Core Post-Processing Steps of 3D Printed Resin

1. Support Removal & Initial Cleanup

After your SLA printing services deliver the raw parts, our Hi3DP-approved suppliers begin by carefully cutting away supports. Mechanical tools (flush cutters, pliers) remove most supports without scarring, while delicate corners get a gentle chemical soak to minimize stress on thin features.

2. Precision Washing & Degreasing

Residual uncured resin is the enemy of a smooth finish. Parts undergo a multi-stage wash—first, in isopropyl alcohol to dissolve the surface resin, then in a fresh solvent with ultrasonic agitation to flush internal channels, which ensures every cavity and overhang is pristinely clean.

3. Controlled UV Curing

Correct post-cure is vital to full material properties. Using programmable UV ovens calibrated for each resin chemistry, our suppliers apply precisely timed, multi-angle exposure. The cured parts have optimal strength, reduced brittleness, and uniform color.

4. Surface Refinement & Finishing

To achieve the gloss or matte finish you need, parts are sanded from 400 to 2000 grit. For ultra-smooth or semi-opaque looks, a primer coat is applied before final polishing. Every surface is inspected under magnification to confirm defect-free results.

5. Quality Inspection & Documentation

Hi3DP-authorized partners perform dimensional checks with calipers or CMM, measure surface roughness and record batch results. You receive a full inspection report alongside your parts—ensuring traceability and consistent quality every time.

