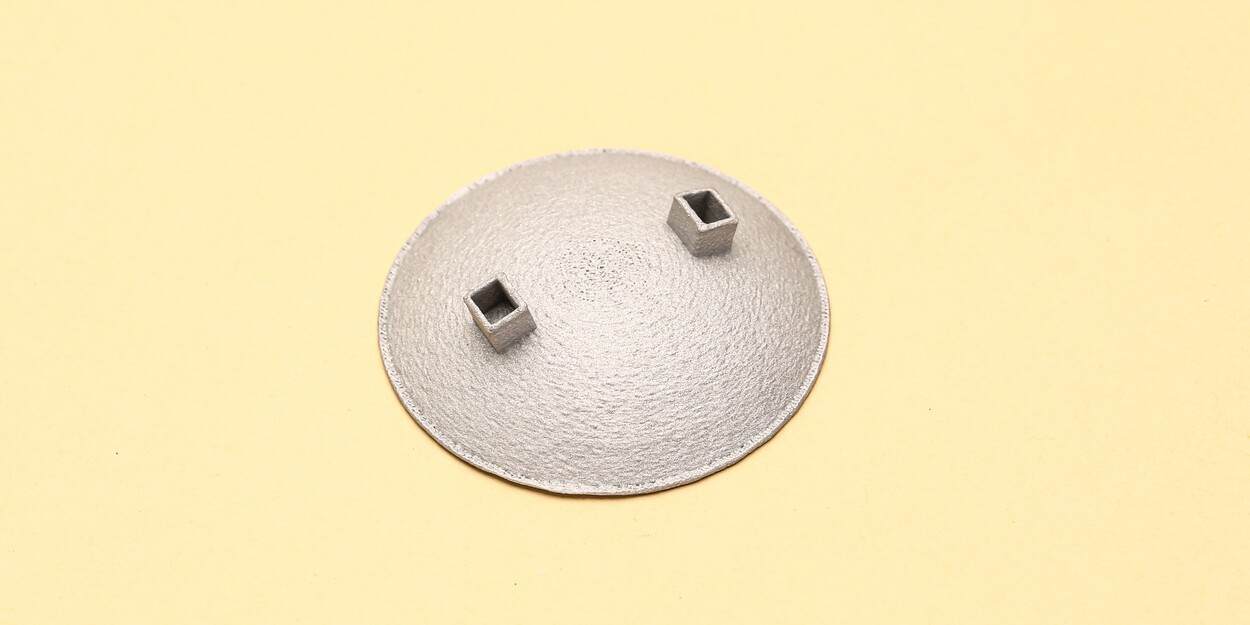

Banner Image Courtesy of Hi3DP

Key Processes for Aluminum 3D Printing

Aluminum 3D printing is most commonly achieved through metal additive manufacturing techniques that fuse fine aluminum powder or wire into solid parts. The main processes include:

1. Selective Laser Melting (SLM) / Laser Powder Bed Fusion (LPBF)

• How it works: A high-powered laser selectively melts layers of aluminum powder according to a CAD model.

• Advantages: Excellent mechanical properties, high density, and fine detail resolution.

• Limitations: Requires careful control of heat input to avoid warping or cracking.

• Best for: Aerospace, automotive, and high-performance engineering components.

2. Electron Beam Melting (EBM)

• How it works: Similar to SLM, but uses an electron beam in a vacuum chamber.

• Advantages: Lower residual stresses, faster build rates for certain geometries.

• Limitations: Coarser surface finish compared to SLM; limited alloy availability.

• Best for: Large, structural aerospace parts.

3. Binder Jetting

• How it works: A liquid binder selectively joins aluminum powder particles layer by layer, followed by sintering or infiltration.

• Advantages: High build speed, no need for support structures during printing.

• Limitations: Lower density and mechanical strength unless post-processed.

• Best for: Prototypes, low-load components, and cost-sensitive applications.

Common Aluminum Alloys Used in 3D Printing

|

Alloy |

Composition Highlights |

Key Benefits |

Typical Applications |

|

AlSi10Mg |

Aluminum with ~10% silicon, magnesium |

Excellent strength-to-weight ratio, good corrosion resistance, fine detail resolution |

Aerospace brackets, automotive parts, heat exchangers |

|

AlSi7Mg |

Slightly lower silicon content than AlSi10Mg |

Improved ductility, good thermal conductivity |

Molds, housings, structural parts |

|

Scalmalloy® |

Aluminum-magnesium-scandium |

Exceptional strength, high fatigue resistance |

Aerospace, motorsports, high-performance engineering |

|

A357 |

Aluminum-silicon-magnesium |

High corrosion resistance, good weldability |

Marine components, automotive |

|

Custom R&D Alloys |

Tailored compositions |

Optimized for specific mechanical or thermal properties |

Specialized industrial applications |

Properties of 3D Printed Aluminum

1. Mechanical Properties

• Tensile Strength: Typically 320–500 MPa for AlSi10Mg after heat treatment.

• Yield Strength: Around 230–400 MPa depending on process and alloy.

