(Banner Photo Courtesy of Jakub Zerdzicki)

FDM (Fused Deposition Modeling) is the most widely used 3D printing technology, known for its affordability and versatility. It works by melting and extruding a plastic filament layer by layer to build solid parts, making it ideal for rapid prototyping and custom manufacturing. This guide explains FDM 3D printing comprehensively — what it is, how it works, its pros and cons, materials used, and cost drivers.

What is FDM 3D Printing? (Fused Deposition Modeling)

Definition

Fused Deposition Modeling (FDM) is an additive manufacturing technology that constructs objects by melting and depositing thermoplastic filament layer-by-layer through a heated nozzle. Notably, "FDM" is a trademarked term owned by Stratasys; the generic equivalent for this process is Fused Filament Fabrication (FFF).

History

Pioneered by Scott Crump in 1989, FDM emerged as the first widely adopted 3D printing method. Originally developed for industrial applications by Stratasys, the technology later became the foundation for the affordable desktop 3D printers prevalent today.

Terminology

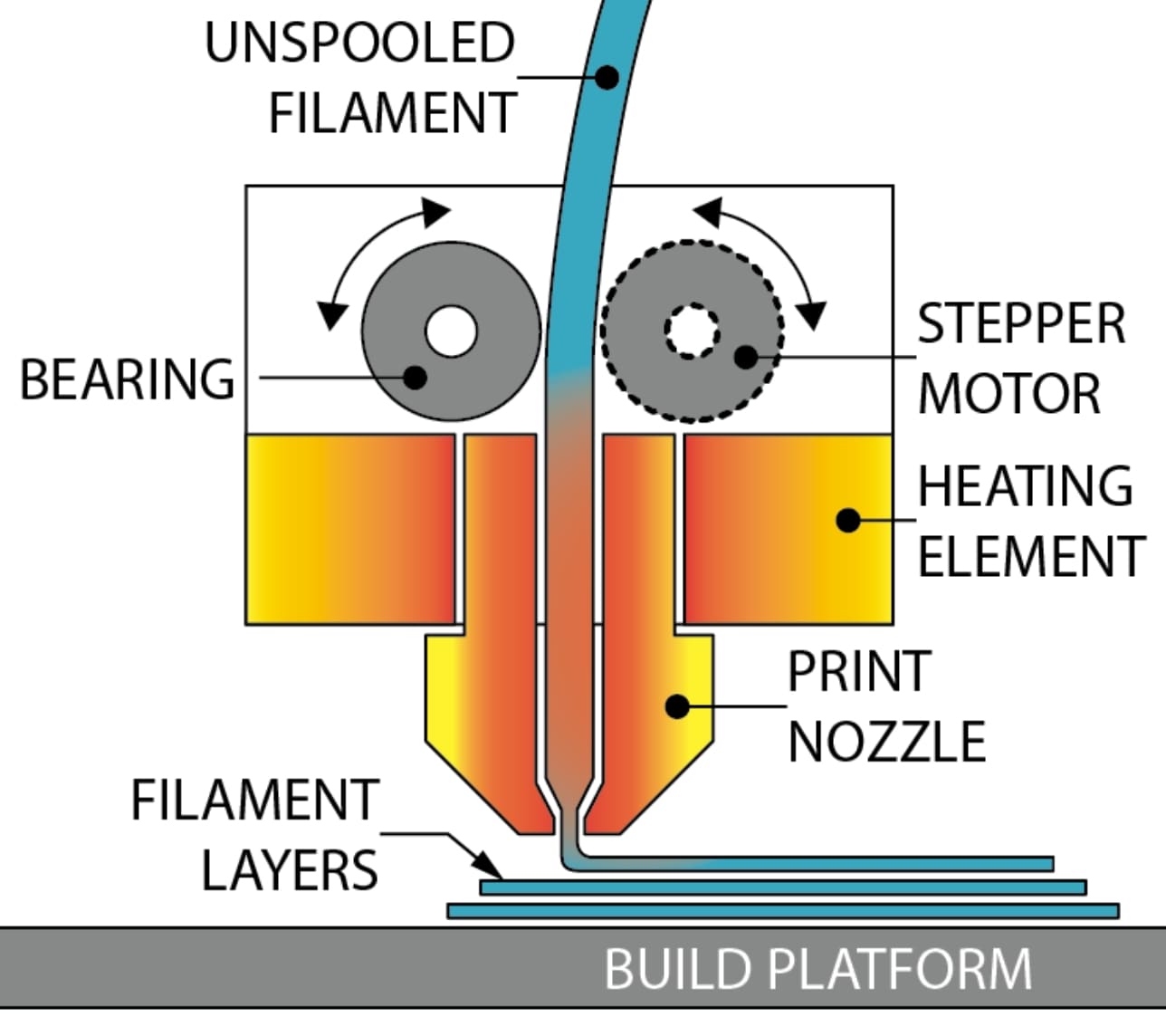

• Filament: The raw material, typically plastic, is supplied in spools with standard diameters of 1.75 mm or 2.85 mm.

• Extruder: A mechanism that heats the filament to a molten state and forces it through a precision nozzle (e.g., ~0.4 mm diameter) to create each layer.

• Process Classification: A subset of material extrusion in additive manufacturing, characterized by controlled deposition of melted material.

Images Courtesy of Stratasys

How FDM 3D Printing Works

1. Control & Slicing Workflow:

A digital 3D model is processed by slicing software, which divides it into hundreds of thin horizontal layers and generates machine-readable G-code. This code dictates printer movements, extrusion rates, and parameters such as layer height (commonly 0.1–0.3 mm), print speed, and temperature. Adjusting these settings allows optimization for speed, resolution, or material properties.

2. Filament Feeding & Extrusion:

In FDM/FFF printing, thermoplastic filament (e.g., PLA, ABS, PETG, TPU) is fed from a spool into an extrusion mechanism. The filament is heated beyond its melting point within the extruder, liquefying the material, which is then precisely dispensed through a nozzle along a predefined toolpath.

3. Layer-by-Layer Construction:

The printer’s motion system positions the nozzle along the X and Y axes to deposit molten material, forming a single horizontal layer of the object. After completing a layer, the Z-axis adjusts (typically by 0.1–0.3 mm) to begin the next layer, which bonds thermally with the previous layer as the material cools. This incremental stacking creates the final 3D structure, with layer adhesion influencing overall strength.

4. Supports & Thermal Management:

Support Structures: For geometries with overhangs or bridges, removable or dissolvable supports are printed to prevent sagging during fabrication. These are manually or chemically removed post-print.

Cooling Systems: Integrated fans actively cool freshly extruded material to accelerate solidification, minimizing deformations. Cooling strategies vary by material—PLA benefits from rapid cooling, while ABS often requires controlled thermal conditions to reduce warping.

Images Courtesy of Instructables

Advantages of FDM 3D Printing

Cost-Effectiveness: FDM is generally the least expensive 3D printing method for plastic parts. Desktop FDM printers are affordable, and material costs are low. Protolabs notes FDM “is more cost-effective than any additive manufacturing technology”, making it ideal for budget-conscious projects.

Material Variety: FDM supports a wide range of thermoplastic filaments, from basic PLA and ABS to flexible (TPU) and engineering plastics (Nylon, PETG, PC, PEI). The versatility lets users choose materials for strength, flexibility, heat resistance, or chemical resistance as needed.

Ease and Accessibility: FDM printers are widely available—from hobbyist machines (under $200) to industrial units. The technology is well-understood, and there are many user-friendly printers and software. FDM is good for rapid prototyping and education.

Scalability and Size: FDM printers can have very large build volumes. It’s practical for big parts (like car or drone components) by using larger nozzles and layer heights to speed up printing. Larger parts only increase cost linearly with volume.

Fast Turnaround (for Prototypes): For coarse prototypes, FDM can be fast. Short lead times (often days) are common for simple print. Quick cycles of design-iterate-test are possible in-house or via service.

Limitations of FDM 3D Printing

Lower Resolution: FDM has the coarsest layer detail of common 3D printing methods. Layer heights are typically ≥0.1 mm, so very small features (<1 mm) and perfectly smooth surfaces are difficult. Prints often show visible layer lines. Compared to SLA resin printing (which can do ~0.2 mm walls), FDM minimum wall thickness is around 0.8 mm.

