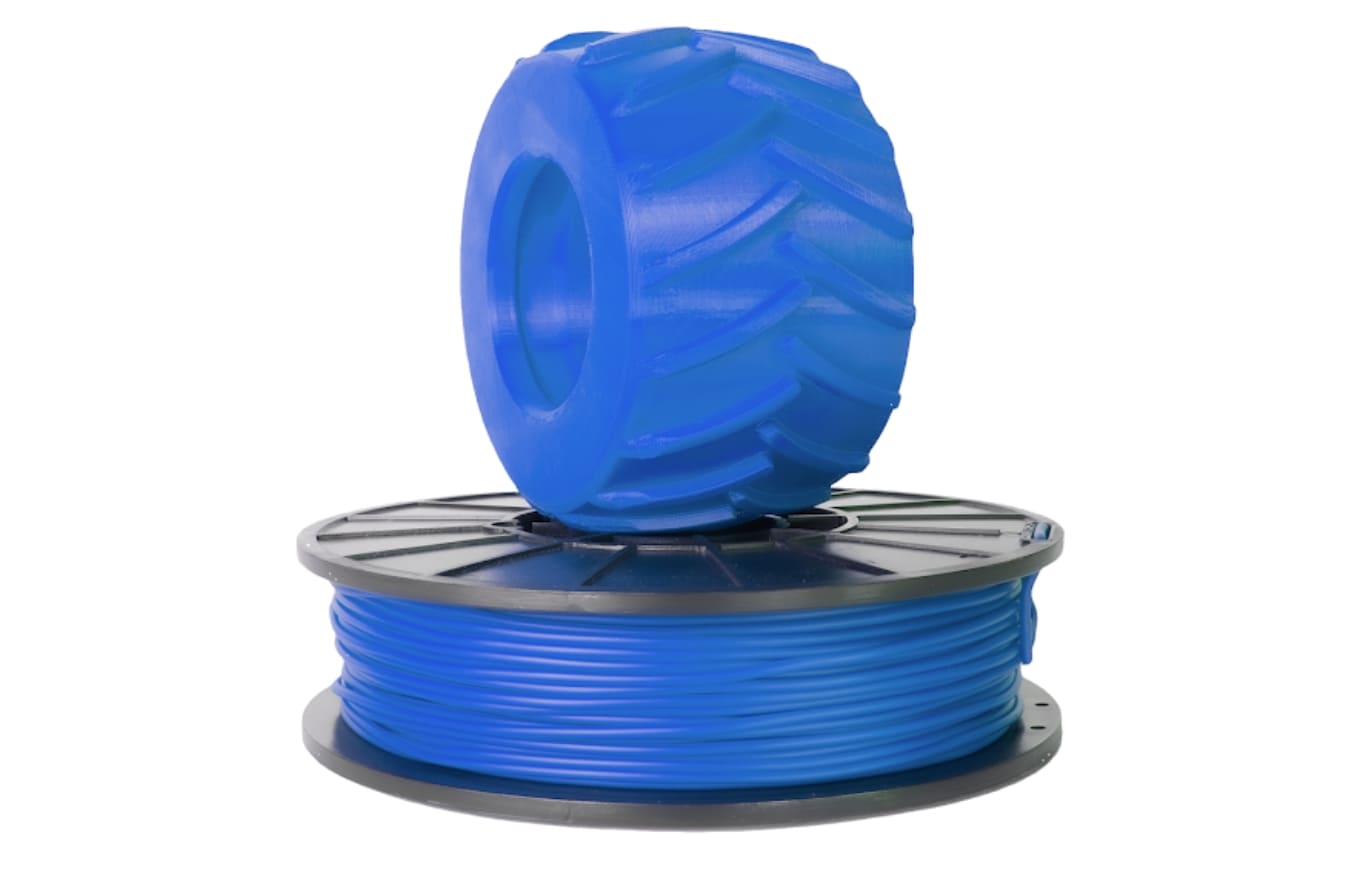

Banner Image Courtesy of MatterHackers

What Is 3D Printer Filament?

A filament is a thermoplastic material, typically supplied on a spool as a continuous strand of precise diameter (commonly 1.75 mm or 2.85 mm). During printing with an FDM (Fused Deposition Modeling) 3D printer, the filament is fed into a heated extruder nozzle, melting the plastic and depositing it layer by layer onto the build platform. As each layer cools, it stiffens and bonds to the previous layer, gradually forming a three-dimensional object.