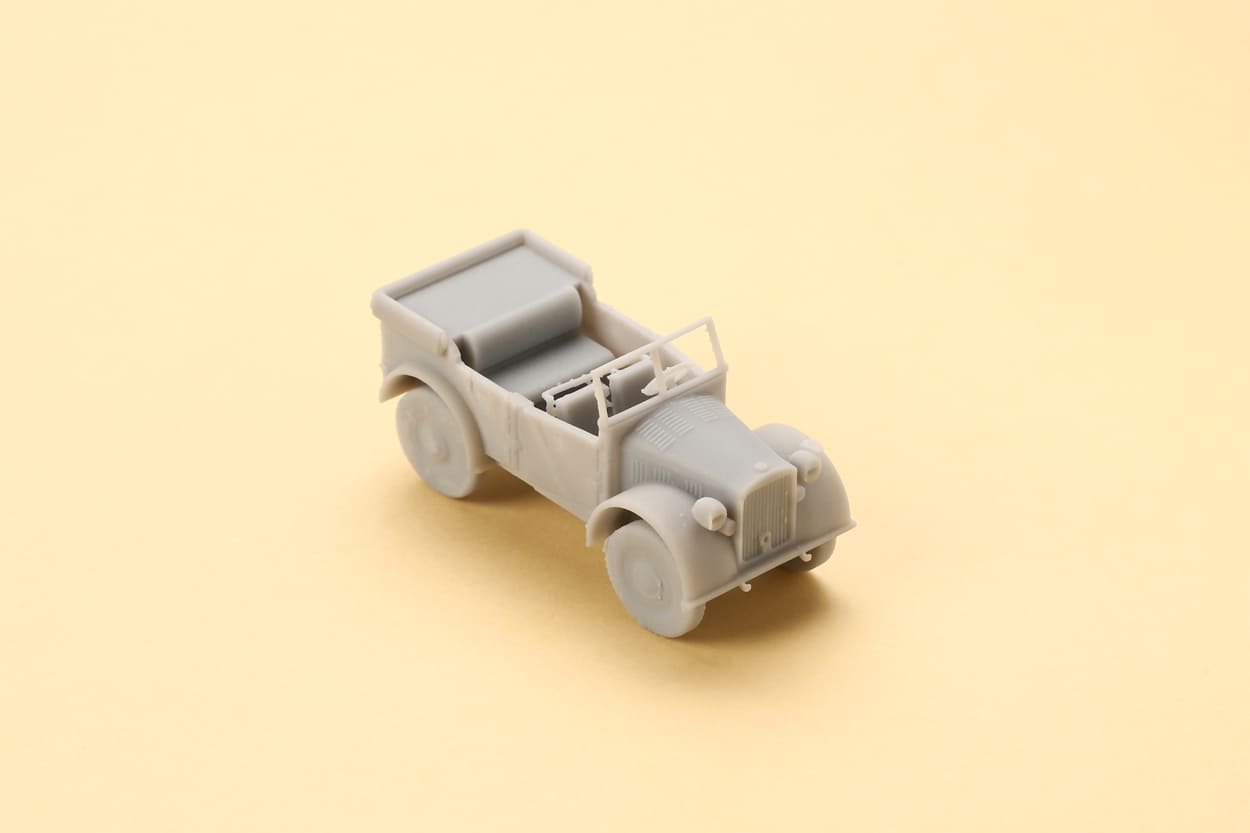

Image Courtesy of Hi3DP

Why SLA Resin Post-Processing Matters

Enhanced Mechanical Properties

Proper SLA post-processing dramatically improves tensile strength and impact resistance. Under-cured parts remain brittle; over-cured parts warp. Our calibrated UV profiles unlock the full potential of SLA resins.

Superior Surface Quality

Untreated 3D printed resins often show layer lines, sticky patches, or micro-bubbles. Post-processing for SLA printed resins removes these imperfections, delivering parts ready for end-use applications or display.

Dimensional Accuracy & Fit

Resin shrinkage during cure can shift tolerances. By partnering with vetted suppliers who monitor each batch, Hi3DP ensures your functional assemblies—snap fits, gears, or housings—mesh perfectly.

Chemical & Biocompatibility Compliance

For medical prototypes, food-safe fixtures, or clear resin models, it’s critical to remove toxic residues and apply appropriate sealing. Our network’s certified processes meet ISO and USP standards where needed.

Specialized Options & Add-Ons

Boost your parts beyond basic finishing with these value-added services:

1. Spray Painting

Uniform, automotive-grade coatings in any Pantone color. Ideal for presentation models or consumer products.

2. Coating

Protective layers—epoxy, silicone, or Parylene—that add chemical resistance, weatherproofing, or biocompatibility.

3. Dyeing

Full-part immersion dye for translucent or opaque SLA resins. Creates vibrant, permanent coloration without surface roughening.

4. Electroplating

Thin metal layers (nickel, copper, chrome) are applied to resin parts for EMI shielding, conductivity, or metallic aesthetics.

5. Frosting (for clear resin)

Light-diffusing etch that transforms clear prints into frosted, diffuser-style optics.

6. Translucency & Transparency (for clear resin)

Fine polishing and resin-infused clearing agents yield glass-like clarity or controlled light diffusion.

7. Screen Printing

Durable legends, logos, or color graphics applied to flat or slightly curved surfaces.

8. Smooth Sanding

High-precision sanding to eliminate layer lines; available down to 3000 grit for mirror finishes.

9. Tapping & Threading

Precision tapping of standard or custom threads—ensures repeatable, secure assembly without secondary machining.

Image Courtesy of Hi3DP

Hi3DP’s Supplier Vetting & Quality Assurance

Rigorous Equipment Standards

We hand-select suppliers with industrial-grade wash stations, UV ovens, and finishing booths. Hobbyist gear simply doesn’t make the cut.

Material Traceability

Every batch of SLA resins used by our partners is logged with lot numbers and expiration dates—guaranteeing consistent material properties.

Operator Certification

Technicians undergo regular training on safety and process optimization for each resin type.

Performance Audits & KPIs

Turnaround times, defect rates, and customer feedback are tracked. Suppliers missing benchmarks are re-audited or replaced.

Safety & Environmental Protocols

Proper disposal of chemical waste, solvent recycling, and operator PPE standards protect both people and the planet.

How to Get Started with Hi3DP

Get your parts in just five simple steps and no sign-up required:

1. Upload Your 3D Files

Upload STL or other 3D file format on our platform, selecting your preferred resin from our extensive catalog.

2. Choose Your Finish & Add-Ons

In the quote form, pick basic post-processing or any specialized services—painting, plating, frosting, and more.

3. Review & Confirm Your Quote

Instant pricing reflects resin choice, part volume, and finish complexity. Need a custom option? Our team is standing by.

4. Track & Receive

Once approved, your job enters our network of Hi3DP-approved suppliers. You’ll get real-time updates and hassle-free shipping.

5. Enjoy Flawless Parts

Experience the peace of mind that comes with consistent, high-quality results. Perfect for prototyping, small-batch production, or final products.

For step-by-step instructions on using the Hi3DP platform, explore our complete user guide here.

Image Courtesy of Hi3DP