Surface Finish: Because of visible layers, FDM parts usually need post-processing (sanding, polishing, acetone smoothing) to achieve a smooth finish, which adds time and cost if a refined appearance is required.

Anisotropic Strength: FDM parts can be weaker along layer boundaries. The bonding between layers is not as strong as within a layer. Anisotropy means parts can snap or delaminate under stress perpendicular to the print layers. Designers often orient parts to mitigate this.

Support Structures: Any overhangs or complex geometries require support material during printing. These supports must be removed afterward, which adds material usage, print time, and manual labor. FDM is less efficient for complex shapes than SLS (which often requires no supports).

Surface Defects and Tolerances: Minor defects (like stringing or blobs) can occur. FDM’s dimensional accuracy is generally lower than high-end industrial processes. Typical tolerances might be ±0.5–1.0 mm or 0.1–0.2% of size, depending on the machine and calibration.

FDM vs. Other 3D Printing Methods

|

Tech |

Full Name |

Process |

Key Attributes |

Speed |

Finish & Post-processing |

Applications |

Cost |

|

Fused Deposition Modeling |

Thermoplastics (ABS, PLA, PETG) extruded layer-by-layer |

Moderate strength (anisotropic), Low detail |

Slow |

Rough; sanding/vapor smoothing |

Prototypes, jigs, simple parts |

$ |

|

|

Stereolithography |

UV-cured photopolymer resin |

Brittle, High detail, Smooth |

Fast |

Smooth; UV post-cure |

Dental, jewelry, precision models |

$$ |

|

|

Selective Laser Sintering |

Laser-sintered nylon powders |

High strength, Dense, Grainy finish |

Moderate |

Grainy; powder removal |

Functional parts, complex geometries |

$$$ |

|

|

Multi Jet Fusion |

Fuses nylon powder with agents |

High strength, Isotropic, Fine detail |

Fast |

Smooth; minimal post-processing |

End-use nylon parts, rapid production |

$$$ |

|

|

Selective Laser Melting |

Laser-melted metal powders |

Dense metal, High strength, Rough surface |

Slow |

Requires machining/polishing |

Aerospace, medical implants |

$$$$ |

|

|

Binder Jetting |

Binder Jetting |

Binds powder (metal/sand) layer-by-layer |

Porous pre-sintering, Medium detail |

Very Fast |

Requires sintering/infiltration |

Casting molds, color prototypes |

$$ |

FDM 3D Printed Applications

1. Rapid Prototyping: FDM is excellent for quickly producing concept models, form-and-fit prototypes, and proof-of-concept parts. Its low cost and speed make it perfect for early-stage design iterations.

2. Low-Volume Manufacturing: Small production runs, jigs, fixtures, tooling aids, and custom or replacement parts are often made with FDM. For small quantities (tens to hundreds), FDM can be cheaper than creating molds or using injection molding.

3. Education and Makerspaces: FDM’s affordability and ease of use make it popular in classrooms, universities, and maker spaces. Learners can experiment with 3D design and printing without large investments.

4. Automotive and Aerospace: Engineers use FDM for rapid prototyping of dashboards, ductwork, brackets, and more. In aerospace and automotive, lightweight FDM parts (often with carbon-fiber filaments) can be used for tooling or even some functional components.

5. Healthcare and Dental: Custom jigs, surgical guides, orthotic supports, and anatomical models are commonly FDM printed because each can be tailored to a patient affordably. Medical offices and labs often use FDM for in-house model printing.

6. Consumer Products: For short-run products, props, prototypes of gadgets, or customizable items (phone cases, toys, household fixtures), FDM is a go-to solution. Its color filament variety lets designers quickly proof different aesthetics.

7. Engineering and Functional Parts: With engineering-grade filaments (e.g., Nylon, PC, PEI), FDM can produce durable end-use parts. For example, injection mold masters, functional prototypes, and low-stress mechanical parts often use FDM materials.

8. Cost-Sensitive Uses: Because it’s budget-friendly, any industry or hobby where cost is a key factor tends to favor FDM.

