Selective Laser Sintering (SLS) has transformed how engineers, designers, and manufacturers approach prototyping and low-to-mid-volume production. In this guide, we’ll explore everything you need to know about SLS 3D printing, from the basics of how it works to material choices, costs, and how to compare prices at Hi3DP’s online SLS printing service.

What is SLS 3D Printing

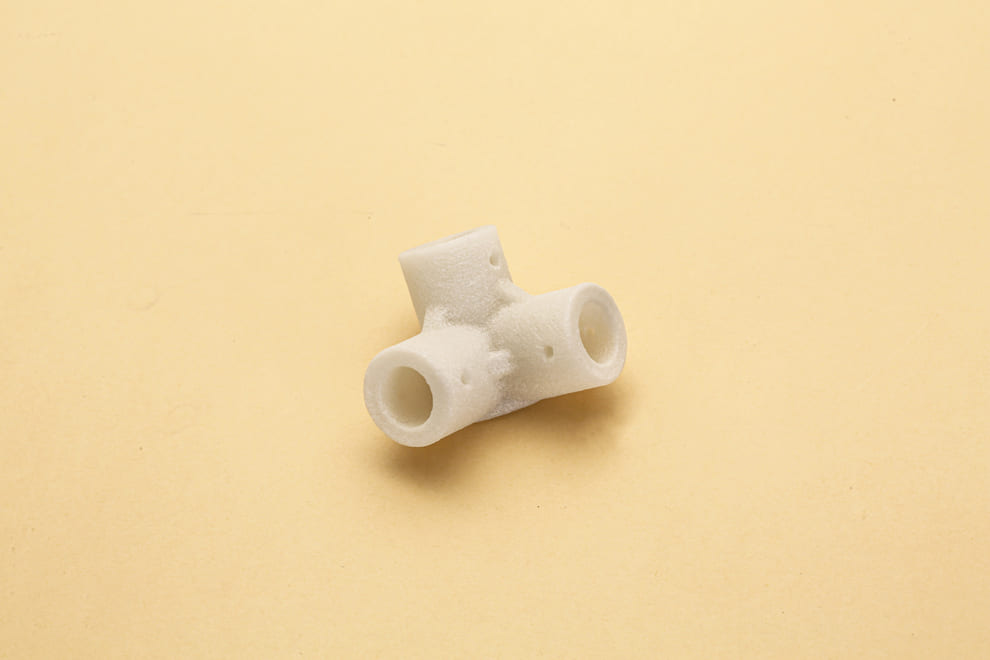

Selective Laser Sintering (SLS) is an additive manufacturing process that uses a high-power laser to fuse powdered material—commonly nylon—layer by layer into solid, three-dimensional parts. Unlike FDM or SLA, SLS doesn’t require support structures because the unsintered powder acts as its own support, which makes it ideal for complex geometries, interlocking assemblies, and parts with internal cavities.

Key aspects of SLS 3D printing:

No supports needed: simplifies design and post-processing.

Isotropic mechanical properties: uniform strength in all directions.

Versatile applications: from functional prototyping to end-use components.

Create durable and fully functional parts: ideal for testing, end use and low-volume production without tooling investments.

