Banner Image Courtesy of Formlabs

Quick Comparison of FDM and SLA at A Glance

|

Factor |

FDM 3D Printing |

SLA 3D Printing |

|

Process |

Extrudes thermoplastic filament layer by layer |

Uses a laser to cure liquid resin layer by layer |

|

Materials |

PLA, ABS, PETG, Nylon (3D printed plastic filaments) |

Standard, tough, flexible, dental, and engineering resins (3D printed resin) |

|

Quality |

Strong, functional parts; visible layer lines |

Smooth, highly detailed, excellent surface finish |

|

Cost |

Lower machine and material cost |

Higher material and post‑processing cost |

|

Speed |

Faster for large, simple parts |

Slower due to curing and post‑processing |

|

Applications |

Prototypes, functional parts, cost‑sensitive projects |

High‑detail models, dental, jewelry, miniatures, aesthetic prototypes |

What is FDM 3D Printing?

Fused Deposition Modeling (FDM) is the most widely used form of plastic 3D printing. It works by heating and extruding thermoplastic filament through a nozzle, depositing it layer by layer to form a solid object.

Materials

PLA, ABS, PETG, Nylon, carbon‑fiber‑reinforced filaments, etc.

Applications

Functional prototypes, jigs and fixtures, low‑volume production, and educational use.

Advantages

• Affordable printers and materials.

• Durable 3D printed plastic parts.

• Easy to scale for larger builds.

Limitations

• Visible layer lines.

• Lower resolution compared to SLA.

• Limited surface smoothness without post‑processing.

FDM is often the go‑to choice when strength, cost efficiency, and speed outweigh the need for ultra‑fine detail.

What is SLA 3D Printing?

Stereolithography (SLA) is one of the earliest and most precise forms of resin‑based 3D printing. It uses a UV laser to cure liquid resin into solid layers, producing parts with exceptional detail and smoothness.

Standard resins, tough resins, high temp resins, flexible resins, dental/biocompatible resins, and engineering‑grade resins.

Applications

Dental models, jewelry, miniatures, medical devices, and high‑detail prototypes.

Advantages

• Extremely smooth surface finish.

• High resolution and fine details.

• Wide range of specialty resins.

Limitations

• More expensive materials.

• Parts can be brittle compared to FDM plastics.

• Requires post‑processing (washing, curing).

SLA excels when 3D printed resin parts need to look professional, precise, and highly detailed.

When to Choose FDM or SLA 3D Printing

Choosing between FDM 3D printing and SLA 3D printing depends on your project’s priorities:

Choose FDM if

1. You need strong, functional 3D printed plastic parts.

2. Cost efficiency is critical.

3. You’re producing larger parts where detail is less important.

Choose SLA if

1. You need smooth, detailed 3D printed resin parts.

2. Aesthetic quality is more important than strength.

3. You’re working in industries like dental, jewelry, or product design where precision matters.

The Main Differences Between FDM and SLA Printed Part Quality

When it comes to printed part quality, the differences are significant:

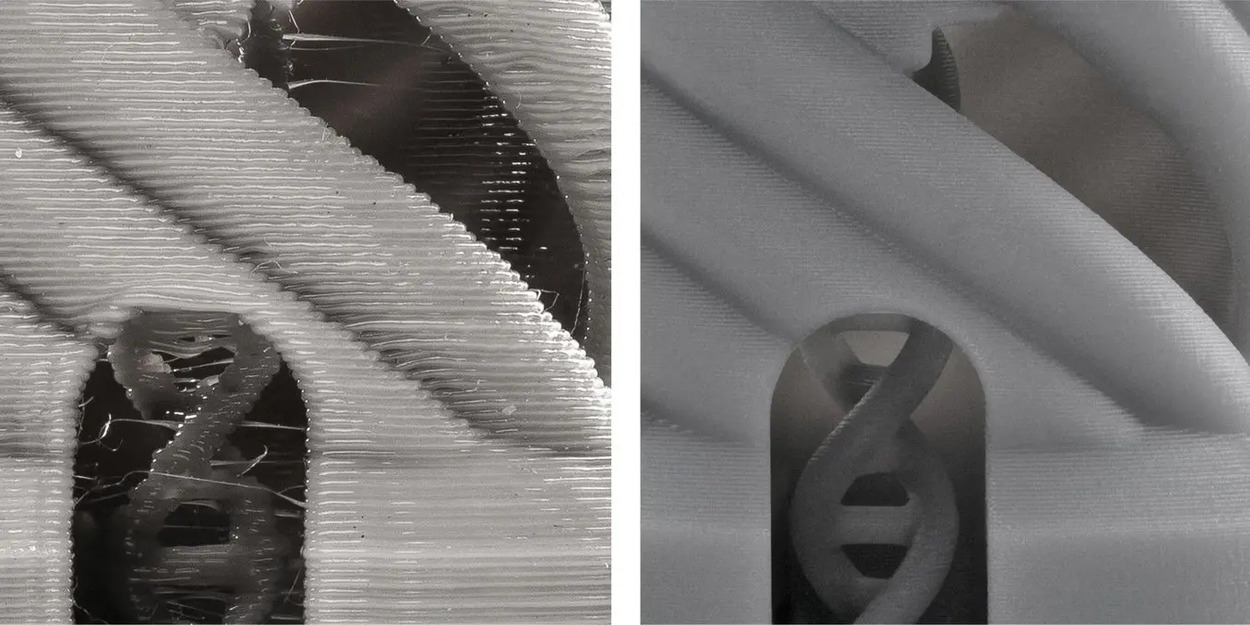

Surface Finish

• FDM parts show visible layer lines and may require sanding or vapor smoothing.

• SLA parts come out smooth with minimal finishing needed.

Detail Resolution

• FDM typically achieves layer heights of 100–200 microns.

• SLA can achieve 25–50 microns, capturing fine details.

Strength and Durability

• FDM’s thermoplastic parts are tougher and more impact‑resistant.

• SLA resins can be brittle, though engineering resins improve durability.

Dimensional Accuracy

• SLA generally offers higher accuracy for small, intricate parts.

• FDM is accurate enough for functional prototypes but less precise for fine features.

Cost Comparison

Machine Cost

• FDM printers range from a few hundred to a few thousand dollars.

• SLA printers are generally more expensive, especially industrial models.

Material Cost

• FDM filament: $20–$50 per kilogram.

• SLA resin: $80–$200 per liter.

Post‑Processing Cost

• FDM requires minimal post‑processing.

• SLA requires isopropyl alcohol, curing stations, and sometimes additional finishing.

Operational Cost

• FDM is cheaper to run long‑term.

• SLA’s consumables and maintenance add up quickly.

Speed Considerations

Speed depends on part size, complexity, and workflow:

FDM 3D Printing

• Faster for large, simple parts.

• Minimal post‑processing.

• Ideal for rapid prototyping.

SLA 3D Printing

• Slower printing due to resin curing.

• Requires washing and UV curing after printing.

• Better suited for small, detailed parts where precision matters more than speed.

If you need quick, functional prototypes, FDM wins. If you need presentation‑ready models, SLA is worth the extra time.

FAQs

Q: What is the main difference between FDM and SLA 3D printing?

A: FDM uses thermoplastic filament to create durable 3D printed plastic parts, while SLA uses liquid resin to create smooth, detailed 3D printed resin parts.

Q: Which is cheaper, FDM or SLA?

A: FDM is cheaper in both machine and material costs. SLA is more expensive but delivers higher detail.

Q: Are SLA resin parts stronger than FDM plastic parts?

A: Generally, not true. FDM parts are tougher and more impact‑resistant, while SLA parts are more precise but can be brittle.

Q: Can FDM and SLA be used together?

A: Yes. Many companies use FDM for functional prototypes and SLA for high‑detail presentation models.

Q: Which is better for plastic 3D printing overall?

A: It depends on your priorities: FDM for strength and cost, SLA for detail and aesthetics.