Multi Jet Fusion (MJF) 3D printing has emerged as a game-changer for producing functional, end-use parts and prototypes. Offering a unique blend of speed, precision, material properties, and cost-effectiveness, MJF printing service options are becoming the go-to solution for industries that demand high-quality nylon components. This guide delivers everything you need to know about MJF 3D printing, empowering you to leverage its capabilities effectively.

What is MJF 3D Printing?

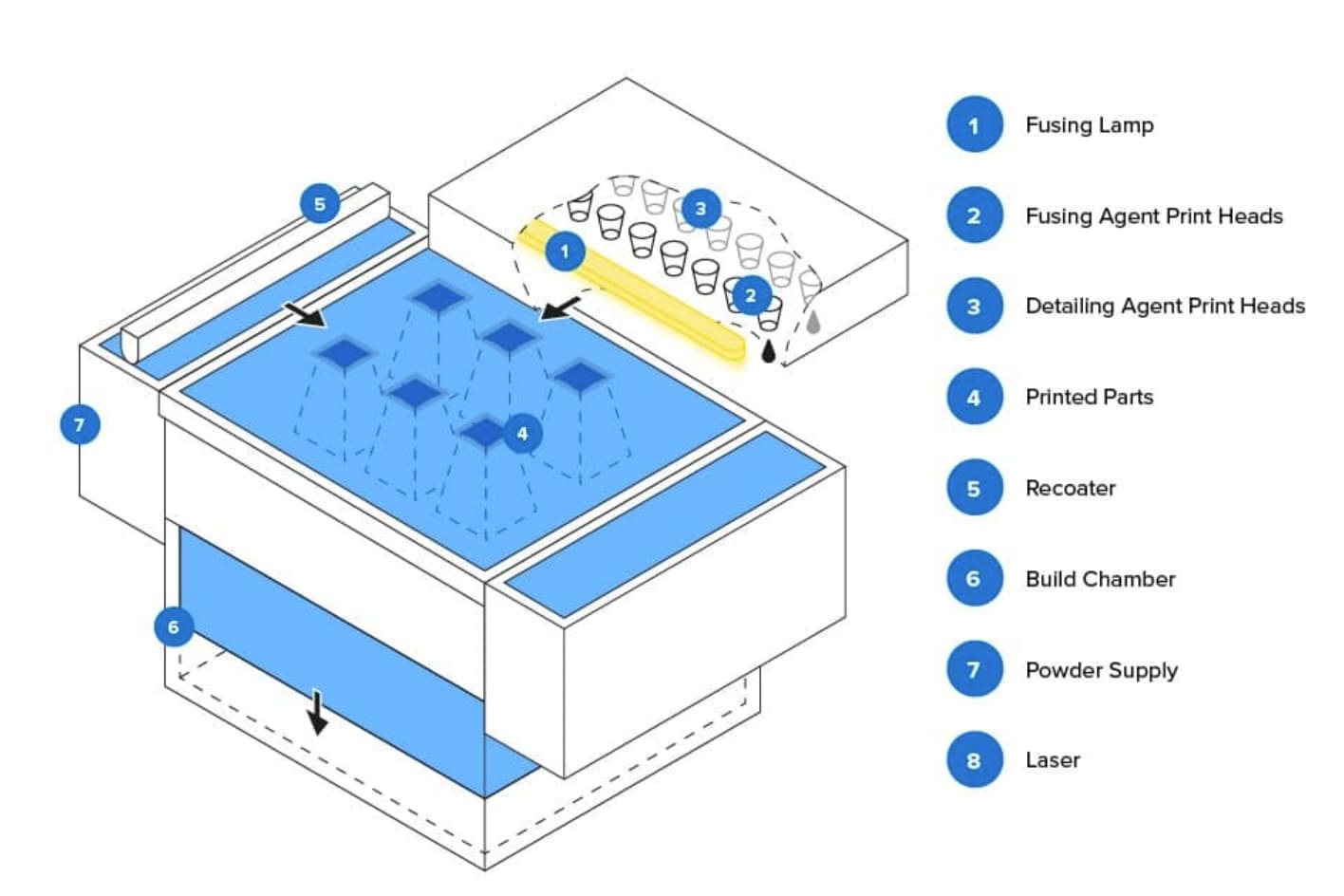

Multi Jet Fusion (MJF) is an industrial-grade 3D printing technology developed by HP. Unlike filament-based (FDM) or laser-sintering (SLS) methods, MJF uses a unique process involving inkjet arrays and thermal energy to selectively fuse powdered material, primarily nylon, layer by layer. The result is parts known for their:

Isotropic Mechanical Properties: Strength and performance are consistent in all directions, unlike some layer-dependent processes.