Image Courtesy of Hi3DP

How SLS 3D Printing Works

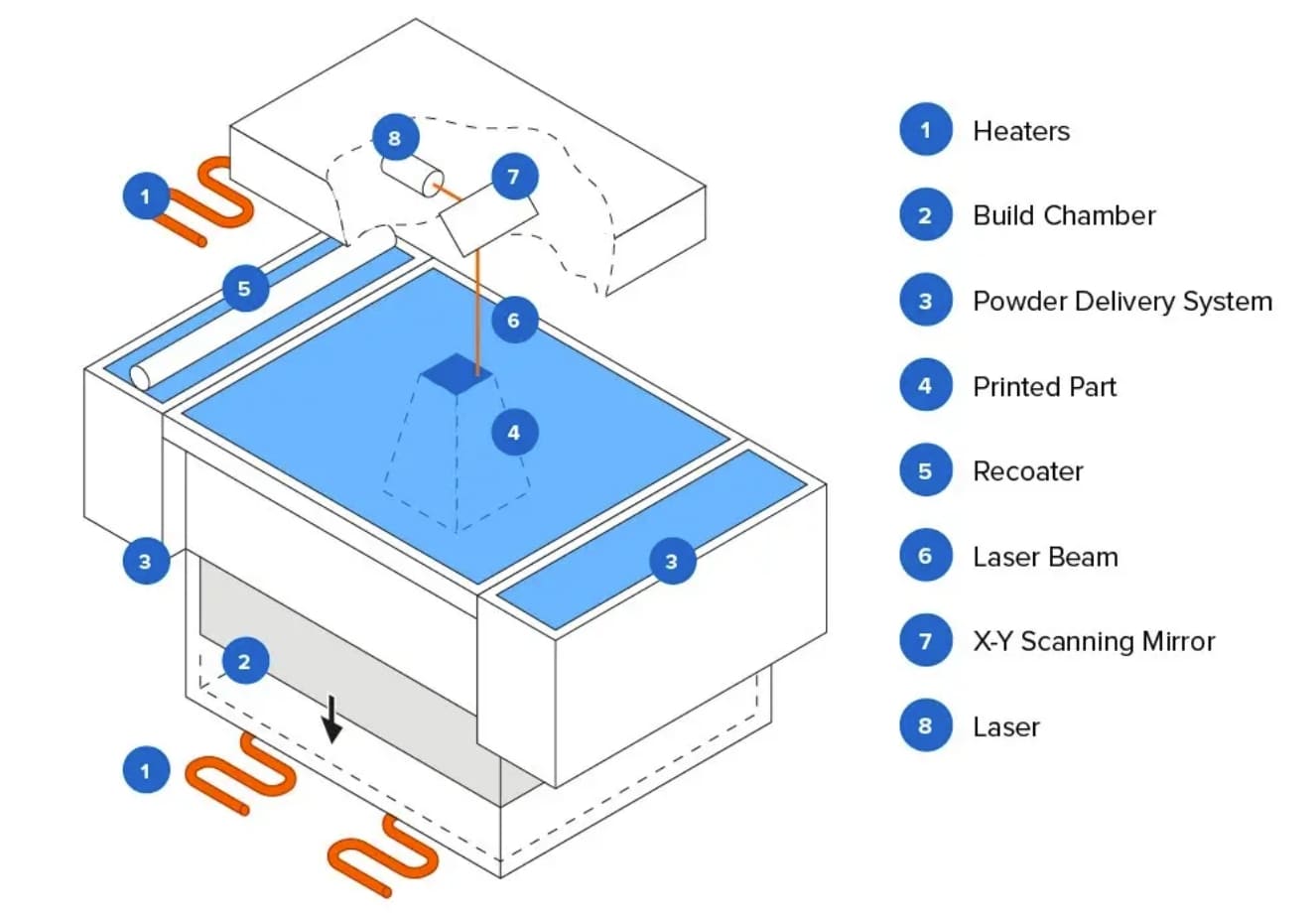

1. Powder Deposition

A thin layer (typically 50–120 µm) of powdered polymer (e.g., nylon) is spread across the build platform by a recoater blade.

2. Laser Scanning

A CO₂ laser selectively sinters the powder according to cross-sectional data from the 3D model, fusing particles together.

3. Layering Cycle

After one layer is sintered, the build platform lowers by one layer height, and a fresh powder layer is applied. This repeats until the part is fully built.

4. Cooling

Once the print completes, the entire powder bed cools within the build chamber to avoid thermal stresses and warping.

5. Unpacking & Recycling

The build cake is removed, and parts are excavated from the loose powder. Unused powder—typically ~70–80%—is sieved and recycled for future builds.