Images Courtesy of Stratasys

Common Materials (Filaments) for FDM

|

Material |

Key Properties |

Cost (USD/kg) |

Common Uses |

Considerations |

|

Biodegradable, food-safe, easy to print, low heat resistance |

~$20–$50 |

Prototypes, decorative items, low-stress parts |

Brittle under stress, limited durability |

|

|

Durable, heat-resistant, impact-resistant |

~$20–$40 |

Automotive parts, electronics enclosures, tools |

Requires heated bed, prone to warping, emits fumes |

|

|

Tough, chemical-resistant, low warping, less brittle than PLA |

~$25–$50 |

Mechanical parts, containers, outdoor use |

Stringing issues, needs precise cooling settings |

|

|

Flexible, rubber-like elasticity |

~$30–$60 |

Gaskets, phone cases, shoe soles |

Slow print speed, requires tuned retraction |

|

|

Strong, wear-resistant, slightly flexible |

~$40–$80 |

Gears, bearings, functional tools |

Hygroscopic (needs dry storage), requires heated enclosure |

|

|

Carbon/Glass-Filled |

High stiffness, reinforced with fibers (carbon/glass) |

~$50–$100 |

Rugged parts, aerospace/automotive components |

Abrasive (use hardened nozzle), challenging to print |

|

Engineering Polymers |

Extreme heat resistance, high strength, UV/chemical resistance |

~$100–$300 |

Industrial/military parts, high-temp applications |

Requires high-end printers (heated chamber), difficult to print |

|

Specialty/Composite |

Aesthetic finishes (wood/metal-like), dissolvable supports (PVA) |

~$30–$100 |

Decorative models, prototypes with complex geometry |

Brittle (wood/metal), PVA requires humidity control |

Images Courtesy of Ultimaker

Key Factors Affecting FDM Printing Cost

Material Type and Cost

Filament choice has a big impact. Common filaments (PLA, ABS) are cheap (~$20–$50 per kg). Specialty filaments (carbon-fiber, high-temp polymers) can be 5–10× more expensive. Also consider material wastage from supports.

Print Volume (Size)

Larger models use more material and take longer to print. Costs often scale with material volume (cubic centimeters) plus machine time. More volume means higher cost.

Print Resolution (Layer Height)

Higher resolution (thinner layers) produces finer detail but increases print time significantly. For example, using 0.1 mm layers instead of 0.2 mm doubles the number of layers and roughly doubles print time. Longer print times cost more (machine-hours).

Complexity and Geometry

Intricate or hollow designs may require more supports or slower print speeds for accuracy. Complex builds can reduce printing speed and increase material usage (for supports), raising cost. Simplifying design or orientation can save money.

Print Speed and Settings

Faster printing (thicker layers, larger nozzle) reduces cost but lowers quality. High-speed modes (if available) may incur premium. The trade-off between quality and speed directly affects price.

Infill Density

Internal fill (infill) determines strength vs material usage. Lower infill uses less filament and prints faster (cheaper) but yields weaker parts. Higher infill (solid prints) means higher cost. Typical infill is 10–20% for light parts, up to 100% for fully solid parts.

Post-Processing Requirements

If a smooth finish or assembly is needed, extra steps (sanding, painting, chemical smoothing) add labor cost. Ask if the quoted price includes any finishing.

Print Quantity

Ordering multiples can reduce cost per part, since the printer can often build several in one job. Many services offer bulk or volume discounts.

Machine Type (Service Provider)

Industrial FDM printers (with closed chambers or advanced materials) often have higher operating costs than desktop units. Service bureaus factor in machine time, maintenance, and overhead.

Location and Service Fees

Regional pricing, shipping, taxes, and service bureau profit margins also affect final quotes. Comparing several providers (even internationally) can yield savings.

FDM 3D Printing FAQs

Q: How much does FDM 3D printing cost?

A: There’s no fixed price – costs vary widely by part. Small simple prints might cost just a few dollars, while large or detailed parts can be hundreds of dollars.

Q: Why is FDM usually cheaper than other 3D printing methods?

A: FDM machines and materials are generally less expensive. Thermoplastic filaments like PLA/ABS are cheap and readily available.

Q: What factors can dramatically increase the cost?

A: Key cost drivers include part size, layer height (resolution), and material choice.

Q: Is FDM suitable for precision parts?

A: FDM is fine for functional prototypes and form-fit parts, but not usually for ultra-precision or fine-feature parts.

Q: How do I compare quotes from different 3D printing services?

A: Ensure you’re comparing the same specs.