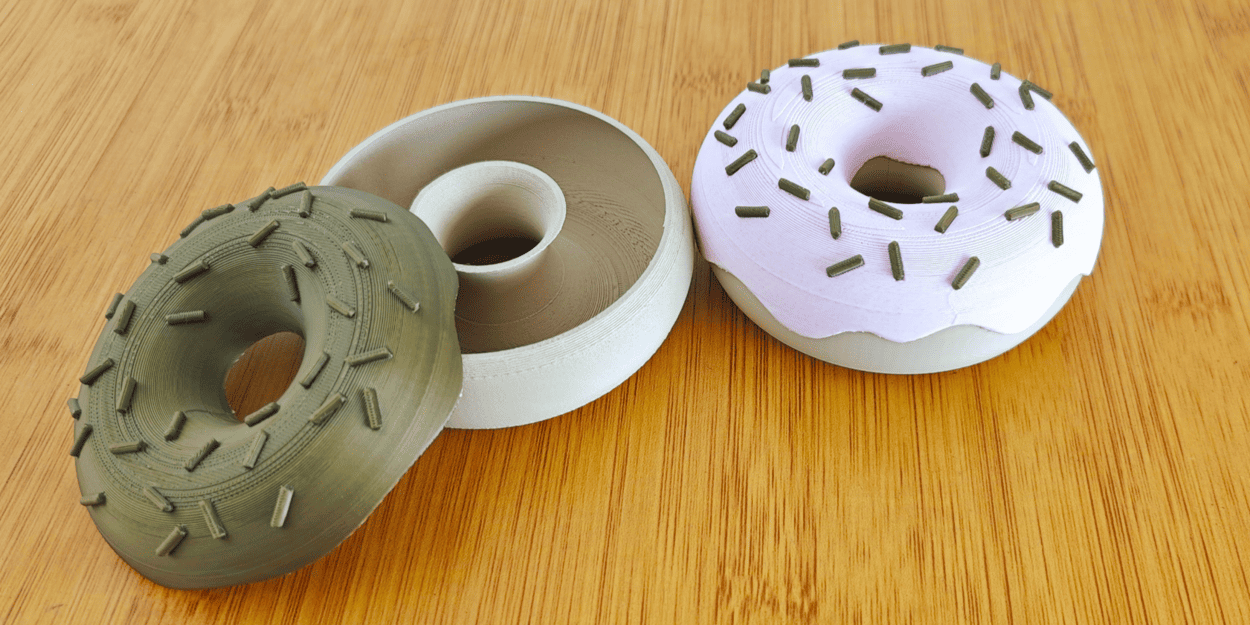

Banner Image Courtesy of Nature Hut from MakeWorld

What “Food Safe” Actually Means

“Food safe” (or “food contact safe”) is not a single universal stamp you can apply to a plastic: it’s a regulatory determination that depends on the chemical substances in the material and the way the material is used.

Regulators such as the U.S. Food & Drug Administration evaluate whether the specific substances that could migrate into food are permitted for that kind of contact, under the intended conditions (temperature, time of contact, acidic vs. fatty foods, etc.). In short, the regulatory status is determined at the substance level, not by a casual label on a roll of filament.

Practical implications:

1. A filament manufacturer can claim an FDA- or other-certified food-grade formulation, but you should request the certificate or statement of compliance (and ideally the test method).

2, Even when the raw polymer is permitted for contact, the printed object can still be unsafe because printing introduces mechanical and contamination risks (see Part 3).

Authoritative sources on this topic (FDA guidance, university fact sheets, manufacturer guidance) all stress: check certificates, consider contact time/temperature, and treat 3D printed parts differently from injection-molded commercial food containers.