High Detail and Resolution: Fine features, thin walls, and complex geometries are achievable.

Excellent Surface Quality: Smoother surfaces directly out of the printer compared to many other powder-based processes.

Production-Grade Durability: Parts exhibit mechanical properties close to or exceeding injection-molded nylon.

Image Courtesy of Hi3DP

How Multi Jet Fusion Works

Powder Coating: A thin layer (typically 80 microns) of polymer powder (most commonly Nylon PA12) is evenly spread across the build platform by a recoater arm.

Fusing Agent Application: An array of inkjet nozzles selectively deposits a proprietary "fusing agent" onto the powder bed where the solid part material is desired.

Detailing Agent Application: Simultaneously, a second array deposits a "detailing agent" around the edges of the fused areas. This agent precisely controls the fusing process, improving part resolution and surface finish by inhibiting fusing where it's not wanted.

Infrared Energy Exposure: Powerful infrared lamps pass over the entire bed. The fusing agent absorbs this energy efficiently, causing the underlying powder particles to melt and fuse together. The detailing agent helps create crisp boundaries by reducing thermal bleed.

Lowering & Recoating: The build platform lowers by one layer thickness, and the recoater spreads a fresh layer of powder.

Repetition: Steps 2-5 repeat until the entire part (or batch of parts) is built layer by layer within the powder bed.

Cooling: Once printing is complete, the entire build chamber, filled with unfused powder surrounding the parts, moves to a cooling station. Controlled cooling is crucial for achieving optimal material properties and dimensional stability.

Depowdering: After cooling, the build unit is transferred to a depowdering station. Parts are carefully excavated from the unfused powder, which is sieved and recycled for future builds (typically achieving very high reuse rates).

Image Courtesy of Formlabs

Materials Compatible with MJF

|

MJF Material |

Key Properties |

Best Applications |

|

PA12 (Nylon 12) |

High strength, stiffness, chemical resistance, durability |

Functional prototypes, end-use parts, enclosures, gears |

|

PA11 (Nylon 11) |

Higher impact resistance, flexibility, bio-based |

Sports equipment, snap fits, parts requiring impact absorption |

|

PA12GB (Glass-filled) |

Increased stiffness, thermal resistance, dimensional stability |

Rigid housings, fixtures, high-temp applications |

|

TPU |

Flexibility, elasticity, abrasion resistance |

Grips, seals, gaskets, cushioning, wearable parts |

|

Polypropylene |

Chemical resistance, fatigue strength, living hinges |

Fluid handling, containers, living hinges |

Advantages of MJF 3D Printing

1. Superior Part Quality: Excellent mechanical properties, fine details, smooth surfaces, and isotropic behavior.

2. High Productivity: Significantly faster than SLS or many other industrial processes, especially for full build volumes. Batch production is highly efficient.

3. Cost-Effectiveness: Lower per-part costs compared to other high-quality processes like SLS, especially for medium volumes. High powder reusability reduces material waste.

4. Design Freedom: Handles complex geometries, internal channels, lattices, and thin walls without requiring support structures (parts are supported by surrounding powder).

5. Consistency & Reliability: Highly repeatable process ensures consistent part quality across builds and batches.

6. Good Surface Finish: Parts emerge smoother than SLS, often requiring less post-processing for many applications.

7. Functional Material Properties: MJF printed nylon parts (especially PA12) are strong, durable, and suitable for demanding environments.

Limitations of MJF 3D Printing

1. Limited Color Palette: Parts are typically produced in black or gray directly from the printer. Color can be added through dyeing (limited palette) or painting.

2. Surface Texture: While smoother than SLS, as-printed surfaces have a slightly grainy texture. Achieving a polished or glossy finish requires significant post-processing.

3. Material Restrictions: While growing, the material selection is still narrower than traditional manufacturing or some other 3D printing technologies (like FDM). Primarily focused on nylons, TPU, and PP.

4. Feature Size: Very fine details (below ~0.5mm) or extremely thin walls might be challenging due to powder particle size and the fusing process.

5. Initial Cost: Industrial MJF printers represent a significant capital investment, making online MJF printing services an attractive route for most users.

Post-Processing Options for MJF Parts

Depowdering & Basic Cleaning

Removal of excess powder from surfaces and internal channels using compressed air and brushes. This is essential.

Vibratory Tumbling

Using fine media (like glass beads) under pressure to clean surfaces further and achieve a uniform matte finish.

Dyeing

Immersing parts in hot dye baths (usually black) to achieve a deeper, more uniform color throughout the part, hiding the natural gray of the powder.