Image Courtesy of Formlabs

Materials Used in SLS

Material selection is critical to achieving the desired mechanical, thermal, and aesthetic properties. Common SLS printed nylon powders and other engineering-grade thermoplastics include:

1. PA12 (Nylon 12)

The most widely used material in SLS printing, known for its excellent balance of strength, flexibility, chemical resistance, and detail resolution.

Use cases: Functional prototypes, housings, enclosures, snap fits.

2. PA11 (Nylon 11)

A biobased nylon derived from castor oil. Offers improved ductility and impact resistance over PA12.

Use cases: Flexible parts, wearable components, impact-prone applications.

3. PA6 (Nylon 6)

Known for higher mechanical strength and heat resistance compared to PA12. However, PA6 is more difficult to process and more sensitive to moisture.

Use cases: Structural parts, industrial tooling, load-bearing applications.

4. Glass-Filled Nylon (PA12 GF / PA6 GF)

Nylon infused with 15–40% glass beads or fibers to improve stiffness, dimensional stability, and heat deflection temperature.

Use cases: Automotive under-hood parts, jigs and fixtures, components requiring high rigidity.

5. Carbon-Filled Nylon

Reinforced with carbon fibers to offer high stiffness and strength at reduced weight, with improved electrical conductivity.

Use cases: Lightweight aerospace and robotics components.

6. TPU (Thermoplastic Polyurethane)

A flexible, rubber-like material suitable for elastomeric parts. Offers excellent wear and tear resistance.

Use cases: Gaskets, seals, cushioning, wearable devices.

7. Polypropylene (PP)

A chemically resistant and flexible polymer known for fatigue resistance and ductility. It’s ideal for living hinges and chemical containers.

Use cases: Fluid reservoirs, tubing, snap-fit lids.

8. Glass-Filled PP

Enhances the stiffness and temperature resistance of polypropylene while maintaining its chemical resilience.

Use cases: Automotive parts, industrial tanks, chemical-handling components.

9. Polycarbonate (PC)

An engineering-grade plastic offering outstanding toughness, transparency, and thermal performance. Less common in SLS due to higher melting points, but available with advanced systems.

Use cases: Protective covers, housings exposed to heat or impact, electrical components.

Image Courtesy of Hi3DP

Advantages of SLS 3D Printing

1. Complex Geometry: Produce lattice structures, internal channels, and overhangs without support structures.

2. Part Strength & Durability: Isotropic properties yield consistent mechanical performance across axes.

3. High Throughput: Batch production of multiple parts in a single build, reducing per-unit cost.

4. Material Versatility: Wide range of nylon grades and specialty powders for functional requirements.

5. Surface Finish: Fine detail resolution (~0.1 mm), with post-processing options for smooth or colored finishes.

6. Minimal Tooling: No molds or fixtures required, enabling rapid iteration and low-volume manufacturing.

Limitations of SLS 3D Printing

1. Surface Texture: Parts have a matte, slightly grainy finish. Requires bead blasting or tumbling for a smoother look.

2. Cost Considerations: Higher equipment and material costs than FDM. Ideal for mid- to high-value parts.

3. Build Chamber Size: Limited by machine dimensions; very large parts may need segmentation and assembly.

4. Porosity & Moisture Sensitivity: Nylon absorbs moisture, which can affect mechanical properties and print quality. Proper storage and drying are essential.

5. Color Limitations: Standard powders come in natural (off-white or gray). Coloring requires dyeing or painting post-process.

SLS 3D Printed Parts Applications

1. Aerospace & Defense

Lightweight brackets, ducting, and fixtures that must withstand harsh environments.

2. Automotive

Custom jigs, prototypes, functional end-use parts like intake manifolds and air ducts.

3. Medical & Dental

Patient-specific surgical guides, orthotic braces, custom tooling, and anatomical models.

4. Consumer Electronics

Housings, connectors, and internal components requiring tight tolerances.

5. Industrial Tooling

Sprues, jigs, fixtures, and production aids for injection molding and CNC.

6. Retail & Fashion

Customized eyewear, wearable accessories, and ergonomically optimized goods.