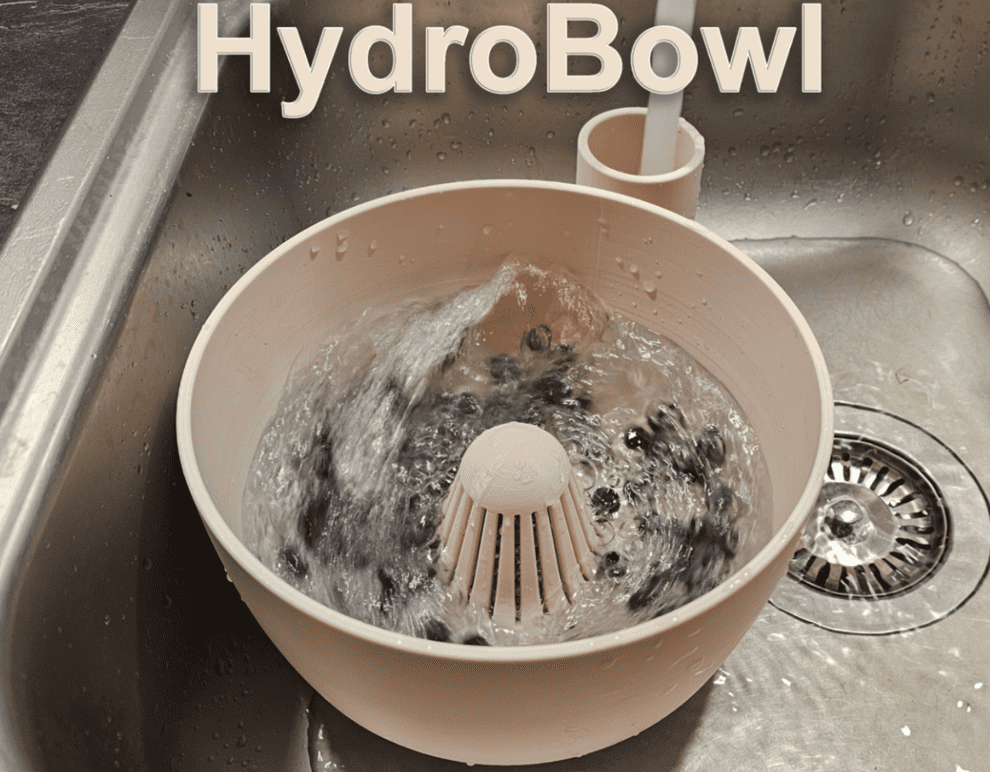

Image Courtesy of kennyklak from MakerWorld

Filaments Commonly Discussed As “Food-Safe”

Below are materials frequently mentioned by makers and manufacturers when people talk about “food-safe” 3D prints:

PETG

PETG is chemically similar to PET (bottles and food containers), and PET/PETG base polymers can be manufactured from food-grade feedstock. Many hobbyists and some vendors cite PETG as a top candidate for food-contact prints.

Not all PETG filaments are made from food-grade raw materials; additives, colorants and recycled feedstock can change that. Also, a printed PETG object still has layer lines that trap residue.

PLA (Polylactic Acid)

PLA is a bioplastic made from plant starches; in pure form, it’s often presented as less chemically risky than some petroleum plastics. Some vendors offer “food-safe PLA” grades.

Many PLA filaments contain dyes, plasticizers, or blends that are not food-grade. PLA is also brittle and more porous after printing than molded parts, so it’s best for short-contact items (e.g., cookie cutters used briefly and washed immediately) rather than utensils that hold hot or acidic food.

Polypropylene (PP)

PP is widely used for food containers and kitchenware in the industry and can be food-safe when produced and processed correctly.

PP is notoriously difficult to print (adhesion/warping), so hobbyists find it harder to achieve smooth, nonporous parts. If you can print PP well and use food-grade PP filament, it’s a good candidate technically, but process control is critical.

Nylon (Certain Grades)

Some engineering nylons have been approved for food contact in specific industrial contexts.

Nylon is hygroscopic (absorbs water), which complicates sanitation and may affect migration behavior. Many nylon filaments contain additives or glass/carbon reinforcement that are not food-safe.

Resin (SLA) and Composite/Metal-Filled Filaments

SLA resins and metal-filled filaments provide fine detail and smooth surfaces that may look promising for food contact.

Most standard SLA resins are not food-safe unless explicitly certified; many resins can leach uncured monomers. Metal- or ceramic-filled filaments introduce fillers and binders that change migration properties; treat them cautiously.