Key Components of Filament

Base Polymer: This is the primary material—PLA, ABS, PETG, Nylon, TPU, and so on. Each base polymer has unique thermal, mechanical, and chemical properties that determine how it prints and performs.

Additives or Fillers: Some filaments contain wood fibers, metal powders, carbon fiber strands, or other additives to give specific aesthetics or improved mechanical strength. These are collectively referred to as composite filaments (covered in Part 3).

Diameter Tolerance: High-quality filaments maintain a consistent diameter within ±0.03 mm. Variations beyond that can lead to under-extrusion (gaps in your print) or over-extrusion (blobs, stringing).

Packaging and Dryness: Many filaments are inherently hygroscopic—they absorb moisture from the air over time, which can cause steaming, bubbling, or poor layer adhesion. That’s why reputable brands often vacuum-seal spools and include desiccant packs.

Selecting the correct filament type is critical for achieving a successful print—whether you’re printing a decorative figurine, a functional bracket, or a flexible wearable.

Image Courtesy of MatterHackers

Common Filament Types and Their Properties

1. PLA (Polylactic Acid)

PLA is a biodegradable thermoplastic derived from renewable resources such as cornstarch or sugarcane.

|

Printing Temperature |

190–220 °C |

|

Bed Temperature |

45–60 °C (often prints fine on an unheated bed) |

|

Key Properties |

Minimal warping and excellent bed adhesion make PLA the go-to choice for beginners. PLA emits a sweet, almost nonexistent smell compared to ABS. Produces glossy prints with crisp detail. |

|

Applications |

Prototypes, decorative models, educational projects, low-stress mechanical parts. |

|

Limitations |

Relatively low heat resistance (glass transition around 60 °C). Parts can deform if exposed to high temperatures (e.g., a hot car dashboard). |

2. ABS (Acrylonitrile Butadiene Styrene)

A petroleum-based thermoplastic known for toughness and impact resistance.

|

Printing Temperature |

220–250 °C |

|

Bed Temperature |

90–110 °C (often requires an enclosed build chamber to avoid warping) |

|

Key Properties |

Higher impact resistance than PLA and better heat resistance (glass transition ~105 °C). Can be acetone-smoothed to achieve glossy surfaces and seamless finishes. |

|

Applications |

Functional parts (enclosures, brackets), automotive prototypes, consumer products (LEGO bricks are made of ABS). |

|

Limitations |

Produces noticeable fumes during printing; good ventilation is essential. Without an enclosure, large ABS parts can lift from the bed at corners, causing warping. |

3. PETG (Polyethylene Terephthalate Glycol-Modified)

A glycol-modified variant of PET that blends the best traits of PLA and ABS.

|

Printing Temperature |

230–250 °C |

|

Bed Temperature |

70–90 °C |

|

Key Properties |

Comparable tensile strength to ABS with better layer adhesion. Resists water, most acids, and mild solvents. Tends to stay flat on the bed, making large prints easier. |

|

Applications |

Functional mechanical parts, water-tight containers (if properly sealed), food-safe prints (using food-grade PETG). |

|

Limitations |

PETG can ooze or string if retraction settings aren’t dialed in. |

4. TPU/TPE (Thermoplastic Polyurethane/Elastomer)

Flexible, rubber-like filaments that compress and rebound while maintaining strength.

|

Printing Temperature |

210–240 °C (varies by brand) |

|

Bed Temperature |

40–60 °C (optional, but improves bed adhesion) |

|

Key Properties |

High elongation at break (200–400%), allowing for durable, bendable prints. Ideal for grips, bumpers, and wearable items that need to flex. |

|

Applications |

Phone cases, gaskets, wearable accessories, flexible hinges, drone landing pads. |

|

Limitations |

Requires a direct-drive extruder to handle the filament’s softness. Bowden systems can jam or grind the filament. Print speeds should be kept around 20–30 mm/s to maintain control. |

5. Nylon (Polyamide)

A semi-crystalline polymer prized for its toughness, abrasion resistance, and thermal stability.