Vapor Smoothing

Using chemical vapors to slightly melt the outer surface, resulting in a significantly smoother, near-glossy finish. Enhances aesthetics and can slightly improve sealing. Can affect fine details.

Painting & Coating

Applying primers, paints, or functional coatings for specific colors, textures, UV protection, or chemical resistance.

Tapping/Threading

Adding precise threaded holes or modifying specific features using traditional machining techniques after printing.

MJF Printed Parts Applications

Functional Prototyping

Rapidly produce high-fidelity prototypes that look, feel, and perform like final injection-molded parts for rigorous testing and validation.

Jigs, Fixtures & Tooling

Manufacture durable, custom workholding devices, assembly aids, and gauges that improve production line efficiency and ergonomics.

End-Use Parts

Produce final components for products, especially for low-to-medium volume production, complex designs, or where traditional tooling is cost-prohibitive. Examples include housings, brackets, ducting, gears, and covers.

Medical Devices

Create biocompatible (specific PA12 grades) components for surgical guides, instrument handles, prosthetics, and custom orthopedic devices.

Automotive

Produce under-hood components, fluid connectors, brackets, cable management clips, and custom interior parts.

Aerospace

Manufacture ducting, lightweight brackets, housings for avionics, and cabin interior parts (using validated materials).

Consumer Goods

Develop ergonomic handles, complex sporting goods components, electronic enclosures, and fashion accessories.

Image Courtesy of Hi3DP

Factors that Affect the MJF Printed Part Cost

Volume: MJF excels at batch production. The more parts packed efficiently into a single build, the lower the cost per part due to amortizing machine time and setup.

Part Size: Larger parts consume more material and occupy more build volume, increasing cost.

Material Choice: Standard PA12 is generally the most economical. Specialty materials like PA11, TPU, or PA12GB command a premium.

Powder Consumption: Parts with high volume/surface area ratios use more powder. Hollow designs can reduce this.

Post-Processing: Basic bead blasting is often included. Dyeing, smoothing, painting, or complex machining add significant cost.

Labor & Overhead: Service provider costs including machine amortization, labor, facilities, and profit margin.

Order Complexity: Handling, setup, and file preparation for highly complex orders.

How to Order MJF 3D Printing Services at Hi3DP

Ordering MJF 3D printing service online with Hi3DP is streamlined and user-friendly:

1. Upload Your Design: Visit the Hi3DP website and upload your 3D model file (STL, STEP, OBJ, 3MF preferred). Our system accepts multiple files for batch quoting.

2. Configure Your Order: Select your desired material (PA12, PA11, TPU, PA12GB, PP), choose your finish (Basic Bead Blasted, Dyed Black, Smoothed/Vapor Polished), specify quantity, and select any additional options (e.g., expedited shipping).

3. Instant Online Quote: Our automated quoting engine analyzes your design, material usage, build volume efficiency, and selected options to provide a real-time, competitive price. No waiting for email quotes!

4. Design Analysis (Optional but Recommended): Utilize our automated design analysis tools or request a manual review by our engineers. We'll check for potential issues like wall thickness, trapped powder, or feature size and provide suggestions for optimization.

5. Review & Approve: Review the quote, design feedback, and estimated lead time. Approve the order securely online.

6. Secure Payment: Complete payment using our secure online payment gateway.

7. Production & Shipping: Once approved and paid, your parts enter our production queue. We print, post-process, carefully inspect, and promptly ship your high-quality MJF printed nylon parts directly to you. Track your order easily online.

Image Courtesy of Hi3DP

FAQs

Q: What is the typical lead time for MJF parts from an online service?

A: Standard lead times are typically 3-5 business days for production + shipping time, depending on order size and complexity. Many services, including Hi3DP, offer expedited options.

Q: Can MJF parts be used outdoors?

A: Standard nylons (PA12, PA11) are susceptible to UV degradation over prolonged exposure. For outdoor use, parts should be painted with UV-resistant paint, coated, or made from UV-stabilized materials (if available). PA12GB has slightly better UV resistance.

Q: How accurate is MJF 3D printing?

A: MJF offers high accuracy, typically within ± 0.3% of the model dimensions. Factors like part geometry, material shrinkage during cooling, and orientation can influence final tolerances. Critical dimensions should be specified.

Q: Can MJF print multi-colored parts?

A: Not directly during printing. MJF parts are printed in a single material color (black or gray). Multi-color effects require post-processing like painting or dyeing specific sections.

Q: Is MJF better than SLS?

A: MJF generally offers faster print speeds, lower per-part costs (especially for full builds), better surface finish out of the printer, and often higher detail resolution compared to SLS. SLS may have a slightly wider material range in some niches. MJF is often considered the successor technology to SLS.