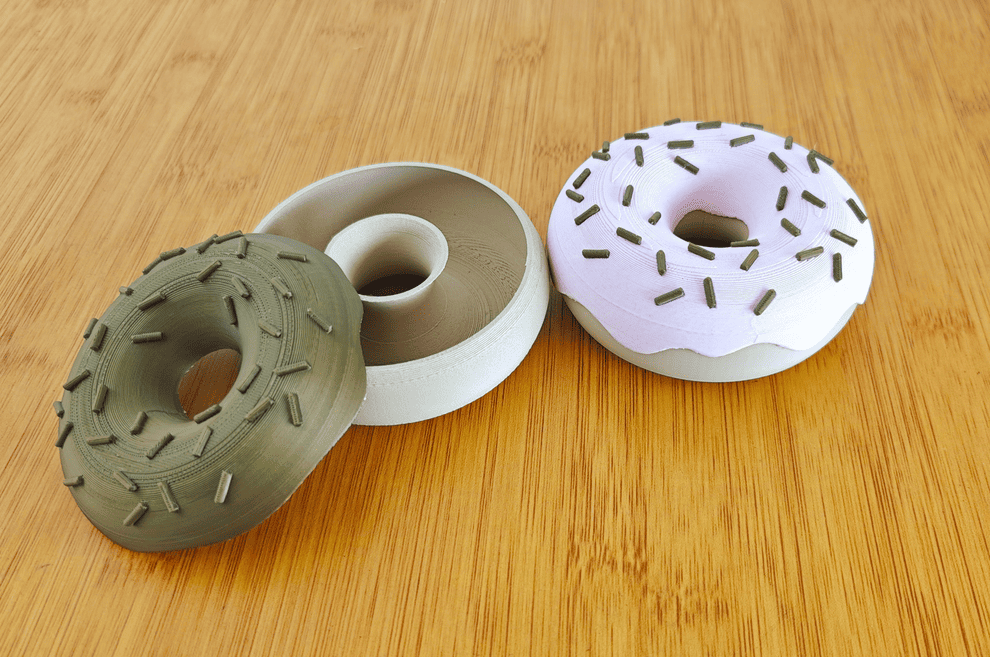

Image Courtesy of Nature Hut from MakeWorld

A Filament Being “Food-Safe” Doesn’t Automatically Make the Printed Object Food-Safe

The most important practical point for anyone publishing or using 3D printed kitchenware: a certified food-grade filament does not guarantee a food-safe printed part. The reasons are both mechanical and procedural.

1. Surface Porosity and Layer Lines

Fused filament fabrication (FDM/FFF) builds parts layer by layer. That process creates microscopic gaps, voids and roughness where food residue and bacteria can hide—areas that are difficult to reach with normal household cleaning. Multiple sources emphasize that layer-line porosity is a major bacterial-harboring risk.

2. Additives, Colorants and Contamination

Even if the base polymer is food-grade, colorants, heat stabilizers, recycled content, or contamination from a previously used hotend can introduce non-food-safe substances to the printed part. Use virgin, certified filament and a dedicated, clean extruder/nozzle for food-contact prints.

3. Printing & Post-processing Conditions

Printing temperature, cooling, under-extrusion or gaps can create weakly bonded regions that trap residue. Some studies show that effective sanitization is possible for certain materials and finishes (warm soapy water at an appropriate temperature can reduce contamination), but efficacy varies widely with print quality and post-processing. Relying on simple dishwashing is not a universal guarantee.

4. Coatings and Sealing: Helpful But Conditional

Sealing a print with a food-grade coating (for example, tested epoxy or FDA-cleared sealants) can reduce porosity and make cleaning easier—but the coating itself must be certified for food contact and applied to a fully cured, well-prepared surface. Formlabs and other manufacturers recommend food-grade sealants when attempting to use printed parts for food contact.

Practical Checklist

√ Only use filaments with a manufacturer’s food-contact statement or test data.

√ Dedicate hardware (nozzle/extruder/print bed) for food prints.

√ Print for maximum density (high extrusion multiplier, more perimeters, minimal gap bridges) and post-process (sanding + certified coating or vapor smoothing where appropriate).

√ When in doubt: don’t use 3D-printed items for long-term storage, hot/acidic foods, or applications with vulnerable populations (children, immunocompromised).