|

Printing Temperature |

240–260 °C |

|

Bed Temperature |

70–100 °C (enclosure recommended) |

|

Key Properties |

Excellent tensile strength (often >50 MPa) and good flexibility under load. Ideal for gears, bushings, and moving mechanical assemblies. |

|

Applications |

Functional gears, mechanical parts, structural prototypes, snap-fit hinges. |

|

Limitations |

Absorbs moisture quickly. Wet Nylon will steam, sizzle, and produce poor layer adhesion—drying filament before use is mandatory. Prone to warping if the build chamber is not maintained around 35–45 °C. |

6. PET (Polyethylene Terephthalate)

The non-glycol-modified version of PETG. Less forgiving than PETG but still widely used for functional prints.

|

Printing Temperature |

230–250 °C |

|

Bed Temperature |

70–90 °C |

|

Key Properties |

Slightly more brittle than PETG, with excellent clarity in transparent variants. Layer adhesion is good, though not quite as strong as PETG’s. |

|

Applications |

Mechanical parts, water-tight containers, prosthetics, OEM prototypes. |

|

Limitations |

Like all polyesters, PET can absorb moisture, leading to bubbles. |

Specialty and Composite Filaments

1. Wood-Filled Filaments

|

Composition |

PLA infused with 20–40% fine wood fibers (bamboo, cedar, cork, or exotic hardwood species). |

|

Printing Tips |

Print at slightly higher temperatures (205–220 °C) to accommodate the wood fibers. Use a nozzle ≥0.4 mm to reduce clogging from wood particles. Keep print speeds moderate (30–50 mm/s) for consistent extrusion. |

|

Applications |

Decorative items, signage, custom furniture accents, cosplay props, souvenir items. |

2. Metal-Filled Filaments

|

Composition |

PLA or another polymer mixed with 50–80% fine metal powder (bronze, copper, stainless steel, brass). |

|

Printing Tips |

• Print at 210–230 °C, slightly higher than standard PLA. • Use a hardened steel or ruby-tipped nozzle, as metal powders are abrasive and wear out brass nozzles quickly. • Slow speeds (20–40 mm/s) help avoid under-extrusion. |

|

Applications |

Jewelry prototypes, statues, functional parts that benefit from added weight, high-end decorative items. |

3. Carbon Fiber–Reinforced Filaments

|

Composition |

Base polymer (most commonly Nylon or PETG) infused with 5–20% short carbon fiber strands. |

|

Printing Tips |

• Maintain a nozzle temperature of 240–260 °C (for carbon-reinforced Nylon) or 230–250 °C (for PETG variants). • Print at moderate speeds (30–50 mm/s) to ensure even extrusion. • Print in a well-ventilated area—carbon fiber dust and particles can be an inhalation hazard during post-processing. |

|

Applications |

Structural components, drone frames, robotic parts, automotive prototypes, high-strength brackets. |

4. Glass-Filled and Kevlar-Filled Filaments

|

Composition |

Typically Nylon or ABS mixed with 10–30% chopped glass fiber or Kevlar strands. |

|

Printing Tips |

• Use nozzle temperatures recommended by the filament manufacturer (often 240–260 °C for glass-filled Nylon). • Print in an enclosed chamber to maintain ambient temperatures above 30 °C, reducing warping. • Consider a bed adhesion solution (glue stick or specialized adhesives) to keep the first layer anchored. |

|

Applications |

Automotive or aerospace prototypes, functional mechanical gears, heat-resistant housings, tooling jigs. |

5. Conductive Filaments

|

Composition |

PLA or ABS matrix infused with carbon black, graphene, or other conductive fillers to achieve electrical conductivity (resistivity typically in the kΩ/cm range). |

|

Printing Tips |

• Print at 200–220 °C for PLA-based conductive filaments. • Keep print speeds around 30–40 mm/s to ensure consistent deposition. • For multi-material electronics, pair conductive filament with standard PLA or PETG, pausing the print to insert wires or components. |

|

Applications |

Basic printed circuits, sensor housings, capacitive touch interfaces, educational STEM projects. |

6. Flexible Filaments with Variable Shore Hardness

|

Composition |

TPU/TPE filaments come in different Shore hardness ratings. Common variants include Shore 85A (softer, more rubbery) and Shore 95A (stiffer, like a firm rubber). |

|

Printing Tips |

• Lower speeds (20–30 mm/s) to prevent filament buckling in the extruder. • Direct-drive extruders offer better control; Bowden setups can cause filament binding. • Print a test cube to dial in retraction (often 1–2 mm at 25–30 mm/s) to minimize stringing. |

|

Applications |

Wearable gadgets, flexible hinges, gaskets, grips, orthopedic soles, shock-absorbing mounts. |

Material Properties and How They Affect Print Performance

1. Tensile Strength and Flexural Modulus

Tensile Strength

Measured in megapascals (MPa), this is the maximum stress a material can withstand while being stretched before breaking.

