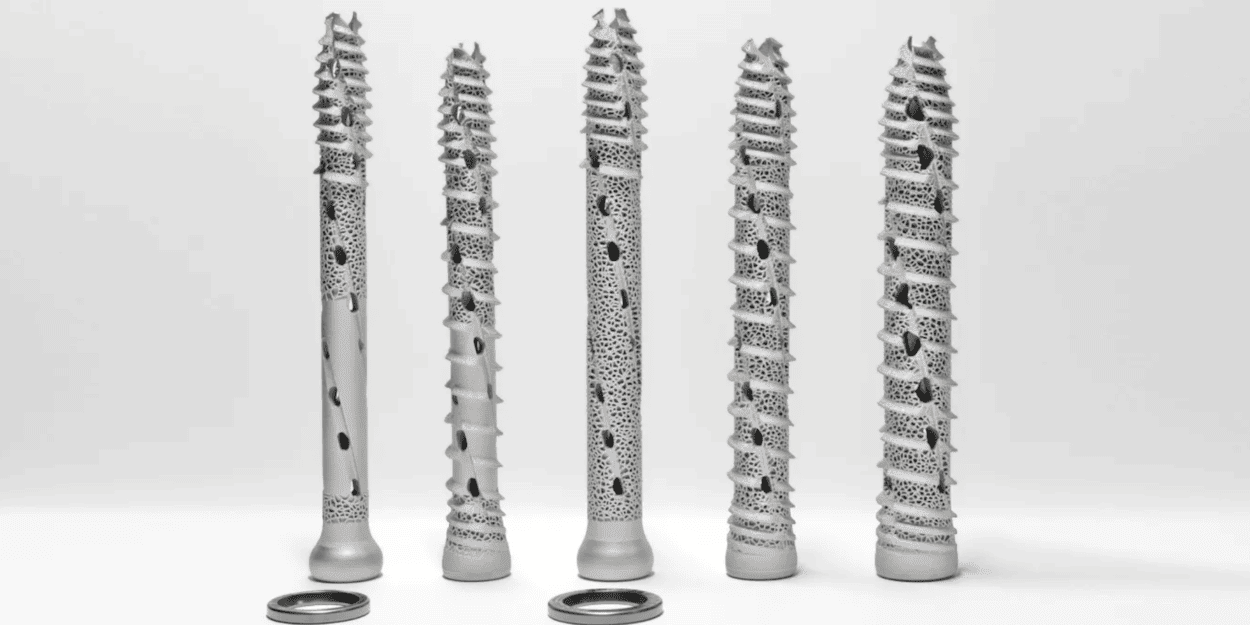

Banner Image Courtesy of nTop

In recent years, additive manufacturing (commonly known as 3D printing) has emerged as a game-changer in healthcare—especially in the realm of custom implants and prosthetics. Traditional off-the-shelf devices often force compromise between fit, comfort, and functionality. By contrast, patient-specific 3D-printed parts leverage medical imaging and digital design to deliver tailor-made solutions that dovetail perfectly with each individual’s anatomy.

The Need for Custom Implants & Prosthetics

Limitations of Off-the-Shelf Devices. Standardized implants and prosthetic sockets come in a limited range of sizes and shapes, often leaving patients with suboptimal fit. Poorly fitting implants can cause discomfort, improper load distribution, and—even worse—premature revision surgeries.

Complex Anatomies and Challenging Cases. Patients with congenital anomalies, tumor resections, or severe trauma frequently present irregular bone structures that standard devices cannot accommodate. Custom implants enable surgeons to address unique anatomical challenges in craniofacial reconstruction, orthopedic revisions, and complex limb-difference cases.

Improved Patient Outcomes. Studies have shown that custom-fit devices can reduce intraoperative adjustments, lower complication rates, and accelerate rehabilitation. By designing components that mirror a patient’s specific anatomy, surgeons can achieve better biomechanical performance, leading to enhanced mobility and quality of life.

From Scan to Part: The 3D Printing Workflow

Medical Imaging & Data Capture

The journey begins with high-resolution imaging—CT scans for bony structures and MRI for soft tissues. In cases of prosthetics, 3D surface scanners capture the residual limb’s exact contours to design comfortable sockets.