• Fatigue Resistance: Enhanced in alloys like Scalmalloy, making them ideal for cyclic load applications.

2. Thermal Properties

• Thermal Conductivity: Lower than wrought aluminum due to microstructural differences, but still suitable for heat exchangers.

• Heat Resistance: Stable up to ~200°C for most alloys; higher for specialized compositions.

3. Density & Porosity

• Density: Up to 99.9% of theoretical density with optimized SLM parameters.

• Porosity: Can be minimized with proper laser power, scan speed, and powder quality.

4. Surface Finish

• As-printed surfaces are typically rougher than machined aluminum (Ra 6–12 μm), requiring post-processing for critical surfaces.

SLM 3D Printed AlSi10Mg Properties at Hi3DP:

|

Dense Properties |

Metric |

Method |

|

Density |

2.65 g/cm3 |

WGE-Prod-067EN |

|

Relative Density |

99.0% |

WGE-Prod-067EN |

|

Mechanical Properties |

Metric |

Method |

|

Tensile Strength |

300MPa |

DIN EN ISO 6892-1:2009 |

|

Yield Strength |

190MPa |

DIN EN ISO 6892-1:2009 |

|

Elongation at Break |

2% |

DIN EN ISO 6892-1:2009 |

|

Elastic Modulus |

70GPa |

DIN EN ISO 6892-1:2009 |

|

Surface Properties |

Metric |

Method |

|

Roughness Ra |

16 µm |

ISO 4287 / AITM 1-00070 |

|

Roughness Rz |

70 µm |

ISO 4287 / AITM 1-00070 |

SLM 3D Printed Aluminum 6061 Properties at Hi3DP:

|

Dense Properties |

Metric |

Method |

|

Density |

2.8 g/cm3 |

WGE-Prod-067EN |

|

Relative Density |

99.0% |

WGE-Prod-067EN |

|

Mechanical Properties |

Metric |

Method |

|

Tensile Strength |

290MPa |

DIN EN ISO 6892-1:2009 |

|

Yield Strength |

240MPa |

DIN EN ISO 6892-1:2009 |

|

Elongation at Break |

10% |

DIN EN ISO 6892-1:2009 |

|

Elastic Modulus |

70GPa |

DIN EN ISO 6892-1:2009 |

|

Surface Properties |

Metric |

Method |

|

Roughness Ra |

16 µm |

ISO 4287 / AITM 1-00070 |

|

Roughness Rz |

70 µm |

ISO 4287 / AITM 1-00070 |

Advantages of Aluminum 3D Printing

1. Lightweight Strength: High strength-to-weight ratio ideal for aerospace and automotive.

2. Complex Geometries: Enables internal channels, lattice structures, and topology-optimized designs.

3. Material Efficiency: Minimal waste compared to subtractive machining.

4. Rapid Iteration: Faster prototyping and design validation.

5. Customization: Tailored parts for specific performance requirements.

6. Integration of Functions: Combine multiple components into a single printed part, reducing assembly time.

Limitations & Challenges

1. Printing Defects

• Porosity: Caused by gas entrapment or incomplete melting.

• Cracking: Due to high thermal conductivity and shrinkage stresses.

• Warping: Especially in large, thin-walled parts.

2. Cost Factors

• Material Cost: Aluminum powder is more expensive than bulk aluminum.

• Machine Cost: Metal AM systems require significant capital investment.

• Post-Processing: Machining, heat treatment, and surface finishing add time and expense.

3. Design Constraints

• Support structures are often required for overhangs.

• Minimum wall thickness typically ~0.8–1.0 mm for structural integrity.

4. Alloy Limitations

• Not all traditional aluminum alloys are printable due to cracking susceptibility.

Applications Across Industries

Aerospace

Aluminum 3D printing is widely adopted in aerospace for its ability to deliver lightweight yet strong components. By reducing part weight, manufacturers can improve fuel efficiency and payload capacity. Common applications include satellite brackets, heat exchangers, and structural supports that must endure extreme conditions while minimizing mass.

Automotive & Motorsports

In the automotive sector, especially in high-performance and racing environments, aluminum 3D printing enables the production of lighter, stronger parts that enhance speed and handling. Engine components, suspension parts, and custom racing elements can be optimized for both performance and durability.

Robotics & Drones

For robotics and unmanned aerial vehicles, weight reduction directly translates to longer operational times and greater payload capacity. Aluminum’s strength-to-weight ratio makes it ideal for drone arms, robotic grippers, and sensor housings that require both precision and resilience.

Medical

The medical industry benefits from aluminum 3D printing’s ability to produce biocompatible, customized tools and devices. Surgical instruments, orthopedic implants, and prosthetic components can be tailored to individual patient needs while maintaining high strength and corrosion resistance.

Marine

In marine environments, corrosion resistance is critical. Aluminum 3D printing is used to create propeller blades, structural fittings, and other components that must withstand constant exposure to saltwater without compromising performance.

Consumer Products

From sports equipment to high-end electronics housings, aluminum 3D printing allows designers to merge aesthetics with functionality. The technology supports intricate designs, personalized features, and durable finishes that appeal to premium markets.