Why It Matters: For functional parts—gears, brackets, mechanical linkages—you need a filament with a tensile strength high enough to resist operational loads without snapping.

Flexural Modulus

Indicates a material’s stiffness—how much it resists bending under load.

Why It Matters: If your design requires rigidity (e.g., a structural frame or prototype), a higher flexural modulus means the part will flex less under force.

2. Elongation at Break (Ductility)

Expressed as a percentage, this measures how far a material can stretch before it fractures.

Why It Matters: Components that must deform—like snap-fit joints or flexible hinges—benefit from a filament with high elongation at break (e.g., TPU or certain flexible PLA blends).

3. Impact Strength

The ability of a material to absorb energy from a sudden blow without fracturing.

Why It Matters: Parts subject to sudden shocks (e.g., protective casings, mechanical couplings) should use materials with elevated impact resistance to avoid cracking under stress.

4. Glass Transition Temperature (Tg) and Melting Temperature (Tm)

Tg (Glass Transition Temperature)

The temperature at which an amorphous polymer (like PLA or ABS) transitions from a hard, glassy state to a softer, rubbery state.

Why It Matters: If you expose a PLA part to direct sunlight (e.g., a part mounted on a car’s dashboard that can reach 70 °C), it will soften or warp. For applications requiring elevated temperature resistance, choose a filament with a Tg above your operating conditions.

Tm (Melting Temperature)

The temperature at which a semi-crystalline polymer (e.g., Nylon) fully melts.

Why It Matters: Knowing Tm helps you set appropriate nozzle temperatures. Overheating above Tm for extended periods can degrade polymers, while underheating can cause poor layer adhesion.

5. Moisture Absorption (Hygroscopic Nature)

The propensity of a filament to absorb moisture from the air.

Why It Matters: If you skip drying hygroscopic filaments, you risk print failures and weakened parts. For Nylon, TPU, PVA, and some specialty composites, always dry the filament before printing.

6. Coefficient of Thermal Expansion (CTE)

The rate at which a material expands or contracts in response to temperature changes, measured in μm/m·K or ×10⁻⁶/°C.

Why It Matters: High CTE materials shrink more as they cool, inducing internal stresses that can lead to warping and layer separation. Low CTE materials (like PLA) are more dimensionally stable on cooling, making it easier to print large objects reliably.

7. Surface Finish and Detail Resolution

How smooth or textured the printed surface appears is often influenced by layer height and material composition.

Why It Matters: If your project demands glossy, injection mold-like surfaces, choose a filament known for smooth finishes (e.g., PLA, PETG). For rustic or specialty aesthetics (e.g., wood grain or metal patinas), composite filaments shine, even if you sacrifice micron-level detail.

Image Courtesy of MatterHackers

Storage, Handling, and Pre-Printing Preparation

1. Store Filament Dry and Dust-Free

Vacuum-Sealed Bags

When you open a new spool, transfer it to a resealable bag with a desiccant pack. Replace the desiccant if it changes color (usually every couple of months).

Filament Dry Boxes or Cabinets

For moisture-sensitive materials (Nylon, TPU, PVA), use a dry box that holds the spool and keeps humidity low. Some dry boxes also heat the filament slightly as it feeds to the extruder—ideal for longer prints.

Avoid Direct Sunlight and Dust

Store filaments in a cool, dark place to prevent UV degradation (which can make some filaments brittle). Keep filaments away from open windows or vents to minimize dust buildup.

2. Dry Filaments Before Printing (Especially Hygroscopic Ones)

When to Dry

If the filament snaps easily when bent, produces popping sounds in the nozzle, or prints with tiny surface bubbles, it’s likely absorbed moisture.

Drying Methods

Filament Dryer: Follow the manufacturer’s recommended temperature and time (e.g., 80 °C for 4–6 hours for Nylon; 50 °C for 2–3 hours for PLA).

DIY Oven or Food Dehydrator: Set to the appropriate temperature and let the spool sit for the suggested time. Make sure the heat is accurate (avoid temperatures above the filament’s glass transition or melting point).