Digital Design & Surgical Planning

Specialized software converts imaging DICOM files into a 3D mesh. Engineers and surgeons collaborate in CAD environments to model the implant or prosthetic, simulate its fit, and adjust geometry for optimal load paths. Virtual surgical planning tools allow teams to rehearse placement and osteotomies before entering the operating room.

Additive Manufacturing Processes

Selective Laser Melting (SLM): Ideal for metal implants, SLM fuses metal powder (e.g., titanium or cobalt-chrome) layer by layer under a high-power laser, creating fully dense, load-bearing parts.

Stereolithography (SLA) / Digital Light Processing (DLP): These resin-based processes deliver high resolution (<50 µm) for complex polymer parts such as prosthetic sockets, surgical guides, or trial implants.

Post-Processing & Quality Assurance

Printed parts undergo heat treatments to relieve stress and refine microstructure (in metals), followed by support removal, surface finishing, and sterilization. Non-destructive evaluation—such as CT inspection—verifies internal geometry and detects defects. Every step is tracked through rigorous documentation to meet regulatory standards.

Materials & Technologies Driving Customization

Titanium & Cobalt-Chrome Alloys. Renowned for biocompatibility, high strength-to-weight ratio, and corrosion resistance, these metals form the backbone of load-bearing implants in orthopedics and craniomaxillofacial surgery.

High-Performance Polymers. PEEK (polyether ether ketone) offers radiolucency and mechanical properties closely matching cortical bone, making it an excellent choice for spinal cages and non-metallic implants. Medical-grade resins for SLA deliver fine detail for surgical guides and prototype testing.

Emerging Bio-inks. Researchers are developing cell-laden hydrogels and growth-factor-enhanced inks to print cartilage, skin grafts, and even vascularized tissue constructs. Though still in preclinical stages, these approaches promise living implants that integrate seamlessly with host tissue.

Multi-Material & Hybrid Printing. Combining metals and polymers in a single build—or integrating 3D-printed parts with conventional machining—enables devices with graded stiffness, complex internal lattice structures, and tailored porosity for bone ingrowth.

Benefits and Limitations of 3DPrinted Custom Medical Parts

Benefits

Anatomical Accuracy & Fit. Perfect replication of patient anatomy translates to fewer surgical adjustments and more predictable outcomes.

Speed & Agility. From imaging to a finished device in days, point-of-care printing shortens lead times compared to traditional machining and mold-making.

On-Demand Production. Hospitals and service bureaus can maintain minimal inventories, producing parts only as needed—reducing waste and storage costs.

Enhanced Functionality. Internal lattice structures and porous surfaces promote osseointegration and reduce implant weight without sacrificing strength.

Limitations

Regulatory Complexity. Navigating FDA guidance and ISO/ASTM standards for patient-specific devices demands extensive documentation, design validation, and traceability.

Cost of Entry. High-end metal printers, biocompatible materials, and qualified personnel require significant upfront investment—posing a barrier for smaller clinics.

Material Certification. Not all biocompatible resins or powders are approved for implantable use; sourcing certified materials can be challenging.

Workflow Integration. Incorporating 3D printing into existing clinical workflows involves training clinicians, establishing new protocols, and ensuring software interoperability.

The Future of Patient-Specific 3D Printing

Bioprinting Breakthroughs. As bio-inks evolve, we edge closer to printing functional cartilage, skin, and even organoids for transplantation—ushering in a new era of regenerative medicine.

AI-Driven Design & Digital Twins. Machine-learning algorithms will optimize device geometry automatically based on patient biomechanics, while digital twin simulations predict long-term implant performance under physiologic loads.

Decentralized Manufacturing Networks. Cloud-based platforms will connect hospitals worldwide to certified printing partners, enabling seamless ordering, design sharing, and quality-assured production regardless of location.

Living, Adaptive Implants. Scientists envision implants seeded with the patient’s cells that remodel over time, offering dynamic healing responses rather than inert replacements.

3D printing has already demonstrated its potential to transform how we design, manufacture, and deliver custom implants and prosthetics. By marrying medical imaging, advanced materials, and digital workflows, patient-specific devices are becoming more accessible, cost-effective, and clinically impactful.