Image Courtesy of Hi3DP

Post-Processing Used in SLS

Powder Removal

nce printing is complete, SLS parts are surrounded by loose, unsintered powder. The first step is powder removal, which involves using compressed air, brushes, or bead blasting to clean the surface, which ensures the parts are free of debris and ready for use or further finishing.

Dyeing

Dyeing is a popular method for adding color to SLS printed nylon parts, especially PA12. Parts are submerged in heated dye solutions, allowing the color to penetrate the porous surface. This process provides consistent coloration and is more durable than surface painting.

Painting

Painting allows for custom finishes and color matching that dyeing can’t achieve. It involves priming the surface and then applying spray paint or airbrush coatings, making it ideal for aesthetic parts or prototypes where branding and presentation are important.

Vapor Smoothing

Vapor smoothing enhances the surface finish by exposing parts to a controlled chemical vapor that gently melts the outermost layer. This results in a smoother, glossier appearance and reduced porosity, which is useful for sealing parts or improving hygiene.

Vibratory Smoothing

Also known as tumbling, vibratory smoothing uses abrasive media in a vibrating chamber to polish the surface of SLS parts. It helps reduce surface roughness and create a more uniform finish, making it suitable for both functional and aesthetic applications.

Screen Printing

Screen printing is used to add text, logos, or graphics directly onto the surface of SLS parts. It works by pushing ink through a stencil onto the part, providing a precise and durable method to add branding or labels without altering the part's geometry.

Image Courtesy of Hi3DP

Cost and Lead Time

Several factors influence SLS pricing:

Material Cost:

Nylon powders range from $50 to $150 per kilogram, depending on the specialty grade.

Machine Time:

Laser run time and build chamber occupancy. Typical hourly rates range from $50 to $100.

Powder Recycling Rate:

Unused powder (~70–80%) is reusable, reducing effective material costs over time.

Labor & Post-Processing:

Setup, unpacking, media tumbling, dyeing, and inspection.

Batch Size & Nesting Efficiency:

More parts per build lower per-unit costs. Optimal nesting yields minimal void space.

Lead Time depends on order complexity and service provider capacity:

Standard turnaround: 3–7 business days

Expedited service: 1–2 business days (additional fee)

Compare Price of SLS Printed Parts at Hi3DP

At Hi3DP, our SLS 3D printing service delivers competitive pricing, transparent quoting, and streamlined online ordering.

1. Instant Online Quotes: Upload your CAD files to receive an immediate, all-inclusive quote that includes materials, labor, and post-processing.

2. No Hidden Fees: Transparent breakdown of costs—machine time, powder usage, and finishing.

3. Volume Discounts: Economies of scale as part volume increases.

4. Global Shipping: Fast, insured delivery to your facility.

By comparing Hi3DP against typical market rates, you can see significant savings—especially for small to medium runs. Our user-friendly platform makes ordering your SLS printed nylon parts as easy as a few clicks.

Image Courtesy of Hi3DP

FAQs

Q: What tolerances can I expect with SLS parts?

A: Standard dimensional tolerances are ±0.3 mm or ±0.3% of feature size.

Q: How thick should walls be in SLS?

A: Minimum wall thickness is typically 0.8–1.0 mm for PA12. For glass- or carbon-filled nylons, increase to 1.2–1.5 mm to ensure structural integrity.

Q: How does SLS compare to SLA and FDM?

A: Versus SLA: SLA offers smoother surfaces and finer detail, but SLS parts are stronger and more durable for functional use.

Versus FDM: FDM is lower cost but limited in complexity and isotropy. SLS provides superior mechanical performance and support-free builds.

Q: What post-processing options seal parts against moisture?

A: Beyond drying, sealing techniques like vapor smoothing (melting a thin surface layer) and specialized coatings can reduce porosity and moisture uptake.

Q: Is SLS only for making prototypes?

A: No. Although widely used for functional prototyping, SLS also serves for small- to mid-volume production parts. Many aerospace, automotive, and consumer-goods manufacturers rely on SLS for end-use components.