3. Handle Filament Carefully During Prints

Prevent Snags and Tangles

Always secure the end of the filament when you pause or finish a print to avoid unwinding. Use a filament guide or simple PTFE tubing so the filament feeds smoothly from the spool to the extruder.

Clean the Filament Path

Wipe a few centimeters of filament with a lint-free cloth or an alcohol wipe before loading it to remove dust. For dusty workspaces, consider a “filament sponge” (a foam block soaked in isopropyl alcohol) placed in the filament path to trap debris.

4. Inspect Filament Visually and Dimensionally

Check for Brittleness

Gently bend a 5–10 cm segment; it should flex slightly. If it snaps, dry or replace it.

Measure Diameter

Use a digital caliper to measure the diameter at several points. Enter the average value into your slicer to ensure consistent extrusion.

5. Quick Pre-Print Machine Checks

Nozzle Temperature Test

Print a small “temperature tower” (a model with sections at different nozzle temperatures). Look for the smoothest layers without stringing.

Bed Leveling and First Layer

Use a sheet of paper or a feeler gauge to set the nozzle-to-bed gap so the first layer is slightly compressed (e.g., ~0.15 mm if you print at 0.2 mm layer height). If your printer has auto-bed leveling, still verify with a visual test on each new build surface.

Extruder Calibration (E-Steps)

Mark 120 mm on your filament above the feeder. Instruct the printer to extrude 100 mm. Measure how much actually moved. Adjust the steps per millimeter in your firmware or slicer until the extruded length matches exactly.

Image Courtesy of MatterHackers

How to Choose the Right Filament for Your Project

1. Define Your Project Requirements

Mechanical Strength vs. Flexibility

If the part must bear loads, resist bending, or withstand impacts (e.g., robotic arm components), choose filaments with high tensile strength and flexural modulus: ABS, PETG, Nylon, or Carbon fiber–-reinforced blends.

For parts that need to bend, compress, or stretch (e.g., snap-fit joints, phone cases, wearable accessories), flexible filaments like TPU (Shore 85A or 95A) are ideal.

Temperature Resistance

If the end-use environment reaches elevated temperatures (e.g., engine bay components, under-the-hood prototypes), PLA isn’t a safe choice (Tg ~60 °C). Instead, opt for ABS (Tg ~105 °C), PETG (Tg ~80 °C), Nylon (Tm ~220–260 °C), or specialty high-temperature filaments (PEEK, PC).

For room-temperature functional parts, PLA, PETG, and standard ABS usually suffice.

Chemical or UV Exposure

For parts exposed to mild chemicals, solvents, or oils (like lab jigs or mounting brackets for solvent containers), PETG or Nylon are safer options. ABS can handle certain chemicals but may degrade over time under UV light.

For outdoor parts prone to sun exposure (e.g., garden tools), PLA will fade and become brittle; ASA (Acrylonitrile Styrene Acrylate) or PETG with UV stabilizers perform better.

2. Evaluate Aesthetic Needs

Surface Finish

If you need a glossy, injection-mold-like look (e.g., display models, collectible figurines), PLA or PETG are excellent choices.

For matte finishes or unique textures, consider specialty filaments: wood-filled for a natural grain, stone-filled for a textured “marble” feel, or metal-filled for a semi-polished sheen.

Color Fidelity and Specialty Effects

Standard PLA and PETG come in a vast spectrum of vibrant colors. Some brands offer pigments with consistent color saturation across spools.

Specialty filaments such as glow-in-the-dark, thermochromic (color-changing with temperature), or translucent variants can provide eye-catching effects for signage, cosplay props, or educational demos.

3. Assess Printer Compatibility and Setup

Nozzle Material

Standard brass nozzles are suitable for PLA, ABS, PETG, and most flexible filaments.

Abrasive filaments—carbon fiber, glass fiber, metal-filled—wear down brass nozzles quickly. Invest in hardened steel, stainless steel, or ruby-tipped nozzles to maintain consistent extrusion and prolong nozzle life.

Extruder Type

Bowden Extruder: The filament travels through a longer PTFE tube, requiring higher retraction (4–6 mm), but can struggle with very flexible filaments.

Direct-Drive Extruder: The extruder motor sits right above the hot end, providing immediate pushing force—ideal for TPU, TPE, and other flexible materials. If you print primarily with flexible filaments, consider a direct-drive upgrade or a hybrid extruder that supports flexible materials.

