Banner Image Courtesy of Polymaker

What is Polypropylene 3D Printer Filament?

Polypropylene (PP) filament is a semi‑crystalline thermoplastic widely used in consumer goods, automotive components, and packaging, now making its way into the 3D printing world. Known for its excellent chemical resistance, toughness, and fatigue endurance, PP is lightweight yet durable, making it ideal for functional parts that require repeated flexing or long‑term wear.

Unlike common PLA or ABS filaments, PP has a low density (~0.90 g/cm³), allowing you to produce parts that are both strong and lighter than those printed with most other materials. Its non‑toxic nature, food‑contact safety (in many grades), and resistance to moisture absorption add to its appeal for specialized applications.

However, PP is also one of the trickier materials to print, due to its low surface energy (making adhesion difficult) and its tendency to warp without careful setup.

Key Properties

1. Low Density (~0.90 g/cm³): Significantly lighter than PLA (~1.24 g/cm³) or ABS (~1.04 g/cm³). Finished parts weigh less, which is advantageous in applications like drones, automotive interiors, or wearables where weight reduction improves performance and efficiency.

2. High Fatigue Resistance: Exceptional ability to endure repeated bending without cracking, thanks to its ductility and flexible molecular chains.

3. Excellent Chemical Resistance: Immune to many acids, bases, and organic solvents such as alcohols, acetone, and most detergents.

4. Low Moisture Absorption: Hygroscopic uptake is almost negligible compared to nylon or PETG. It can be stored without drying for extended periods, and its dimensional stability in humid environments is excellent.

5. Food Contact Safety: Many commercial PP formulations comply with FDA/EU food safety regulations.

6. Semi‑Crystalline Thermal Behavior: PP’s crystallites result in a distinct melting point (~160–165 °C) and better heat deflection than amorphous materials like PLA.

7. Low Surface Energy: The material’s molecular surface doesn’t “wet” or bond easily to other substances. It causes notorious bed adhesion issues in FDM printing. Requires specialized build surfaces (like PP sheets or tape) or modified adhesives to prevent part detachment during printing.

Pros and Cons of PP Filament

|

Pros |

Cons |

|

Extremely lightweight |

Poor bed adhesion due to low surface energy |

|

Excellent fatigue resistance, ideal for hinges and snap‑fits |

High warping risk; requires special surfaces or adhesion techniques |

|

Outstanding chemical resistance |

Narrow processing window; needs dialed‑in temps |

|

Low moisture absorption |

Limited color availability compared to PLA/ABS |

|

Food‑safe grades available |

Not as rigid as PLA , may deform under heavy load |

Recommended Printer Settings

|

Setting |

Recommended Range / Tips |

Notes |

|

Nozzle Diameter |

0.4 mm or larger |

Standard size works; hardened steel if using glass‑filled PP |

|

Printing Temperature |

220–250 °C |

Follow manufacturer specs; too low = weak layers, too high = stringing |

|

Bed Temperature |

80–100 °C |

Helps reduce warping |

|

Bed Surface |

Polypropylene sheet, packing tape, or build surfaces designed for PP |

PP sticks best to itself; PEI/glass often fail |

|

Print Speed |

30–50 mm/s |

Slower improves adhesion and reduces stress |

|

Cooling |

Off or minimal (0–20%) |

Avoids layer separation in semi‑crystalline plastics |

|

Enclosure |

Recommended |

Maintains consistent temperature and minimizes warp |

Pro Tip: Printing on a polypropylene build plate (or even packaging tape made from PP) is one of the most reliable adhesion methods.

Top Applications

1. Living Hinges

PP’s flexibility and fatigue resistance make it perfect for one‑piece designs that can bend thousands of times without breaking.

2. Food‑Safe Containers

With food‑grade PP, you can create custom storage boxes, funnels, and utensils.

3. Chemical‑Resistant Parts

Ideal for laboratory bottles, chemical handling jigs, and automotive fluid system components.

4. Wear‑Resistant Clips & Fasteners

PP’s toughness suits snap‑fit designs, buckles, and retaining clips that need durability without brittleness.

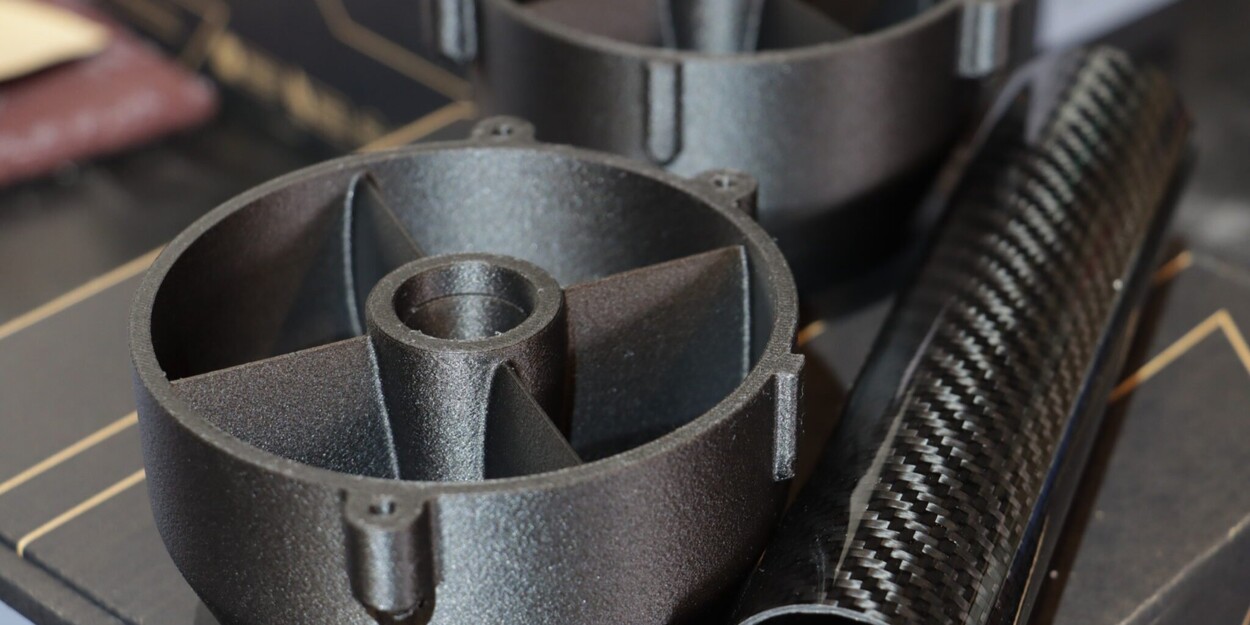

5. Lightweight Structural Parts

Automotive and drone components benefit from PP’s strength‑to‑weight ratio.

FAQs

Q: Is PP filament hard to print?

A: It’s more challenging than PLA or PETG due to bed adhesion issues, but with the right surface and temperature control, it’s very manageable.

Q: Can I print PP on a glass bed?

A: Not effectively. PP doesn’t adhere well to glass or PEI; use a PP sheet or PP‑based tape for best results.

Q: Is polypropylene filament food‑safe?

A: Many PP grades are food‑safe, but always check the manufacturer’s certification before printing food‑contact items.

Q: How strong is PP compared to PLA?

A: PP is less rigid than PLA but far superior in impact resistance and flexibility.

Q: Does PP absorb moisture?

A: Very little. Unlike nylon or PETG, PP rarely needs drying before use.

Polypropylene filament opens the door to lightweight, fatigue‑proof, and chemical‑resistant parts that go beyond hobby use into professional applications. While it demands more care in setup, especially for adhesion and warping.