dimensional stability at much higher temperatures than PLA or PETG. |

Successful prints need a heated bed and an enclosed chamber to avoid warping and delamination. |

|

When printed correctly, PC forms strong layer bonds that produce durable end-use parts. |

Polycarbonate filament is hygroscopic and must be dried and stored sealed to prevent print defects. |

|

Certain PC grades can be clear or translucent, enabling light-guiding and optical applications. |

PC is more challenging to print than hobby filaments and is not recommended for absolute beginners. |

|

PC is available in blends (PC+ABS, glass- or carbon-reinforced) so properties can be tuned for specific needs. |

Higher-temperature printing can release fumes, so good ventilation or filtration is required. |

|

Good resistance to creep and heat makes PC suitable for prototypes and parts used under continuous load. |

Achieving final dimensional stability or a smooth finish often requires post-processing such as annealing or sanding. |

Recommended Printer Settings

1. Nozzle / Hotend: All-metal hotend capable of stable temperatures to ~300–320°C. Nozzle diameter: 0.4 mm common; larger nozzles (0.6–0.8 mm) help with strength and faster prints.

2. Extrusion Temperature: 260–320°C depending on filament grade (check manufacturer recommendations). Start in the middle of the range and adjust for flow and surface finish.

3. Bed Temperature: 90–120°C; use PEI, glass with appropriate adhesive, or specialty build surfaces for adhesion.

4. Enclosure: Strongly recommended as the enclosure can maintain ambient chamber temperature to prevent warping and layer splitting.

5. Print Speed: 30–60 mm/s for best results; slower speeds improve layer bonding.

6. Layer Height: 0.1–0.3 mm depending on part detail vs. strength trade-offs. Thicker layers can increase strength.

7. Cooling: Minimal or no part cooling; active cooling can promote layer delamination.

8. Retraction: Moderate retraction settings to avoid oozing, but avoid excessive retraction that can clog at high temps.

9. Drying: Dry filament at 70–80°C for 4–6 hours (or follow manufacturer instructions) if it shows signs of moisture (popcorning, bubbles, rough surface). Store filament in sealed containers with desiccant.

10. Adhesion Aids: Use a brim, raft, or adhesive like PVA glue stick for tricky geometries.

Top Applications for FDM Printed PC Parts

Functional End-Use Parts

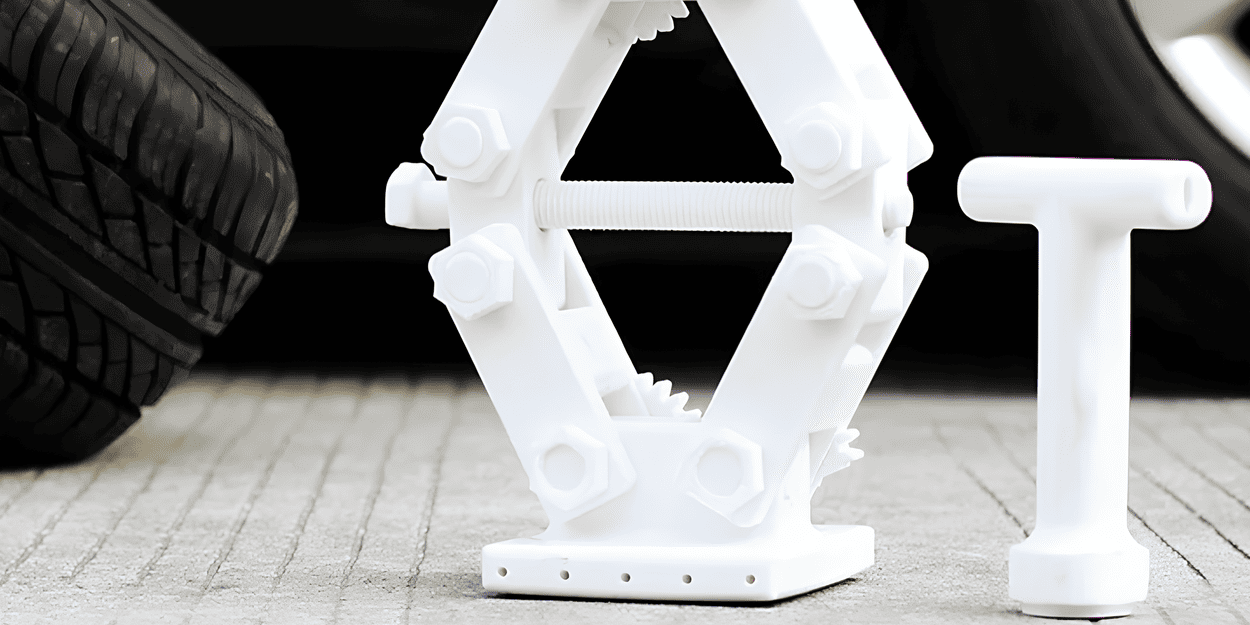

Gear housings, brackets, tool handles, jigs and fixtures that need toughness and heat resistance.

Automotive Components

Interior mounts, clips, and custom fixtures are exposed to elevated temperatures.

Electronics Enclosures

Cases for devices that generate heat or are used near warm components.

Mechanical Prototypes

Functional prototypes that must replicate real-world mechanical loading without failing.

Medical Devices (non-implant)

Durable components for diagnostic fixtures, jigs, or instrument housings, validate biocompatibility per application.

Light-guides, lenses, and ducts when using clear PC grades and appropriate post-processing.

Try Hi3DP FDM 3D Printing Service

Looking to skip the calibration and dial-in work?

Here’s why thousands of customers trust Hi3DP:

Instant Quotes & Rapid Turnaround: Upload your STL, choose PETG, and get pricing within minutes—shipped in as little as 2 business days.

Quality Assurance: Parts undergo dimensional inspection and strength testing to meet your specifications.

Custom Finishes & Assembly: Post-processing options include sanding, painting, and chemical smoothing. Assembly and kitting services are available for multi-part projects.

Global Shipping & Support: Whether you’re in North America, Europe, or Asia, we deliver reliable quality worldwide.

FAQs

Q: Is polycarbonate filament easy to print?

A: No. PC is more challenging than PLA or PETG. It needs high extrusion temperatures, good bed adhesion, and an enclosure to prevent warping.

Q: Does polycarbonate require a special nozzle?

A: PC is not abrasive like carbon-filled filaments, so a brass nozzle is typically fine; however, an all-metal hotend is essential to handle high temperatures.

Q: How do I avoid warping and layer separation?

A: Use a heated bed, enclosure, stable build surface, adequate first-layer settings (slower speed, slightly higher extrusion), and consider annealing parts post-print to relieve stresses.

Q: Can PC parts be painted or glued?

A: Yes. Surface prep (sanding, priming) improves paint adhesion. For structural bonding, use adhesives recommended for polycarbonate or mechanical fasteners.

Q: Are PC parts food-safe?

A: Generally, no. Standard PC filaments and FDM processes are not food-safe without specific materials and validated processes. Use certified materials and post-process appropriately, or opt for services that can validate food contact compliance.