Build Plate and Adhesion

Unheated or Lightly Heated Bed: Adequate for PLA and some PETG (≥50 °C). Use blue painter’s tape, PEI sheets, or glue sticks to improve adhesion.

Heated Bed (70–110 °C): Required for ABS, PETG, Nylon, and certain composites to prevent warping.

Enclosure: ABS, Nylon, and high-temperature filaments benefit from a chamber kept around 35–50 °C to reduce thermal shock and warping. An enclosure can be as simple as a cardboard box or as advanced as a fully integrated heated chamber with temperature control.

4. Factor in Budget and Brand Reliability

Cost per Kilogram

Entry-level PLA spools often start around $20–$30/kg. Standard ABS or PETG range from $25–$40/kg. Specialty filaments—wood-filled, carbon fiber–filled, metal-filled—can cost $50–$100/kg or more.

Investing in reputable brands may cost slightly more upfront but reduces the risk of diameter inconsistencies, impurities, and moisture-related failures. Consider flagship brands with tight diameter tolerances (±0.02 mm) if dimensional accuracy is critical.

Filament Certifications

Some filaments (especially PETG and nylon) come with food-safe or medical-grade certifications. Verify that the entire printing pathway (e.g., nozzle material, extruder gear, build plate) is also food-safe if you plan to print utensils, containers, or medical prototypes.

5. Environmental and Post-Processing Considerations

Biodegradability

PLA is compostable under industrial conditions, making it a greener choice for disposable prototypes or educational use.

ABS, PETG, Nylon, and many composites are not biodegradable. If sustainability is important, investigate recycled PLA or PETG filaments made from post-consumer materials.

Post-Processing Requirements

Sanding and Painting: For a smooth finish, PLA, ABS, and PETG can be sanded and painted easily. Metal-filled filaments require extra effort to polish, while wood-filled filaments can be sanded and stained like real wood.

Acetone or Solvent Smoothing: ABS and some ABS blends (ASA) can be smoothed with acetone vapor. PETG can also be smoothed with specific solvents, though less common.

Dyeing and Staining: Certain composite filaments (wood-filled, stone-filled) respond well to wood stains or dyes, allowing you to achieve authentic color palettes.

Image Courtesy of MatterHackers

FDM Printing Tips for Optimized Outcomes

|

Tip Category |

Recommendation |

|

Temperature Settings |

• Nozzle: Print a small temperature tower (±5 °C around manufacturer’s spec) to find optimal extrusion—smooth layers without stringing. • Bed: PLA (50–60 °C), PETG (70–80 °C), ABS (90–110 °C). Adjust to prevent warping. • Cooling Fan: PLA: 100 %; PETG: 30–50 %; ABS: 0–20 %. |

|

Print Speed & Acceleration |

• PLA: 40–60 mm/s; PETG/ABS: 30–50 mm/s; TPU: 20–30 mm/s. • Acceleration/Jerk: For quality, set acceleration to 1,500–2,500 mm/s² and jerk to 8–12 mm/s; increase only for fast drafts. |

|

Retraction Settings |

• Bowden Extruder: 4–6 mm retract at 40–60 mm/s. • Direct-Drive: 1–3 mm at 30–50 mm/s. • Enable coasting or wipe in slicer to reduce blobs and stringing. |

|

Layer Height & Nozzle |

• Standard: 0.4 mm nozzle, 0.2 mm layer height (50% of nozzle). • Fine Detail: 0.1 mm layer on 0.4 mm nozzle; slow speeds for consistency. • Fast Drafts: 0.3–0.35 mm layer height to save time. |

|

Bed Adhesion |

• Surface Prep: PLA: blue painter’s tape or glue stick. PETG: PEI sheet or thin glue. ABS/Nylon: ABS slurry or Kapton tape. • Adhesion Aids: Brims (5–10 rings) for small parts; rafts for highly warp-prone filaments. • Enclosure: Recommended for ABS and Nylon to maintain ~35–45 °C chamber. |

|

Environment & Maintenance |

• Ambient Conditions: Keep room at 20–25 °C, humidity <40 %. Avoid drafts. • Nozzle Cleaning: Cold-pull or replace nozzle every 20–30 print hours or after abrasive materials. • Belt Tension: Ensure belts are neither too loose (layer shifting) nor too tight (motor strain). • Rod Lubrication: Light machine oil on smooth rods to maintain smooth motion. |

Troubleshooting Common Filament-Related Issues

|

Issue |

Symptoms |

Common Causes |

Quick Fixes |

|

Filament Jams / Nozzle Clogs |

• Under-extrusion or no extrusion • Clicking/clicking noises from extruder |

• Impurities in cheap filament • Overheated/burnt plastic • Mixing incompatible materials without purge |

• Perform a cold pull (cleaning filament) • Replace nozzle (use a hardened one for composites) • Clean hotend path |

|

Stringing / Oozing |

• Fine “hairs” between features • Blobs on surface |

• Nozzle temperature too high • Insufficient retraction settings • Slow travel moves |

• Lower nozzle temperature in 5 °C steps • Increase retraction distance/speed (Bowden: 4–6 mm @40–60 mm/s; Direct: 1–3 mm @30–50 mm/s) • Enable coasting/wipe in slicer |

|

Warping / Corner Lifting |

• Corners of print lifting off bed • Distorted bottom layers |

• High thermal contraction (ABS, Nylon) • Poor bed adhesion • Ambient drafts/cold spots |

• Use an enclosure to maintain ~35–45 °C • Apply brims (5–10 outlines) or rafts • Improve adhesion (ABS slurry, Kapton, PEI, glue stick) |

|

Poor Layer Adhesion / Delamination |

• Layers peeling under slight pressure • Weak, easily snapped parts |

• Nozzle temperature too low• Printing too fas t• Moist filament causing steam bubbles |

• Raise nozzle temperature by 5–10 °C • Slow print speed by 10–20 mm/s for better bonding • Dry filament (use filament dryer or oven) |

|

Brittle / Inconsistent Filament |

• Filament snaps under slight pressure • Popping/sizzling during extrusion • Irregular extrusion |

• Moisture absorption (Nylon, TPU, PVA) • UV/age degradation |

• Dry filament at recommended temperature/time (e.g., Nylon: 80 °C for 4–6 h; TPU: 50 °C for 2–3 h) • Store in dark, low-humidity area |

|

Under- or Over-Extrusion |

• Gaps between lines (under) • Bulging, excess plastic (over) |

• Incorrect E-steps calibration • Filament diameter mismatch in slicer settings • Partial nozzle clog |

• Calibrate E-steps: extrude a known length and adjust steps/mm • Measure filament diameter (use average in slicer) • Clean or replace nozzle |

|

Surface Imperfections: Blobs / Zits / Ringing |

• Small raised blobs or pits on walls • Ripples or echo patterns around corners |

• Inconsistent retraction • Loose belts or rods causing vibration • High acceleration/jerk |

• Enable coasting/wipe to reduce excess extrusion • Tighten belts, check rod lubrication • Lower acceleration (1,500–2,500 mm/s²) and jerk (8–12 mm/s) |

FAQs

Q: What filament is best for beginners?

A: For those just starting with FDM 3D printing, PLA filament is by far the friendliest option.

Q: How do I know if my filament has absorbed too much moisture?

A: The filament snaps easily when bent instead of flexing. During extrusion, moisture trapped inside the filament flashes to steam, creating small cracks or bubbles. Printed parts may show tiny craters or sub-layer voids.

Q: Can I mix filament types in a single print?

A: Yes, with a dual-extrusion printer or a multi-material upgrade like the Prusa MMU2S.

Q: How often should I calibrate my printer’s extrusion settings?

A: As a rule of thumb, check your E-steps (extrusion steps per millimeter) every 50–100 print hours or whenever you:

Swap nozzles (especially when changing diameter or material).

Notice under- or over-extrusion that isn’t solved by changing filament or temperature.

Upgrade or modify your extruder assembly.

Q: What are some general cleaning and maintenance tips for filament-friendly printing?

A: Nozzle Inspection: Check for any visible plastic buildup around the nozzle tip before each major print. If you see residue, perform a cold pull or replace the nozzle.

Filament Path Cleaning: Occasionally feed a strip of cleaning filament (nylon or specialized cleaning filament) through your extruder at 200 °C to clear dust and tiny debris.

Build Plate Upkeep: Clean glass beds with isopropyl alcohol before each print. Replace PEI sheets if they become scratched or lose adhesion.

Dry Storage: Maintain an organized filament storage system—vacuum-sealed bags with desiccant for active spools and closed cabinets or dry boxes for long-term storage.